Yizheng fiber short fiber dyed imitation cotton

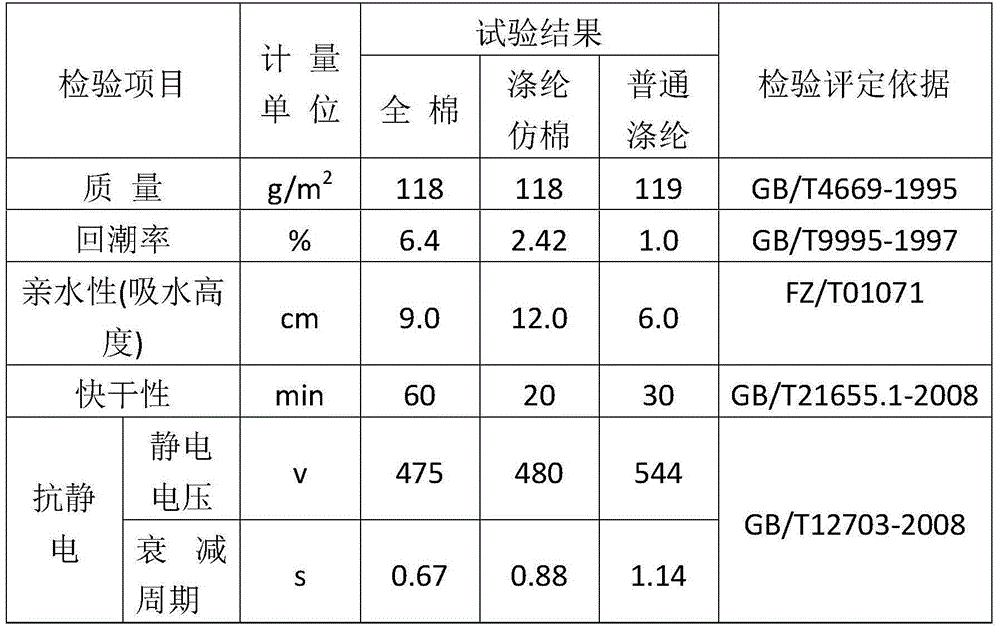

A staple fiber and Yilun technology, which is applied in the field of Yilun staple fiber dyeing and imitation cotton, can solve the problems of easy ash absorption and pilling, high static electricity of polyester and cotton, and poor water absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to achieve the stated purpose, the Yilun staple fiber dyeing imitation cotton of the present invention uses Yilun gray cloth as a raw material, and is characterized in that it comprises the following steps:

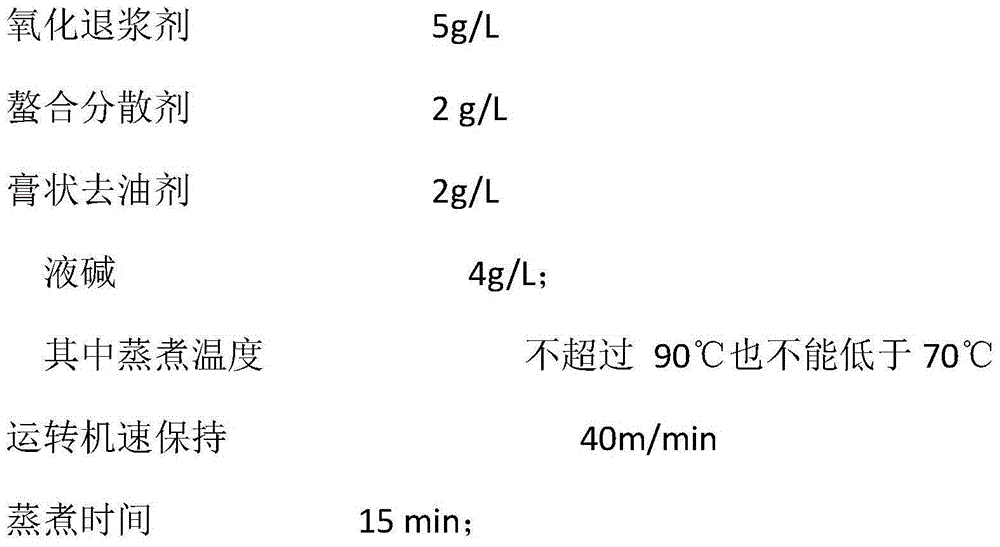

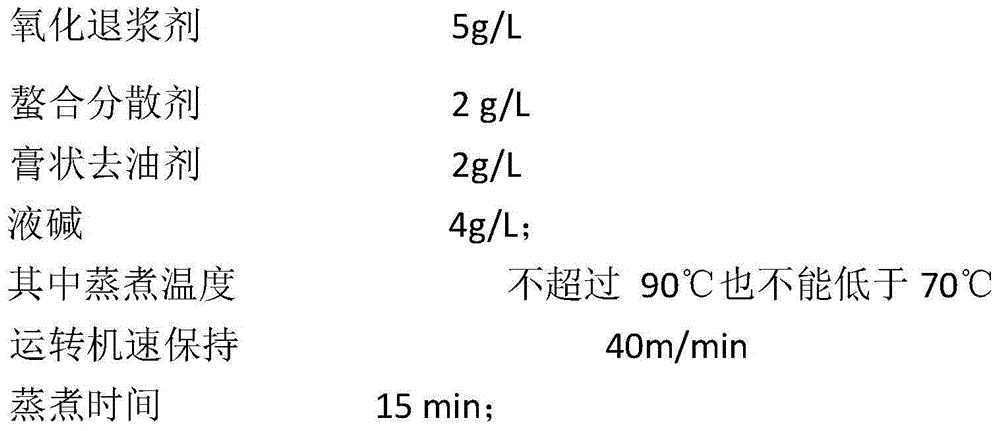

[0020] Step 1: Cooking, use the open-width continuous desizing washing machine to cook the gray cloth, so that the size, weaving oil, and impurities on the gray cloth are decomposed, shed, and removed from the cloth surface during the cooking process. During the cooking process, add:

[0021]

[0022] Step 2: Dyeing treatment, within 60°C, add dyeing agent for dyeing, the dyeing heating rate is set within 1.5°C / min, when it reaches 60°C, keep it warm for 5-10min, and continue to set the heating rate at 1.0°C / min. 100-120°C heat preservation as stipulated in the process, the heat preservation time is controlled at 30-60 minutes according to the requirements of dyeing depth, and the cooling rate should be reduced to below 60°C at 1.5-2.0°C / min after dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com