Meat carcass continuous pyrolysis carbonization method

A technology of pyrolysis carbonization and carcasses, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of incomplete pyrolysis treatment, large loss of pyrolysis chamber temperature, waste of pyrolysis chamber temperature, etc., and achieves Continuity and orderliness, labor cost savings, and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

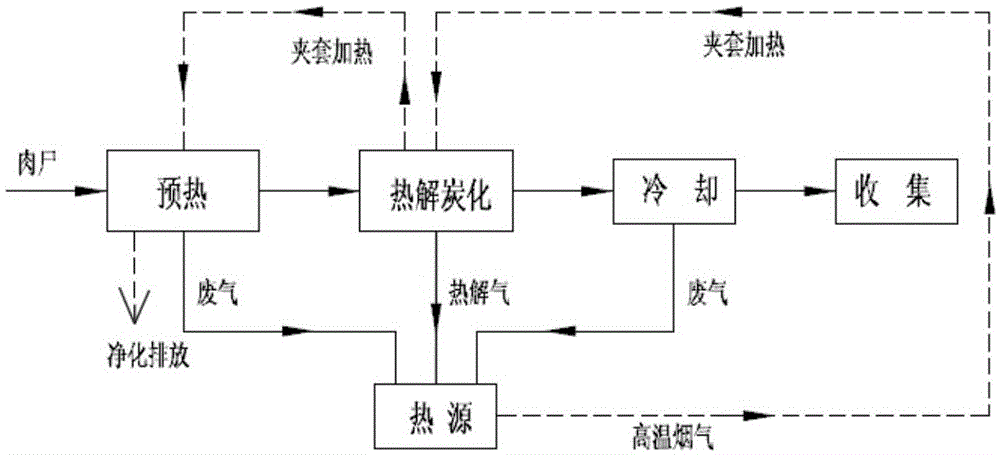

[0060] figure 1 It is the process flow diagram of the continuous pyrolysis carbonization method for embodiment one meat corpse; as figure 1 As shown, a method for continuous pyrolysis and carbonization of meat corpses, including preheating, pyrolysis and carbonization, cooling and pyrolysis gas recycling, is characterized in that:

[0061] (a) Preheating part: place the material basket 5 with a length of 1 in which the carcasses are placed in the preheating chamber 1 with oxygen insulation, normal pressure and 100-300°C, and carry out jacketed pretreatment to ensure that the temperature in the preheating chamber 1 In an oxygen barrier state;

[0062] (b) Pyrolysis and carbonization part: After pretreatment, the material basket 5 is continuously pushed into the carbonization chamber 2 with a working length of L to keep the carbonization chamber 2 in a sealed and oxygen-isolated state, and the heat source heats the carbonization chamber 2 in a jacketed manner, so that The meat...

Embodiment 2

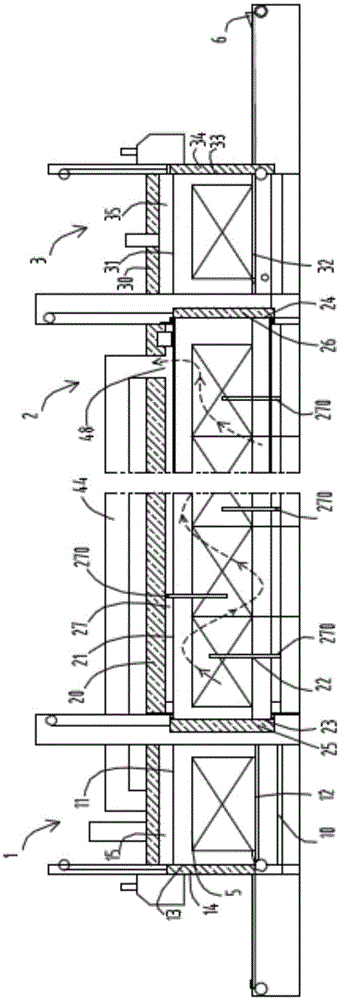

[0073] figure 2 It is a schematic diagram of the overall structure of the continuous pyrolysis and carbonization device for meat corpses in Embodiment 2; figure 2 As shown, a continuous pyrolysis and carbonization device for meat corpses includes a preheating chamber 1, a carbonization chamber 2, a cooling chamber 3, a pyrolysis gas recycling unit 4, and a material basket 5. The material basket 5 is used to place meat corpses. The preheating chamber 1 and the cooling chamber 3 are placed at both ends of the carbonization chamber 2 and communicate with the carbonization chamber 2 respectively;

[0074] The preheating chamber 1 includes a first furnace body 10, a first furnace 11 and a first guide rail 12, and the first feeding end 13 of the preheating chamber 1 is provided with a first furnace door 14 that can be lifted and lowered to play a sealing role; Form the first air duct 15 between the first furnace 11 outer wall and the inner wall of the first furnace body 10; Push...

Embodiment 3

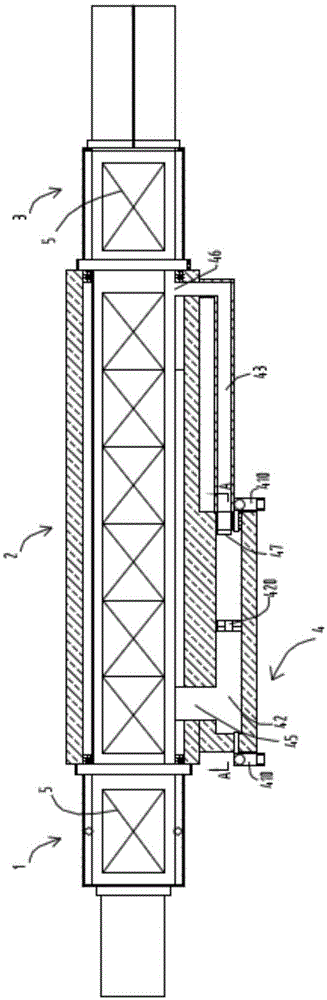

[0101] Figure 4 It is a top view of the third continuous pyrolysis carbonization device for meat carcass in the embodiment of the present invention; Figure 7 It is a partial cross-sectional view of the combustion chamber A-A of Embodiment 3 of the present invention. Such as Figure 4 As shown, in this embodiment, the preheating chamber 1 and the cooling chamber 3 can accommodate two material baskets, and both can accommodate the same number of material baskets. Such as Figure 7 As shown, in this embodiment, the combustion chamber 42 is provided with three gas barriers 430, the gas barriers 430 divide the combustion chamber 42 into four spaces, and the height of the gas barriers 430 is lower than that of the combustion chamber 42 The gas circulates through the gap 440 between the gas blocking wall 430 and the inner wall of the combustion chamber 42 . Other structures and connection relationships of this embodiment are basically the same as those of Embodiment 2, and need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com