High-temperature coal tar washing oil fraction combination processing method

A high-temperature coal tar and combined processing technology, which is applied in the chemical and petroleum fields, can solve problems affecting conversion rate and yield, and achieve the effect of reducing fractionation temperature and lowering the possibility of coke formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

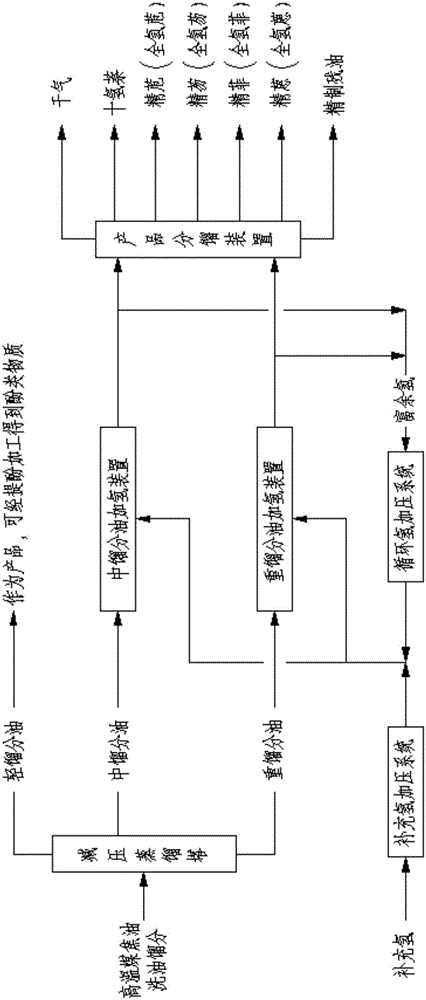

[0036] A method for combined processing of high-temperature coal tar washing oil fractions, the processing steps are as follows:

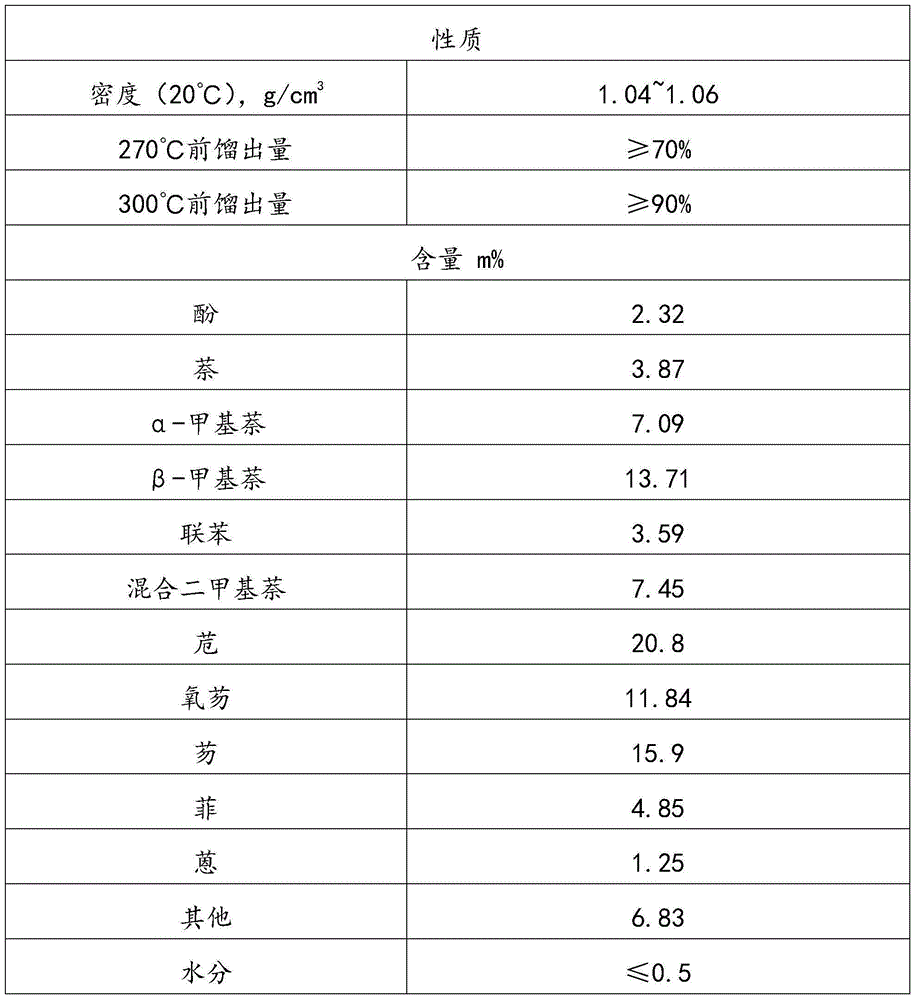

[0037] (a) High-temperature coal tar wash oil fraction (property is example with the content of Table 1) first enters vacuum distillation tower and carries out fractionation, obtains light distillate oil, middle distillate oil and heavy distillate oil; The final boiling point of described light distillate oil is 230 °C, the final boiling point of middle distillate oil is 250-270 °C, and the final boiling point of heavy distillate oil is 300-315 °C;

[0038] (b) The light distillate oil obtained in step (a) is used as a product, which can be processed to obtain phenolic substances through phenol extraction;

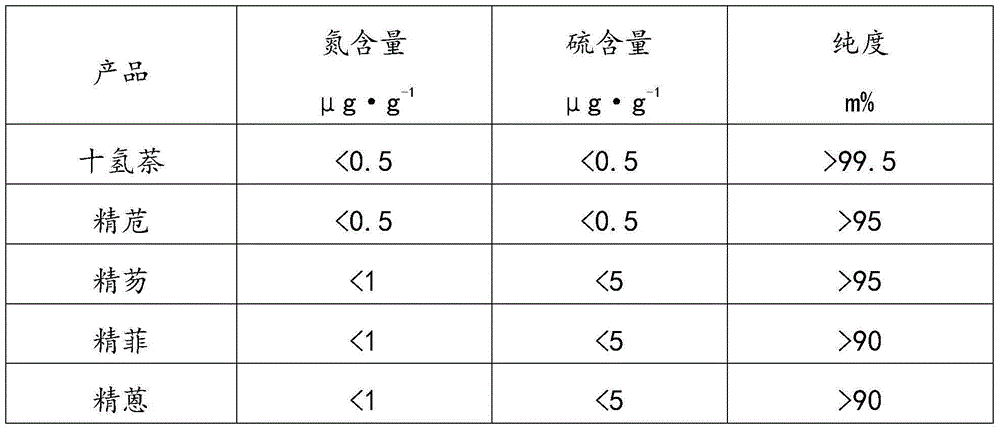

[0039] (c) The middle distillate oil obtained in step (a) is mixed with excess hydrogen and then enters a middle distillate oil hydrogenation unit, and is contacted with a hydrogenation catalyst in the presence of hydrogen to carry out a hydrog...

Embodiment 2

[0048] A method for combined processing of high-temperature coal tar washing oil fractions, the processing steps are as follows:

[0049] (a) High-temperature coal tar wash oil fraction (property is example with the content of Table 1) first enters vacuum distillation tower and carries out fractionation, obtains light distillate oil, middle distillate oil and heavy distillate oil; The final boiling point of described light distillate oil is 230 °C, the final boiling point of middle distillate oil is 250-270 °C, and the final boiling point of heavy distillate oil is 300-315 °C;

[0050] (b) The light distillate oil obtained in step (a) is used as a product, which can be processed to obtain phenolic substances through phenol extraction;

[0051] (c) The middle distillate oil obtained in step (a) is mixed with excess hydrogen and then enters a middle distillate oil hydrogenation unit, and is contacted with a hydrogenation catalyst in the presence of hydrogen to carry out a hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com