Nickel-base superalloy welding wire for 700 DEG C-above ultra-supercritical coal power generation equipment

A technology for nickel-based superalloys and power generation equipment, applied in welding equipment, metal processing equipment, welding media, etc., can solve the problem that the structure and performance of Inconel740H joints cannot meet the index requirements of ultra-supercritical coal-fired power generation equipment, the impact of welding joint performance, The aging strengthening effect is reduced and other problems, so as to achieve the effects of excellent welding process performance, excellent welding seam forming performance, good high temperature strength and long-lasting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is specifically described below through examples.

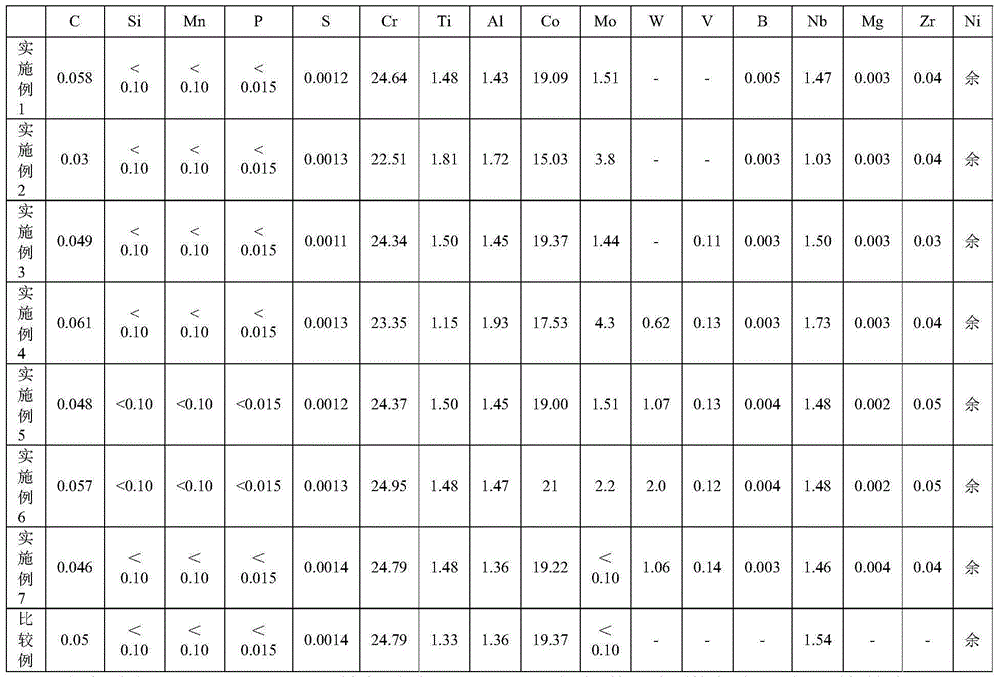

[0021] Nickel-based superalloy welding wire for ultra-supercritical coal-fired power generation equipment above 700 °C, including C, Cr, Co, Mo, W, Nb, Ti, Al, B, Zr, Mg, V, Ni and unavoidable impurity elements, See Table 1 for the weight percentages of each component and the weight percentages of S, P, Si and Mn in impurities obtained through actual measurement.

[0022] Table 1 shows the comparison between the test results of the chemical composition of the alloys in the examples and the chemical composition of the actual welding wire materials developed abroad.

[0023] Table 1 The measured results of the chemical composition of the alloys of Examples 1-7 and comparative examples

[0024]

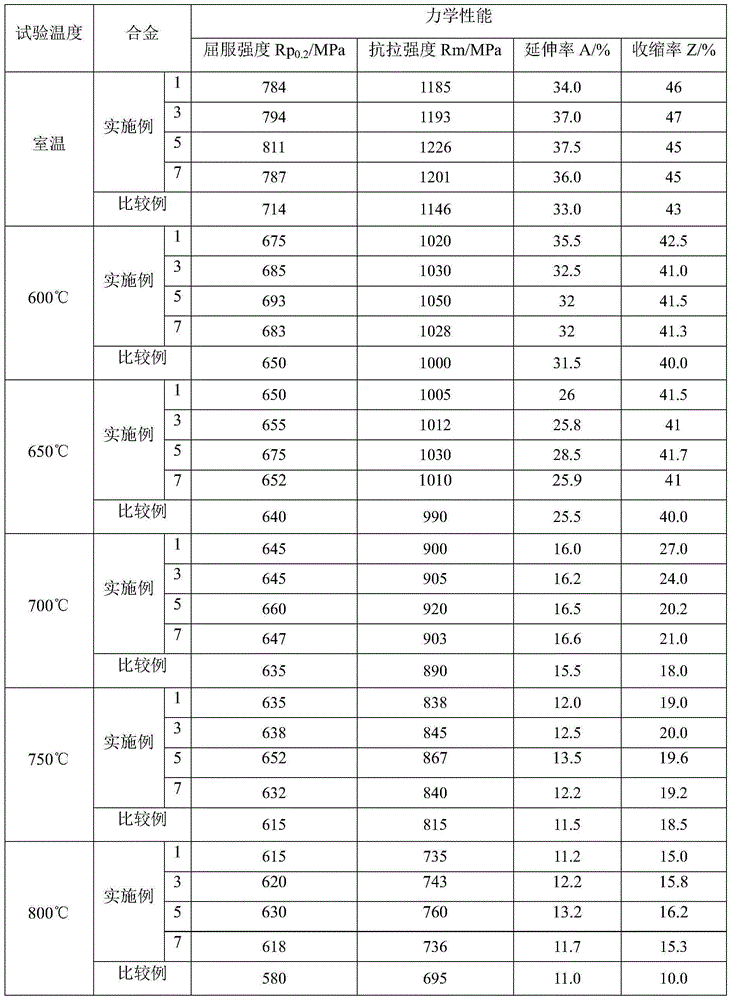

[0025]The nickel-based superalloy used for ultra-supercritical coal-fired power generation equipment above 700°C in Examples 1, 3, 5, 7 and Comparative Example was processed int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com