Water curtain argon integrated welding protection device in high frequency longitudinally welded pipe

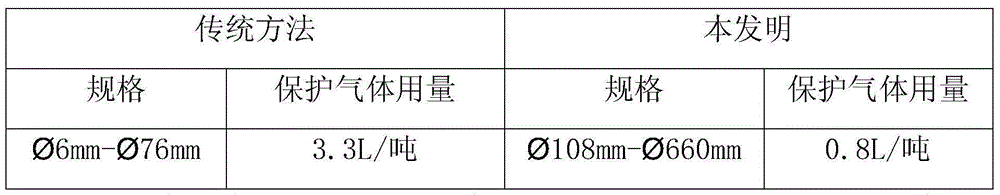

A technology for straight seam welded pipes and water curtains, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effects of reducing production costs, improving utilization, and widening the span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

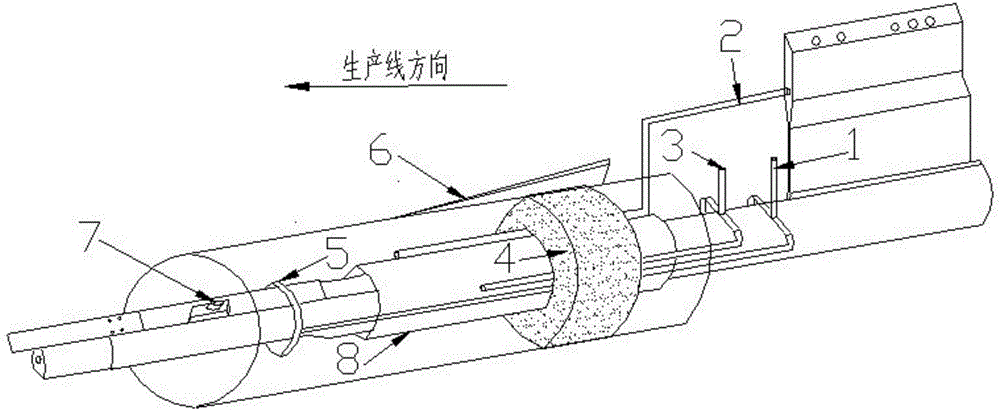

[0015] The structure of the high-frequency longitudinal welded pipe inner water curtain argon comprehensive welding protection device of the present invention is described in conjunction with the accompanying drawings.

[0016] The structure design idea of the high-frequency straight seam welded pipe inner water curtain argon comprehensive welding protection device of the present invention is based on the inner wall of the steel pipe, the first water curtain protection device, the second high-temperature cotton protection device and the outer surface of the inner burr mandrel to form a In the semi-closed argon chamber, when the argon gas is filled into the cavity at an appropriate flow rate, the argon gas will slowly overflow from the welding opening at the upper end because the specific gravity of argon gas is greater than that of air, and the welding joint will be heated to a semi-molten state. The material is isolated from the air to protect the weld.

[0017] The high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com