Fluorophosphate optical glass

A technology of optical glass and fluorophosphate, applied in optics, optical components, instruments, etc., can solve problems such as insufficient chemical stability, thermal stability, processing performance, easy crystallization and streaks, poor thermal stability of glass, etc. Achieve good chemical stability, excellent thermal stability, excellent special dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

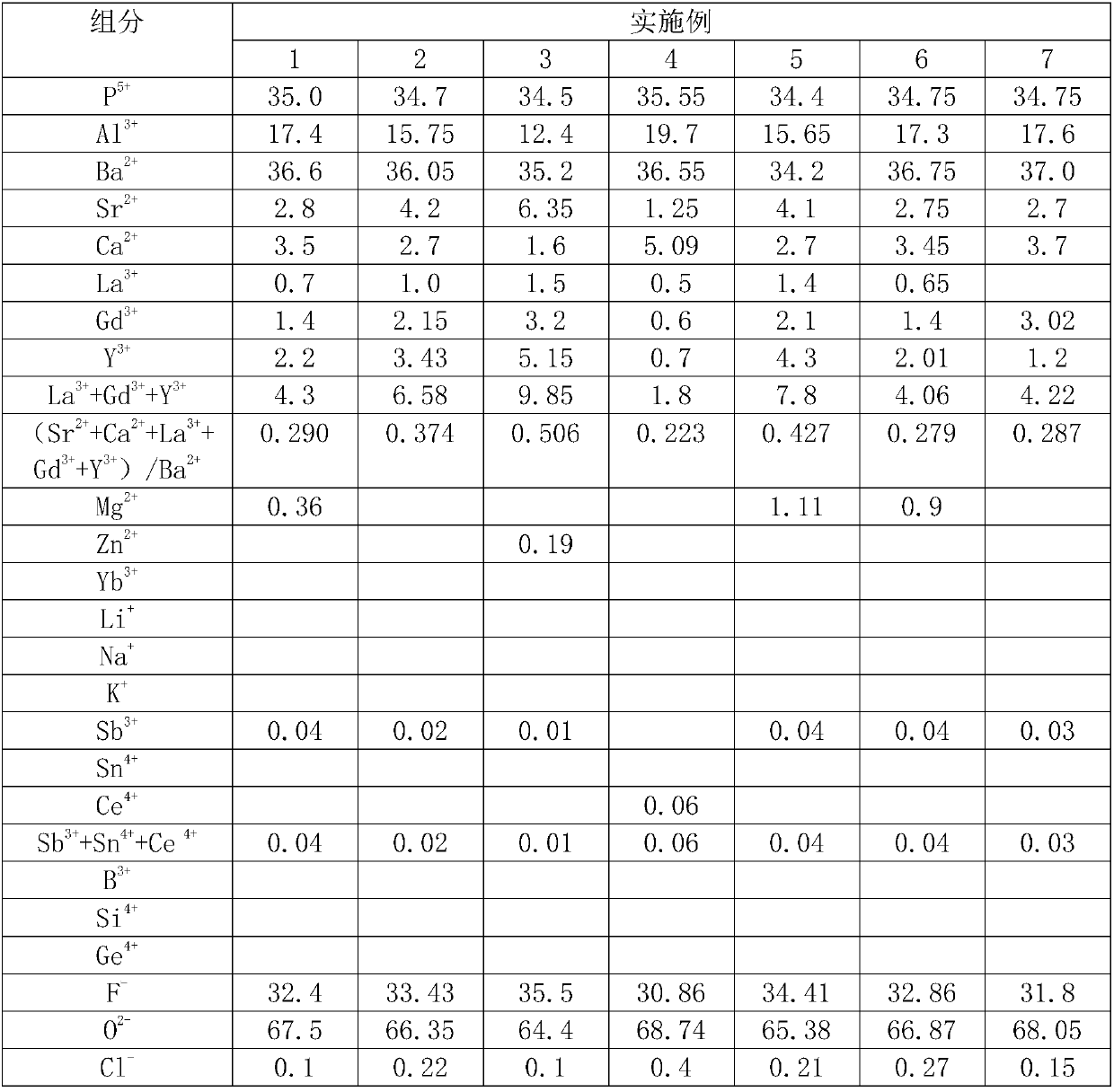

[0024] The role of each composition and the scope-limiting role of the present invention are explained below.

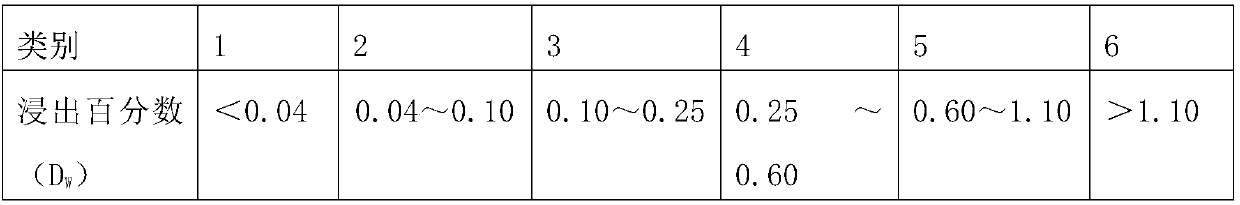

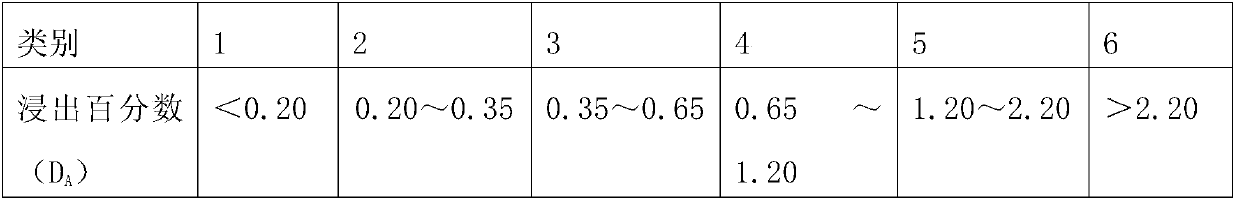

[0025] It should be noted that in this specification, each cationic component and the total content of cationic components are represented by "cation percentage", and each anion component and the total content of anion components are represented by "anion percentage". "Cation percentage" refers to the percentage of a certain cationic component in the total cationic content, and "anion percentage" refers to the percentage of a certain anionic component in the total anionic content. The aforementioned contents are molar contents.

[0026] P 5+ It is a composition constituting the glass network. When the content is less than 30%, the stability of the glass is poor, and when the content exceeds 40%, it is difficult to obtain the high refractive index required by the present invention. Considering from the required optical performance and chemical stability of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com