Optical microfluidics chip for fixing monoclonal antibody modified layer based on nanometer seal

A technology of microfluidic chips and nano-stamps, applied in printing, material inspection products, stamping, etc., can solve the problem that the detection method is not convenient enough, the non-quantitative gold standard test strips are not suitable for on-site detection, bedside detection, and gold standard test strips Insufficient quantitative detection and other problems, to avoid perfusion sample injection operations, reduce edge effects, and avoid sample reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

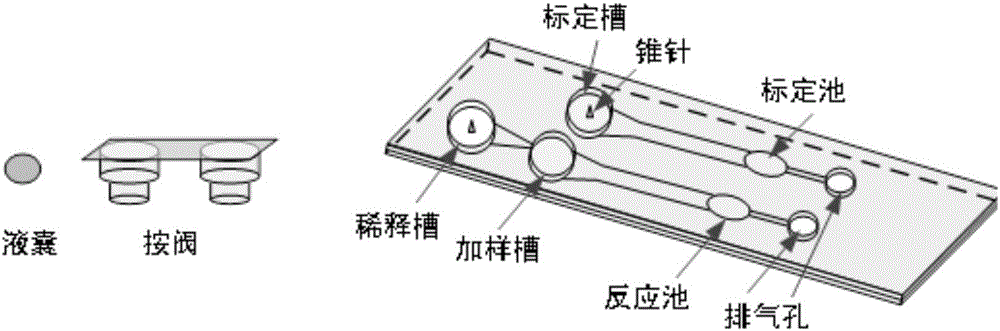

[0058] figure 1 A schematic structural view of an optical microfluidic chip based on a nanostamp-immobilized monoclonal antibody modified layer according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the optical microfluidic chip includes a lower substrate, an upper cover plate, a calibration tank, a dilution tank, a sampling tank, a channel, a calibration tank, a reaction tank, an exhaust hole, a press valve, a liquid storage bag, and an awl needle. The microfluidic immune chip is used for rapid and sensitive detection of extremely low concentration substances such as protein macromolecules in blood samples, urine samples, saliva and other biological samples.

[0059] Wherein, the microfluidic immune chip based on magnetic particles is an integrated chip prepared based on MEMS technology, magnetic particle enrichment and separation technology, immune technology and F-TIR optical detection principle.

[0060] Among them, the upper cove...

Embodiment 2

[0066] figure 2 A schematic structural view of an optical microfluidic chip based on a nano-stamp immobilized monoclonal antibody modified layer according to the second embodiment of the present invention is shown. Such as figure 2 As shown, the optical microfluidic chip includes a lower substrate, an upper cover plate, a calibration tank, a sample loading tank, a channel, a calibration pool, a reaction pool, an exhaust hole, a press valve, a liquid storage bag and an awl needle. Compared with Example 1, the optical microfluidic chip in this example does not have a dilution tank.

[0067] Both the lower base plate and the upper cover plate are made of transparent plastic plates, which are prepared by hot pressing molding technology, and at the same time, calibration grooves, sample filling grooves, sample feeding vents, and calibration vents are formed on the upper cover plate.

[0068] Channels, calibration pools, and reaction pools are prepared with ultra-thin double-sid...

Embodiment 3

[0072] image 3 It is a schematic structural diagram of an optical microfluidic chip based on a nano-stamp immobilized monoclonal antibody modified layer according to the third embodiment of the present invention, as shown in image 3 As shown, the optical microfluidic chip includes: a lower substrate, an upper cover plate, a liquid storage tank, a sample loading tank, a channel, a reaction pool, a comparison pool, an exhaust hole, a press valve, a liquid storage bag and an awl needle.

[0073] The lower substrate is made of transparent plastic plate, which is prepared by hot pressing molding technology. The upper cover plate is made of hydrophilic single-sided adhesive material, and laser engraving technology is used to form liquid storage tanks, sample feeding tanks, channels, and reaction channels on the hydrophilic single-sided adhesive material. Pools, contrast pools and vents.

[0074] The channel, contrast pool and reaction pool are prepared with ultra-thin double-side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com