A large-scale machine room system and control method using micro-space water-cooled heavy-load cabinets

A control method and large-load technology, applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the problems of limited cooling capacity, large energy consumption, and high production cost of a single cabinet load, and achieve Achieve energy-saving requirements, increase energy consumption, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

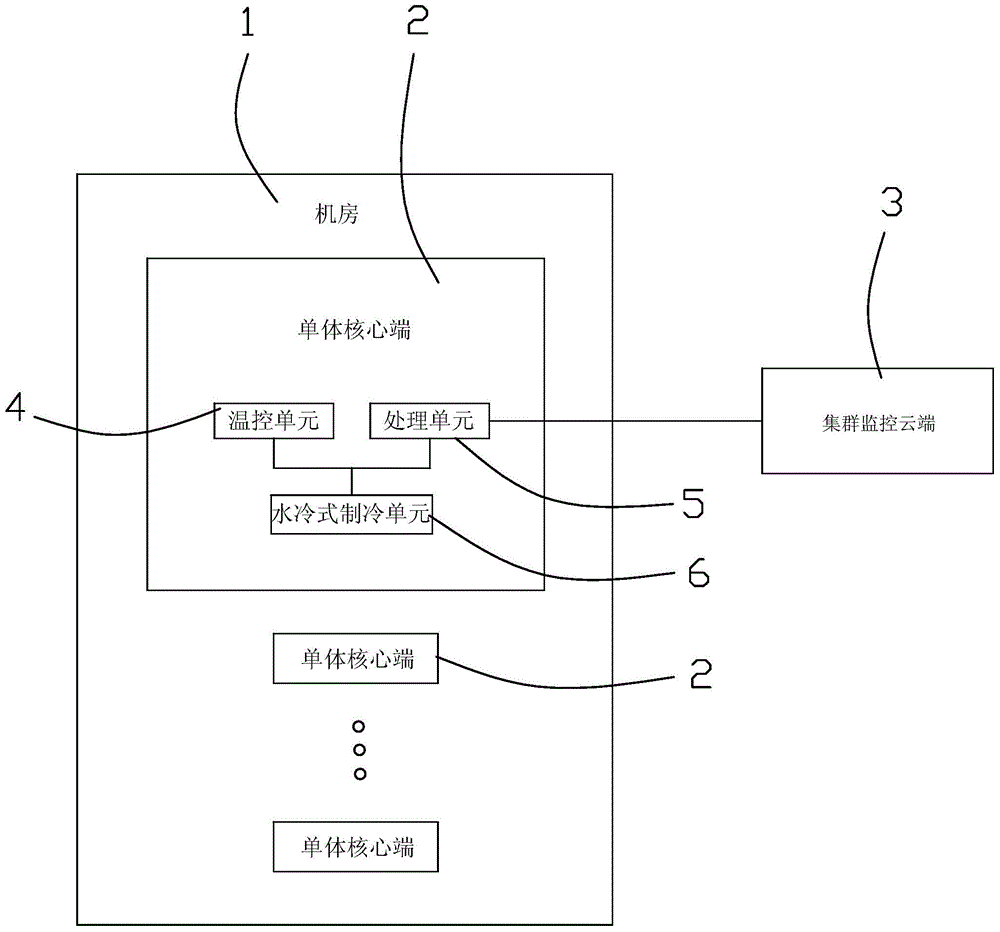

[0045] In this embodiment, a large-scale computer room system adopts micro-space water-cooled heavy-duty cabinets, such as figure 1 As shown, it includes a computer room 1 and a cluster monitoring cloud 3, and several single core terminals 2 are set in the computer room.

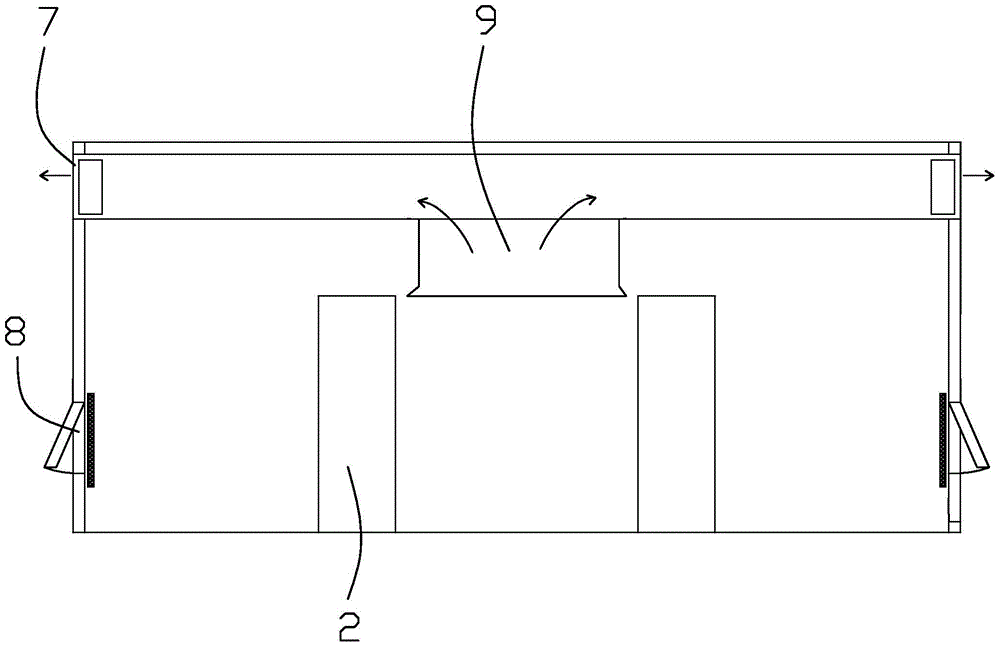

[0046] Such as figure 2 As shown, a structure of a machine room is given. Air outlets 7 are arranged on both sides of the top of the machine room, and natural air inlets 8 are arranged at the lower part of the machine room. The air outlet is connected with a ventilation pipe 9, and the ventilation pipe extends to the upper part of the center of the monomer core end. The ventilation pipe is provided with two air ducts, one is a natural ventilation duct, and the other is a fan ventilation duct. A fan is installed at the air outlet.

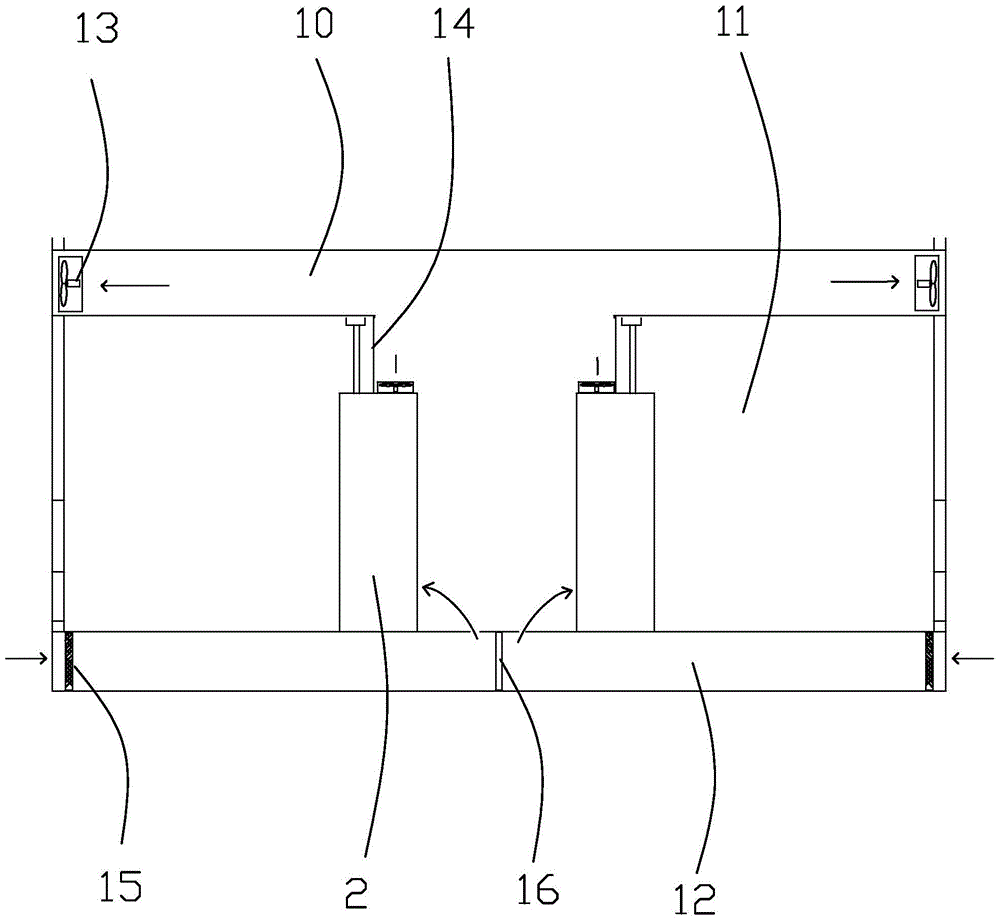

[0047] Such as image 3 As shown, another machine room structure is given. The machine room is separated to form an upper ventilation chamber 10 on the upper part, a lower ven...

example 1

[0068] Example 1: Fault tolerance in refrigeration equipment, ie when one of the refrigeration compressors fails.

[0069] Check whether Y0 and Y1 are normal. If both compressors are normal, the Q value remains unchanged. If Q is 0, Y0 is the main compressor and Y1 is the backup compressor. If Y0 is normal and Y1 is abnormal, set Q to 0 and set Y0 is set as the main compressor, and an alarm signal Y1 is abnormal; if Y1 is normal and Y0 is abnormal, then Q is set to 1, Y1 is set as the main compressor, and an alarm signal Y0 is abnormal is sent to the cluster monitoring cloud. Whether the compressor is normal or not is provided by the pressure switch of the compressor. That is to say, the pressure of the compressor will deviate from the normal value regardless of power failure or leakage. The on-off signal is provided in time. The monitoring system cannot complete the switching action, and another The compressor remains in normal operation.

example 2

[0070] Example 2: When the ambient temperature is less than 35 degrees Celsius

[0071] The temperature control unit acquires an outside temperature of less than or equal to 35 degrees Celsius, and the processing unit analyzes and determines that the start-up temperature of the main compressor remains at a default value of 36 degrees Celsius. When the temperature in the cabinet exceeds 36 degrees Celsius, start the main compressor;

[0072] Before each cycle except the first cycle, the processing unit compares the last P td value, if the value is less than 30% then C td Add 1 to the value, according to the working time T of the main compressor m and standby compressor working time T s The ratio of P sm Displays the load condition of the compressor. When the number of cycles C is greater than 10 and P Ptd More than 30%, start the standby compressor, clear C and P Ptd , restart counting.

[0073] When the temperature control unit obtains that the temperature in the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com