Method for modifying biotite through pillared intercalation

A technology of biotite and biotite powder, which is applied in the fields of chemistry and metallurgy, can solve the problems of high-temperature roasting activation of too many doping agents, low economic benefits, etc., and achieve low cost and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

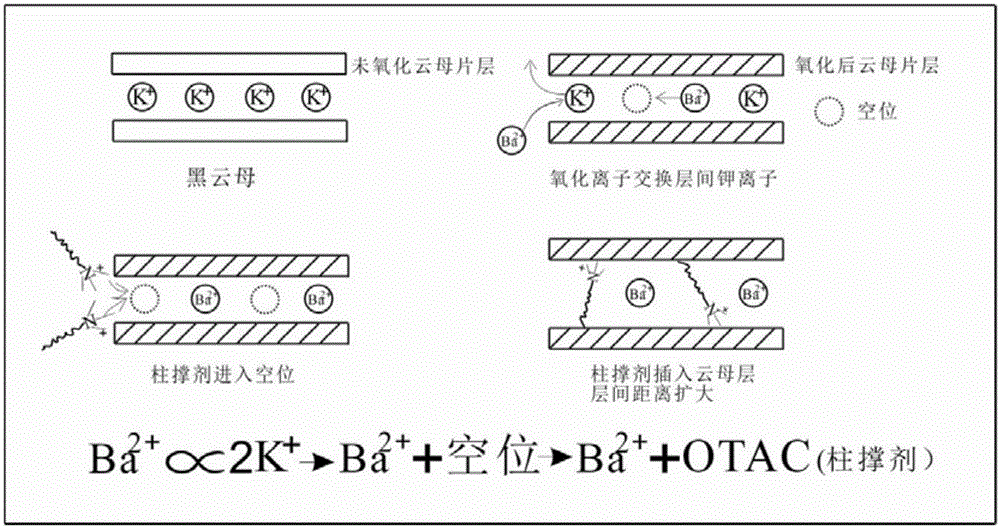

Method used

Image

Examples

Embodiment 1

[0019] (1) Cross 200 mesh sieves after the biotite ore is pulverized with a ball mill;

[0020] (2) The biotite after crushing is mixed with the aqueous solution of barium nitrate with a concentration of 0.25mol / L. The mass volume ratio of the aqueous solution of biotite and barium nitrate is 1:20g / mL, and the hydrochloric acid solution with a concentration of 10wt% is used to adjust the mixture to 5, add 0.5CEC octadecyltrimethylammonium chloride, place it in a constant temperature water bath at 50°C and stir for 3h, analyze the solid insoluble matter by X-ray diffraction (XRD), and analyze the layer of biotite The distance between them was extended to 1.733nm.

Embodiment 2

[0022] (1) Cross 200 mesh sieves after the biotite ore is pulverized with a ball mill;

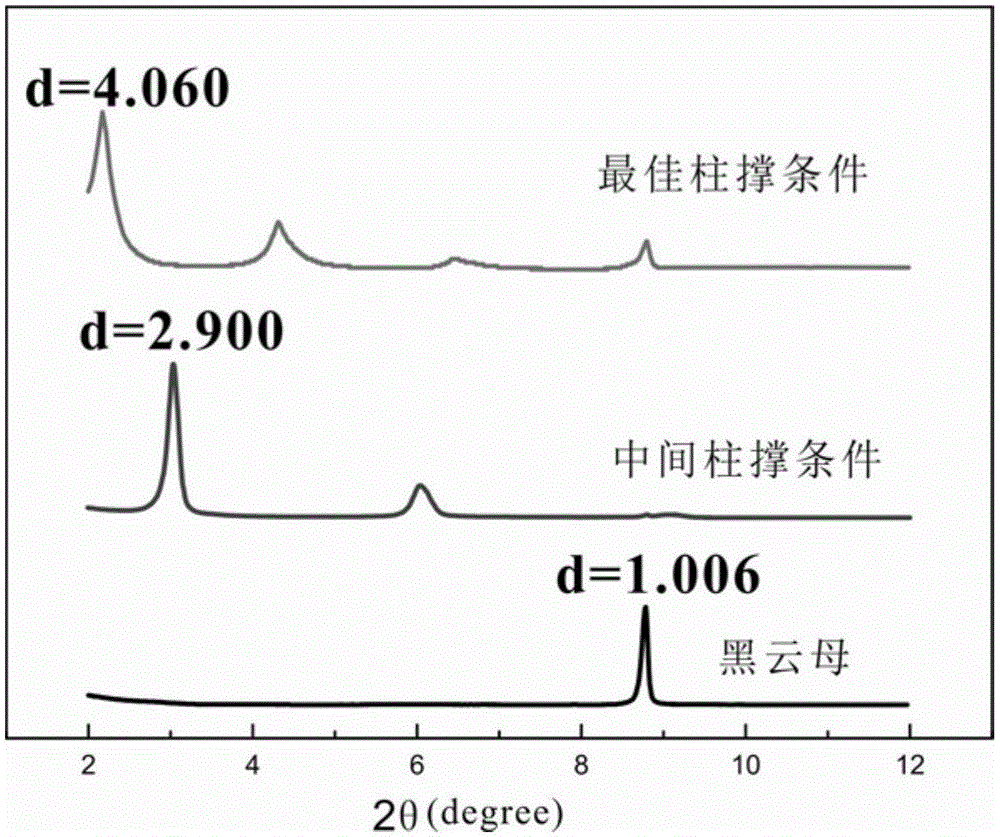

[0023] (2) The broken biotite is mixed with the aqueous solution of barium nitrate with a concentration of 1.00mol / L, the mass volume ratio of the aqueous solution of biotite and barium nitrate is 1:30g / mL, and the hydrochloric acid solution with a concentration of 10wt% is used to adjust the mixture to 3, add 0.6CEC octadecyltrimethylammonium chloride, place in a constant temperature water bath at 70°C and stir for 4 hours, analyze the solid insoluble matter by X-ray diffraction (XRD), and analyze the layer of biotite The distance between them has been extended to 2.900nm.

Embodiment 3

[0025] (1) Cross 200 mesh sieves after the biotite ore is pulverized with a ball mill;

[0026] (2) The biotite after the crushing is mixed with the aqueous solution of barium nitrate with a concentration of 1.75mol / L. The mass volume ratio of the aqueous solution of biotite and barium nitrate is 1:50g / mL, and the hydrochloric acid solution with a concentration of 10wt% is used to adjust the mixture to 2, add 1.0CEC octadecyltrimethylammonium chloride, place in a constant temperature water bath at 80°C and stir for 5 hours, analyze the solid insolubles by X-ray diffraction (XRD), and analyze the layer of biotite The distance between them was extended to 4.060nm.

[0027] figure 2 It is the XRD figure of embodiment 2 and implementation case 3 after the modification of biotite compared with biotite. It can be seen from the figure that the interlayer spacing of biotite has been significantly expanded after adding the pillaring agent, and the pillaring effect will gradually inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com