Self-propelled work platform moving across medial strip barrier of motorway

A technology for median strips and expressways, applied to roads, roads, road safety devices, etc., can solve problems such as limited installation space, small contact area, and concentrated force, and achieve enhanced anti-derailment capabilities, increased contact area, and good performance. Orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

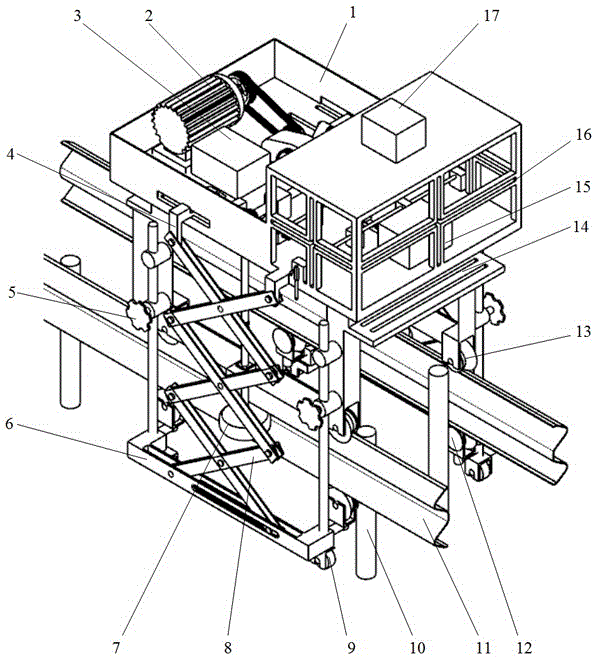

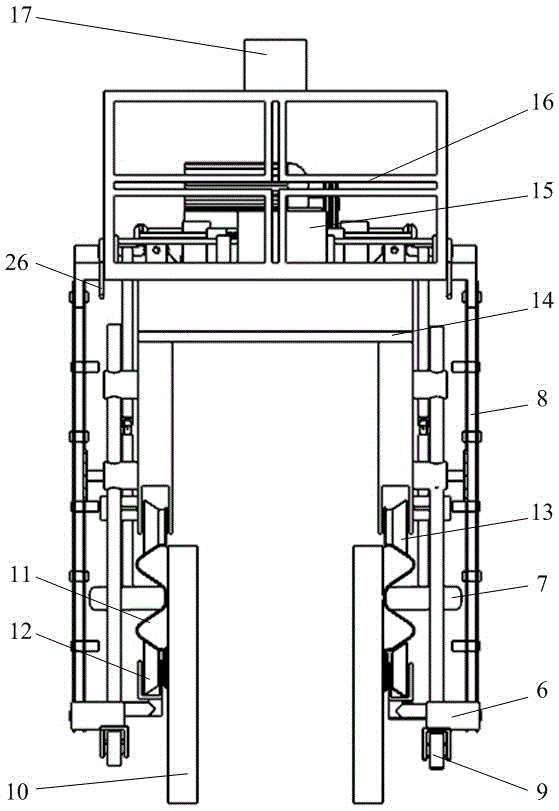

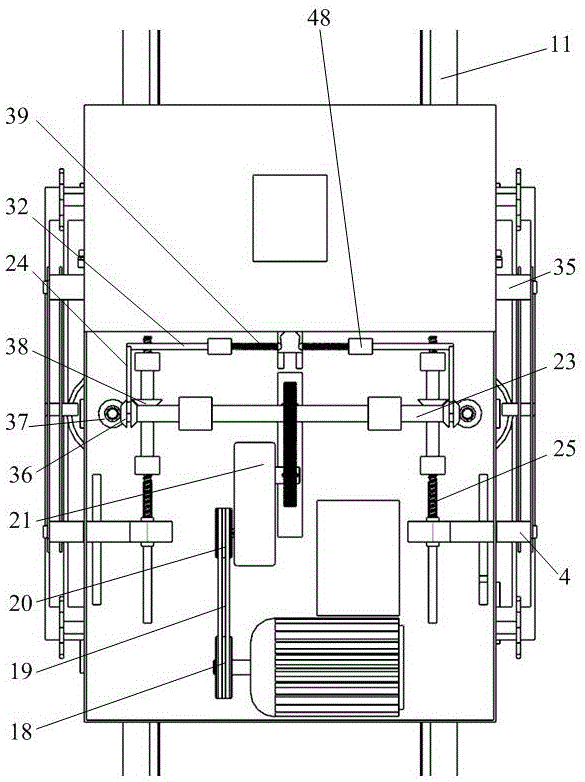

[0024] refer to Figure 1~Figure 4 , the self-propelled work platform that straddles the guardrail of the central divider of the expressway includes a car body 1, a hurdle walking device, a ground wheel lifting device, a power transmission device, and a machine tool carrying device, wherein the car body 1 is driven by two pairs of upper profiling wheels 13 1. Two pairs of lower profiling wheels 12 and a pair of profiling drive wheels 7 make their whole ride on two parallel wave beam guardrails 11 of the expressway median, and the width of the car body 1 is the same as that of the two parallel wave beam guardrails 11. match the width between them.

[0025] refer to Figure 1~Figure 10 The hurdle walking device includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com