Scanning electron microscope probe current detection device and scanning electron microscope

A technology of a current detection device and a scanning electron microscope, applied in the field of electron optics, can solve the problems of extremely high precision requirements of the sample stage and low current efficiency of the detection probe, and achieve the effect of reducing the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

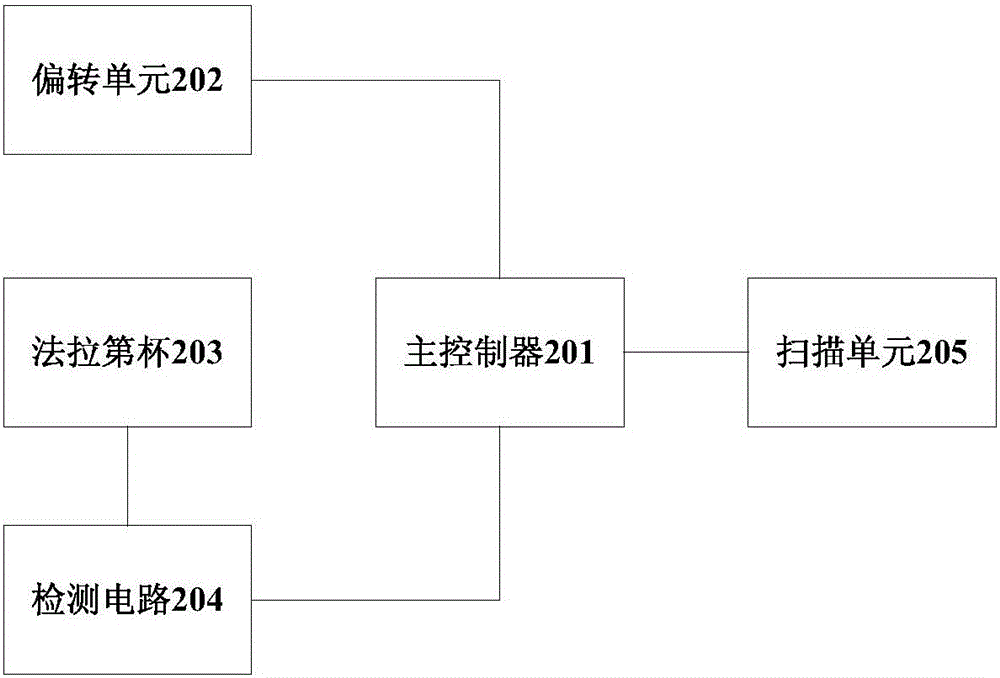

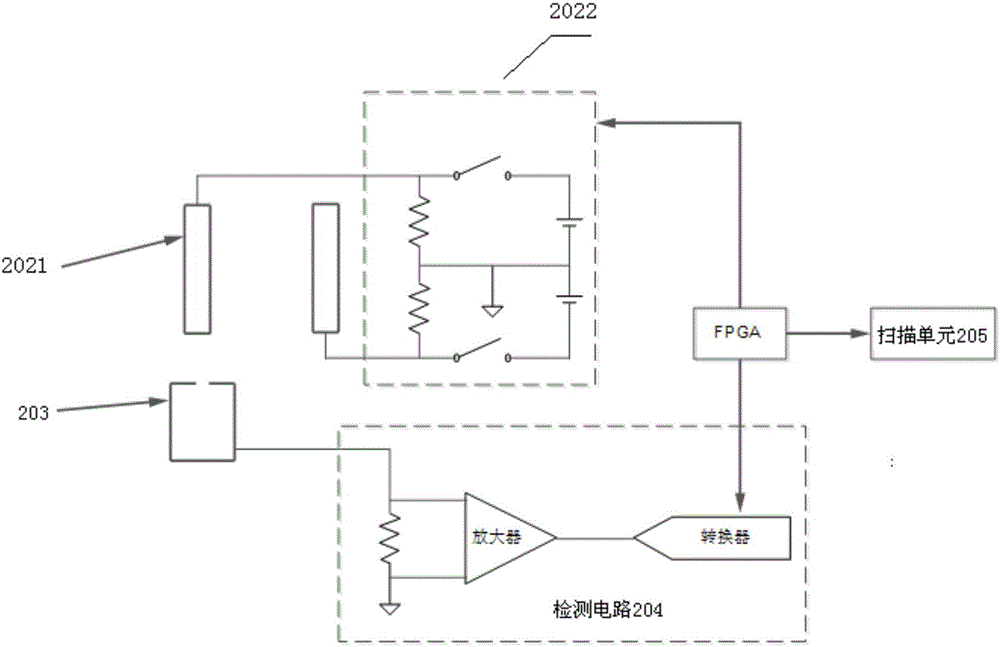

[0040] This embodiment provides a scanning electron microscope probe current detection device, which is arranged in the lens barrel of the scanning electron microscope, such as figure 2 As shown, it includes a main controller 201, a deflection unit 202, a Faraday cup 203 and a detection circuit 204, wherein:

[0041] The deflection unit 202 is arranged between the electron beam generator and the scanning unit, receives the electron beam emitted by the electron beam generator, and controls whether the electron beam is deflected.

[0042] The Faraday cup 203 is arranged in the deflection direction of the electron beam output by the deflection unit, and collects the deflected electron beam.

[0043] The detection circuit 204 is configured to detect the electron beam collected in the Faraday cup 203 .

[0044] The main controller 201 is used to control the working state of the deflection unit 202, the Faraday cup 203 and the scanning unit 205, so as to realize:

[0045] When th...

Embodiment 2

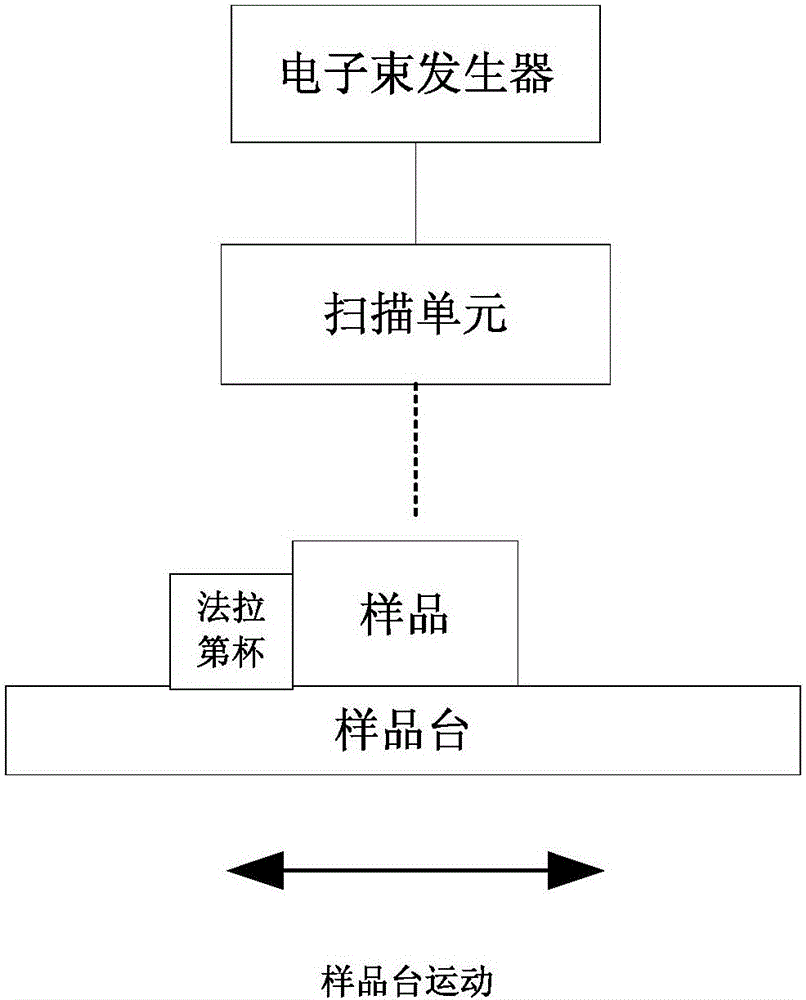

[0050] This embodiment provides a scanning electron microscope, including the scanning electron microscope probe current detection device provided in Embodiment 1, an electron beam generator and a scanning unit. Wherein the electron beam generator is used to generate and emit electron beams, and the scanning unit is used to control the deflection of the electron beams entering it, and perform two-dimensional scanning on the samples on the sample stage. Specifically, such as Figure 4 As shown, the electron beam generator includes an electron gun 401 , a condenser lens 402 and a movable diaphragm 403 . The electron gun 401 generates electron beams, and the condenser lens 402 converges the electron beams generated by the electron gun 401 and transmits them to the movable diaphragm 403 , and the movable diaphragm 403 limits the aperture angle of the electron beams. The scanning unit includes an objective lens 408 and a deflection coil 409. The objective lens 408 converges the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com