Energy-saving battery formation device

A battery formation and energy-saving technology, applied in secondary batteries, electrochemical generators, battery circuit devices, etc., can solve the problems of polluting the power grid, disadvantage, and high energy consumption of resistive formation equipment, so as to save electric energy and improve energy efficiency. Production efficiency, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure and working principle of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments:

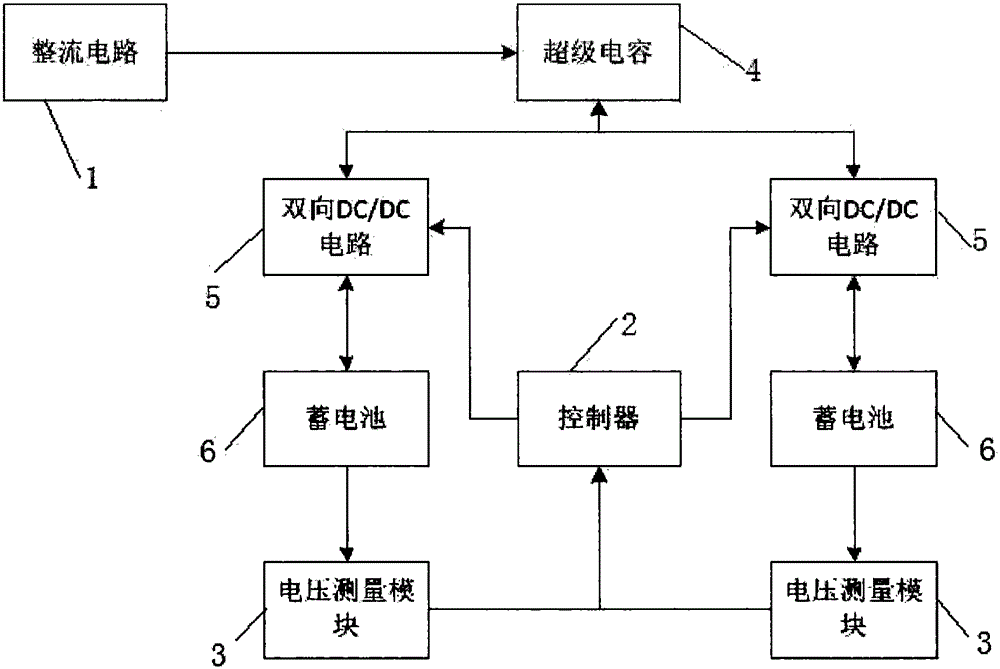

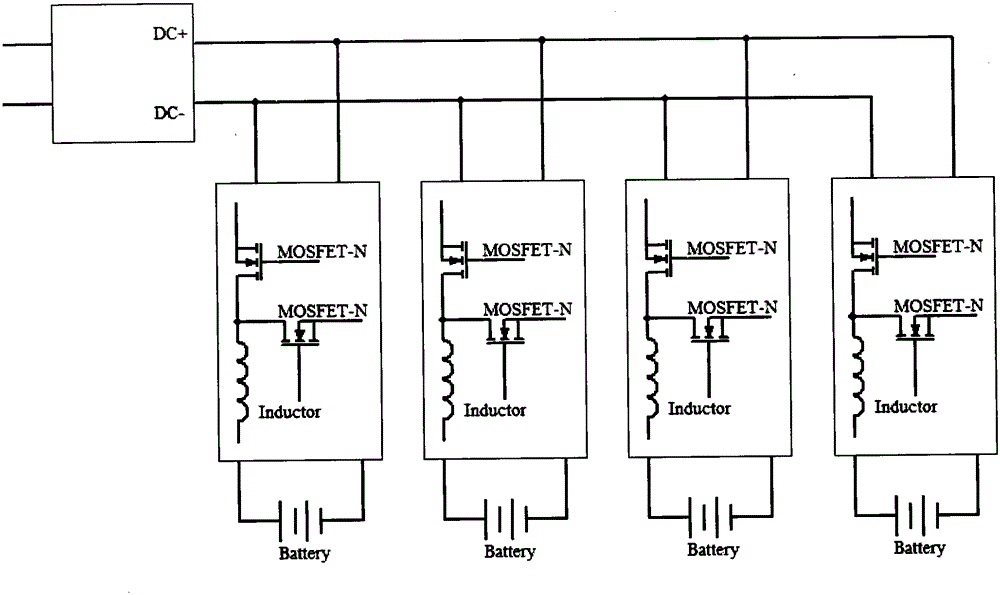

[0021] Such as figure 1 and figure 2 As shown, the present invention provides an energy-saving battery formation device, which includes a rectifier circuit 1, a controller 2, a voltage measurement module 3, a supercapacitor 4, a plurality of bidirectional DC / DC circuits 5, and a storage battery 6. The controller 2 It communicates with the voltage measurement module 3 and multiple bidirectional DC / DC circuits 5 .

[0022] The input end of the rectification circuit 1 is connected to an AC interface, and after the AC is rectified and filtered, a stable DC is formed and output to a supercapacitor and a plurality of bidirectional DC / DC circuits;

[0023] The voltage measuring module 3 is used to collect the voltage signal of the storage battery, and communicates with the controller, and transmits the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com