Heat conduction oil online regeneration composite additive

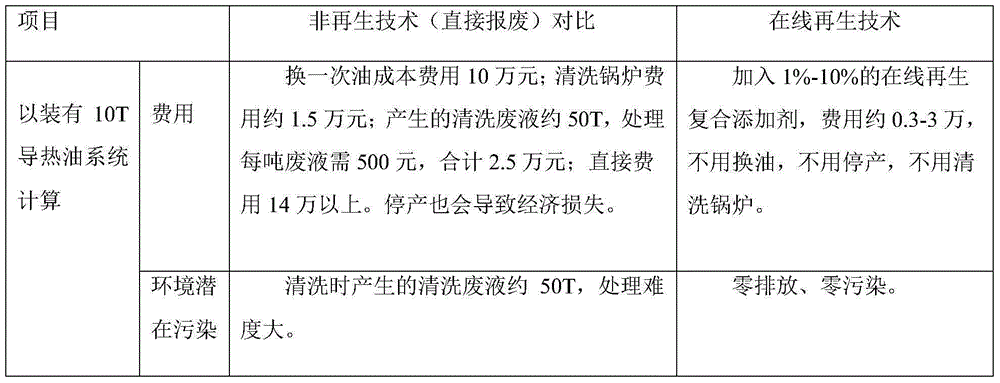

A compound additive and heat transfer oil technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of wasting resources, quality degradation and affecting use, and achieve the effects of prolonging service life, stable and reliable quality, and improving heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

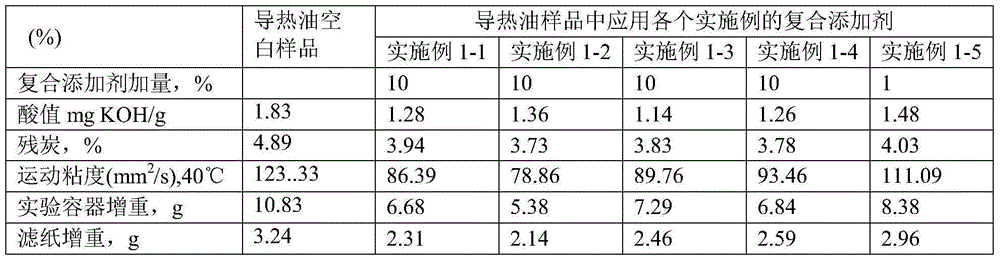

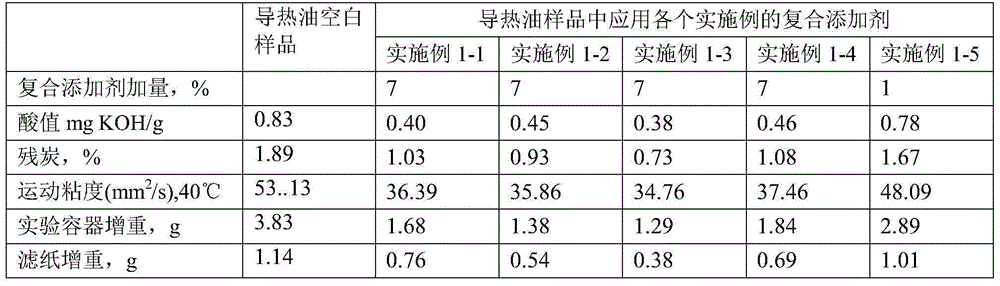

Examples

Embodiment 1

[0076] Heat transfer oil on-line regeneration composite additive 1000Kg, including: amine antioxidant: L57 40Kg, T516 40Kg, phenolic antioxidant 2246 40Kg, L135 20Kg, T501 20Kg, detergent T106 30Kg, T107 30Kg, dispersant T154 20Kg, T155 40Kg, the balance is base oil. Among them, the distillation range of the base oil is 300-320°C, and the kinematic viscosity is 32mm 2 / s, density 0.94g / cm 3 .

Embodiment 2

[0078] Heat transfer oil on-line regeneration composite additive 1000Kg, including: amine antioxidant: T534 30Kg, T531 30Kg, phenolic antioxidant L135 30Kg, T501 30Kg, detergent T122 40Kg, T107 40Kg, dispersant T154 30Kg, T155 30Kg, The balance is base oil. Among them, the distillation range of the base oil is 280-300°C, and the kinematic viscosity is 35mm 2 / s, density 0.92g / cm 3 .

Embodiment 3

[0080] Take 760Kg of base oil, heat it to 120°C for dehydration, and keep it for about 1 hour until all the water is removed. Add solid additives T501 20Kg, T516 20Kg, T531 20Kg, 2246 20Kg and stir to dissolve; cool down to 80°C, add T534 20Kg, L135 20Kg, T106 20Kg, T107 20Kg, T122 20Kg, T155 30Kg, T154 30Kg, and stir for 60 minutes barreled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com