powder machine

A rack and powder-spraying technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of affecting the health of the powder-sprinkler, the production process is time-consuming and laborious, and the lack of automatic powdering equipment can save manpower. Cost, improve production quality, less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

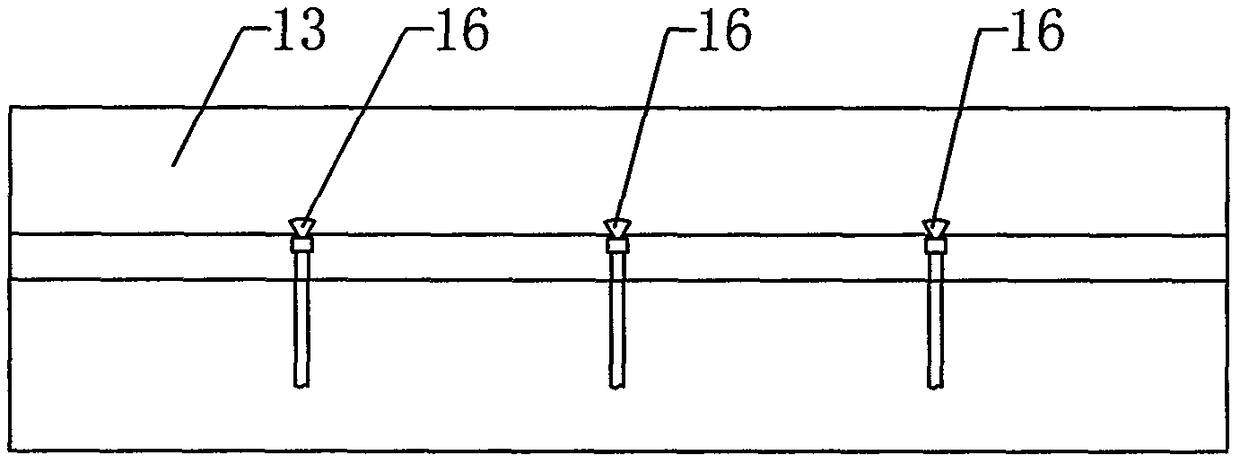

[0024] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, the powder feeding machine includes a frame 1, and the frame 1 is provided with a conveying system;

[0025] Transmission system comprises multiple guide rollers such as guide roller 2, guide roller 19, guide roller 10, guide roller 15, guide roller 20, guide roller 23, guide roller 2, guide roller 19 and guide roller 20 are positioned at frame 1 top, and guide roller The roller 23 is located in the middle of the frame 1, and the guide roller 10 and the guide roller 15 are located in the lower part of the frame 1;

[0026] The frame 1 is also provided with a glue dispensing device and a powder spreading device matched with the conveying system;

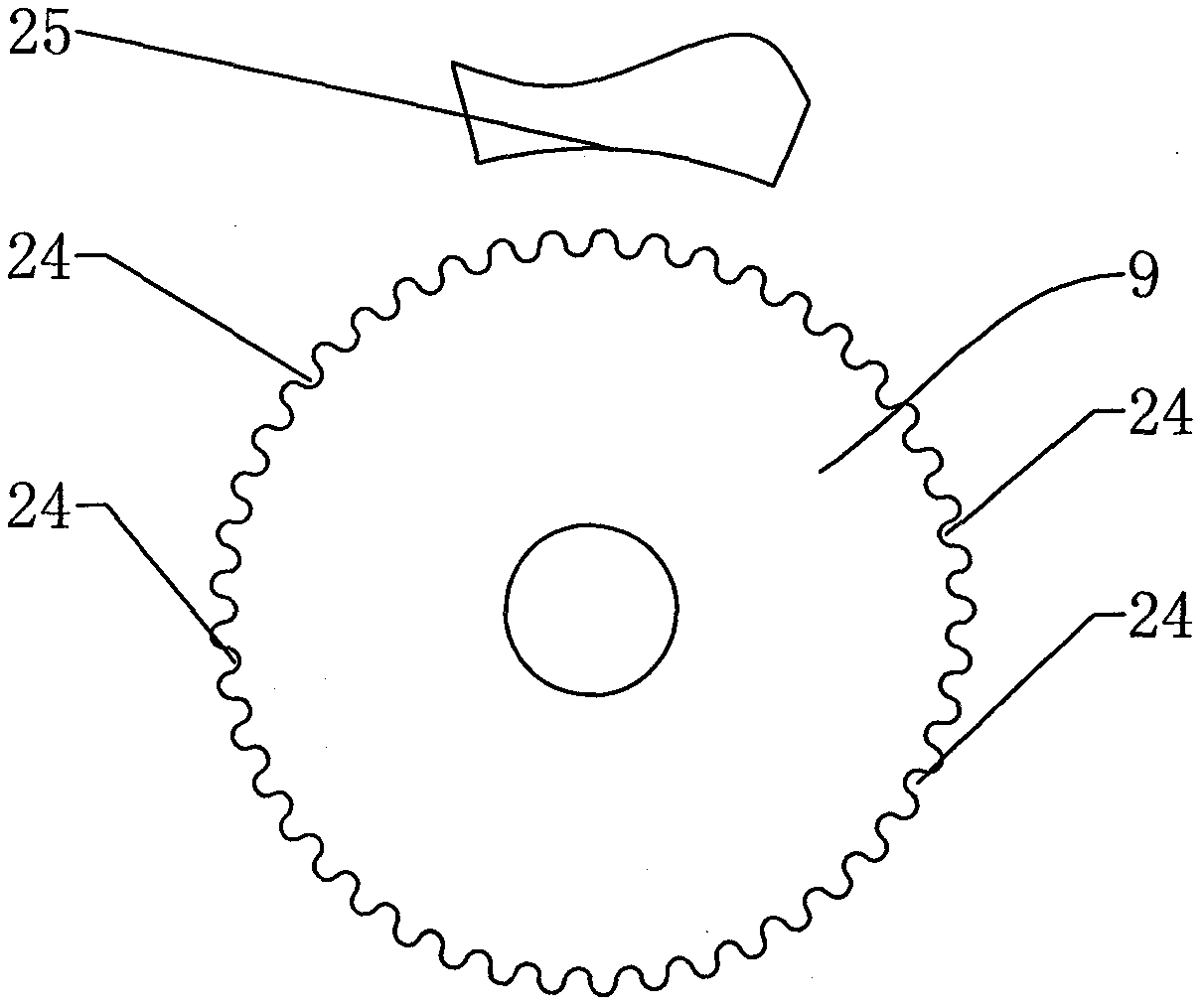

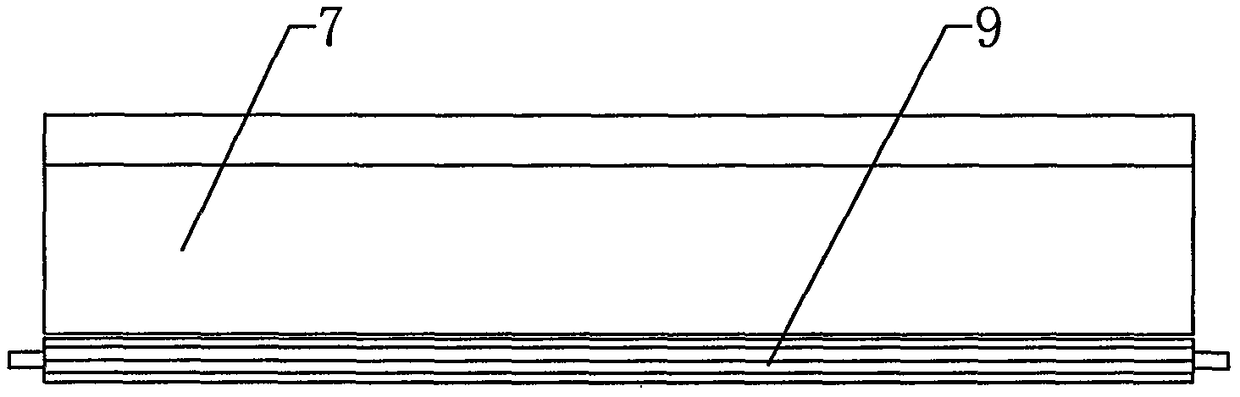

[0027] The powder spreading device includes a hopper 7, a rotating shaft 9 and a driving device that controls the rotation of the rotating shaft 9. The driving device includes a third motor 8 and a transmission mechanism. The output shaft of the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com