Concrete mud resisting agent based on counter-insert layer design and preparing method thereof

A technology of concrete and anti-mud agent, which is applied in the field of concrete anti-mud agent and preparation based on reverse intercalation design, which can solve the problems of polycarboxylate superplasticizer dosage fluctuation, increase construction cost, increase and so on, so as to improve the initial The effect of slump, strong adaptability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the content of the present invention, the following examples are specifically cited to describe the present invention in further detail. The examples are given by way of illustration, but in no way limit the content of the invention. The protection scope of the present invention shall be determined by the description of the claims.

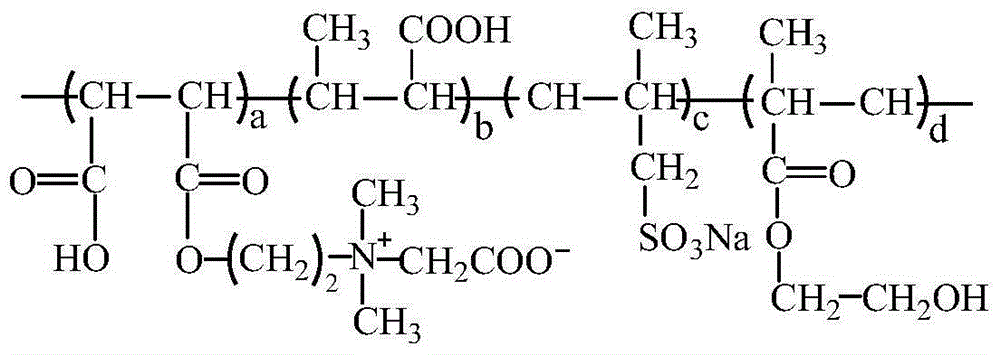

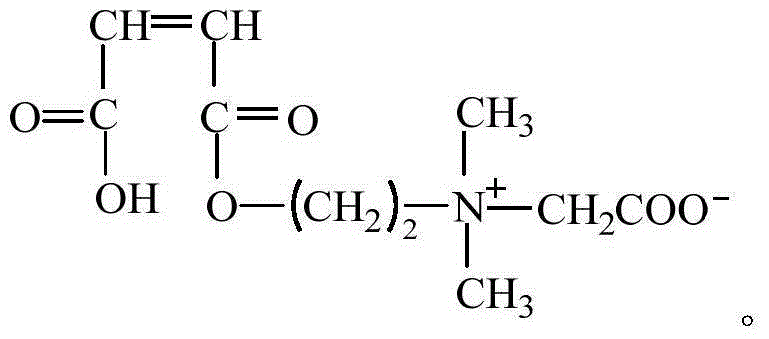

[0033] A concrete mud-resistant agent based on reverse intercalation design, characterized in that its molecular weight is 8000-13500, and its general structural formula is:

[0034]

[0035] Wherein, a=20-30, b=5-10, c=10-15, d=10-20.

[0036] Embodiment matching is as shown in table 1, and concrete implementation process is as follows:

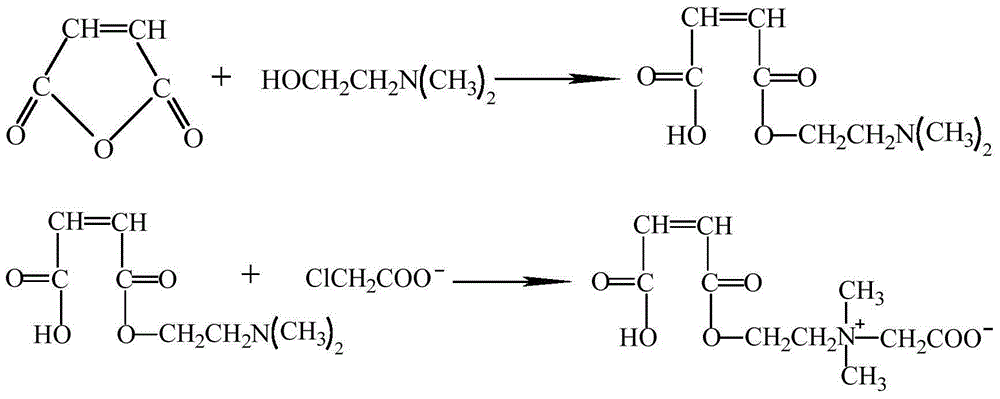

[0037] 1) Stir and dissolve the small molecule monomer, 2-butenoic acid, sodium methacrylate, and hydroxyethyl methacrylate, keep the temperature at 70-75°C to obtain a uniform solution, then add an oxidant, and stir to obtain a uniform solution;

[0038] 2) Add reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com