Washing machine

A washing machine and machine body technology, applied in the field of washing machines, can solve the problems of large space occupation, inconvenient maintenance, troublesome cleaning of filter components, etc., and achieve the effects of reducing air pressure loss, convenient installation/disassembly, and convenient separation of water and electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

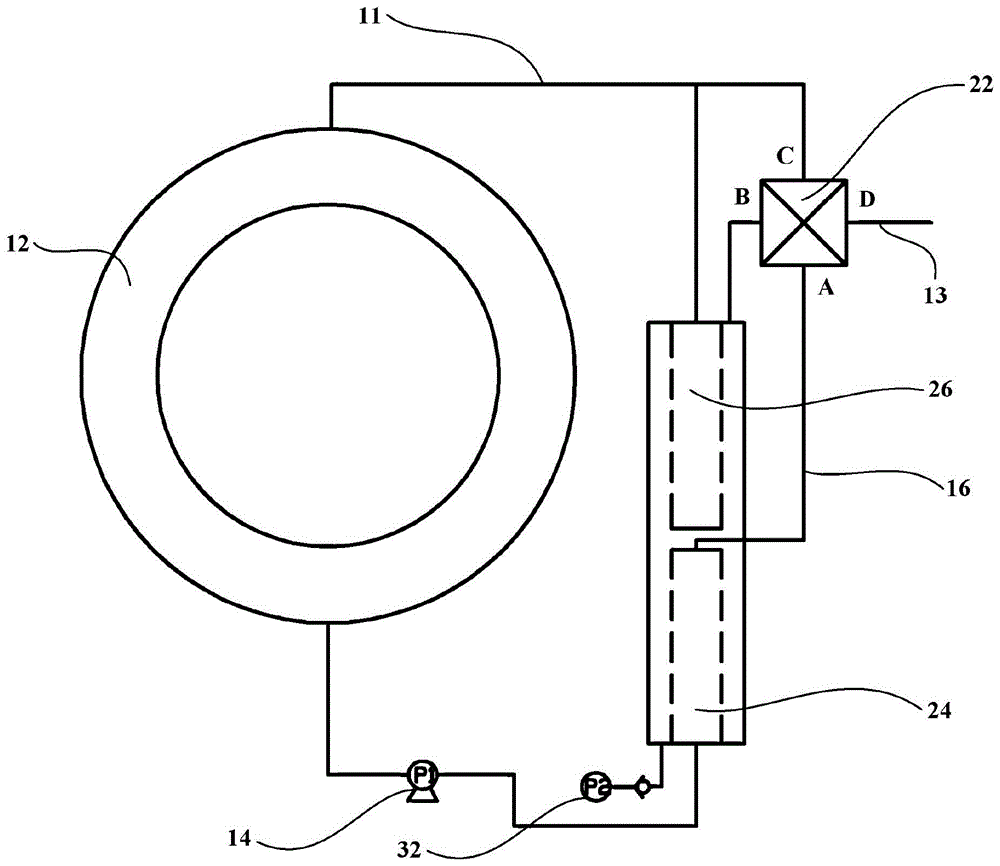

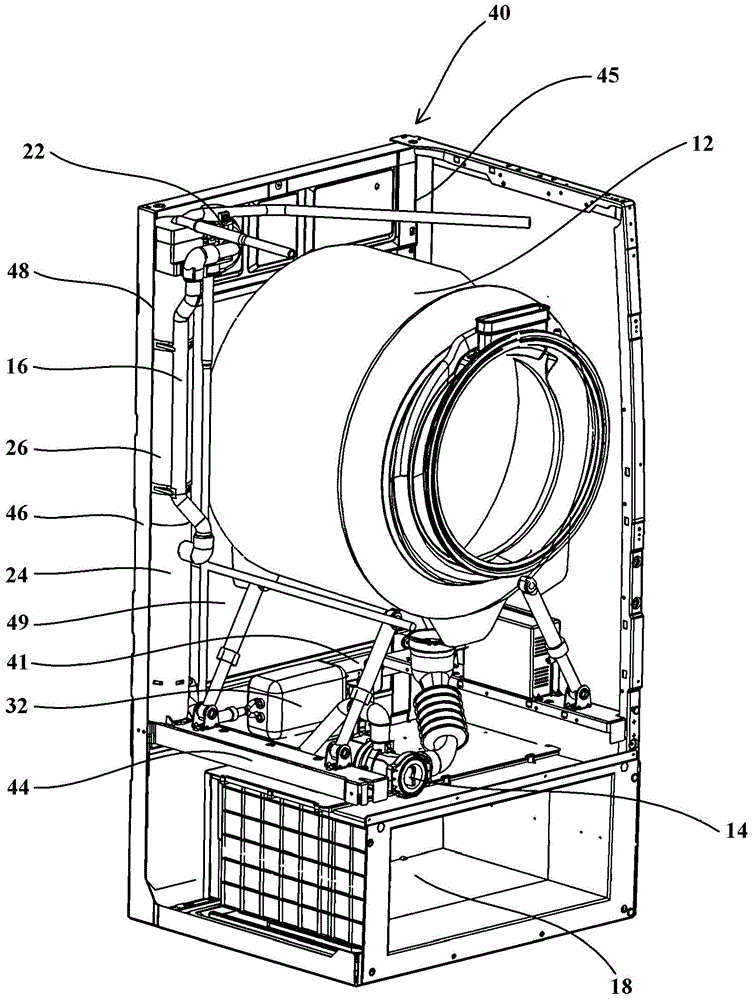

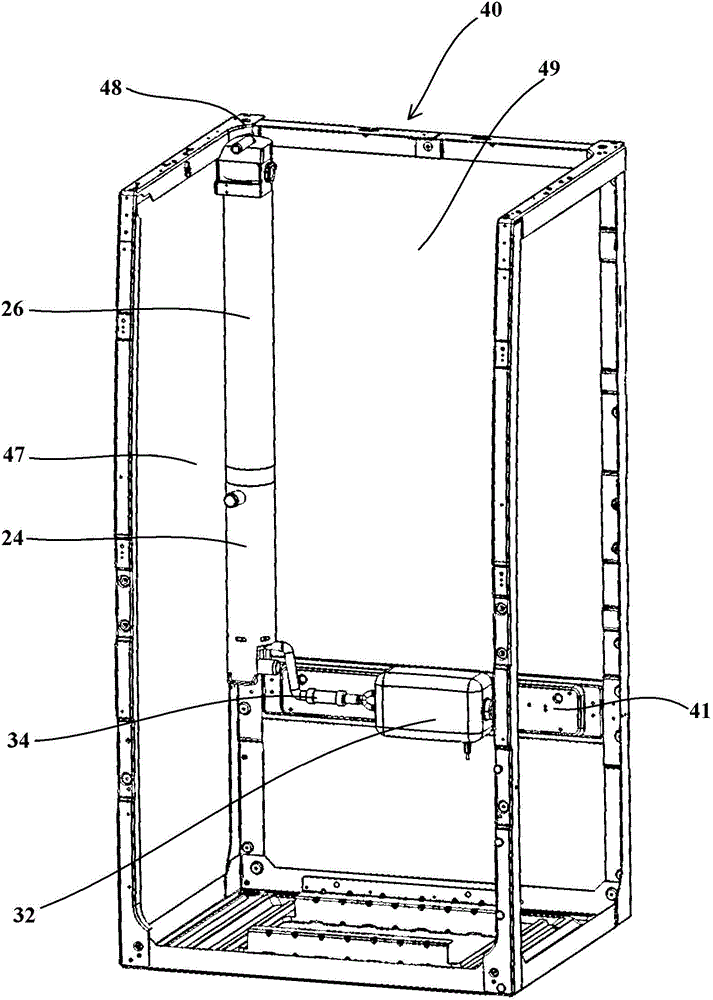

[0041] figure 1 is a schematic schematic diagram of a washing machine according to an embodiment of the present invention. The washing machine may include a washing tub 12, a drain pump 14, and a filter assembly. The washing tub 12 is generally composed of an outer tub and an inner tub that can rotate in the outer tub. The bottom of the washing tub 12 is provided with a drain port, and the drain port communicates with the filter assembly via a drain pump 14 through a pipeline. According to needs, for example, in the washing program or rinsing program of the washing machine, the water in the washing tub 12 can be pumped out, transported to the filter assembly for filtering, and then circulated back to the washing tub 12 for reuse.

[0042] The filter assembly of the embodiment of the present invention uses sieving as the separation principle, which can effectively reduce the residual lint of clothes, and can effectively remove particles, colloids, bacteria, microorganisms and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com