Twin-screw extruder used for preparing 105 DEG C polyvinyl chloride cable material

A twin-screw extruder and polyvinyl chloride cable technology, which is applied in the field of twin-screw extruders, can solve the problems of unsatisfactory screw thread distribution structure, easy damage to the drive bearing bearing structure, increased maintenance frequency and cost, and the like. Excellent mixing performance, convenient disassembly, assembly, maintenance and replacement, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

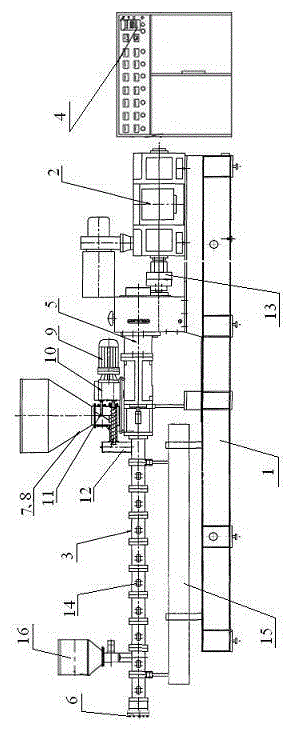

[0018] Such as figure 1 Shown is a twin-screw extruder for preparing 105°C polyvinyl chloride cable material, including a frame 1, a main motor 2 arranged on the frame, a barrel 3 and an electrical control cabinet 4 for the whole machine. One end of the machine barrel is provided with a high-power transmission box 5, the output shaft of the main motor 2 is connected with the high-power transmission box 5 through a coupling 13, and the output shaft of the high-power transmission box 5 is connected with the twin screws. The high-power transmission box 5 adopts a parallel three-axis structure, which integrates deceleration and torque distribution. At the same time, it adopts oil-immersed lubrication and multi-point forced lubrication system, and establishes a low oil level and overpressure alarm system to remind operators in time. Change the oil to ensure the long-term and efficient operation of the transmission box. The main motor 2 adopts an AC motor with a rated power of 0.75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com