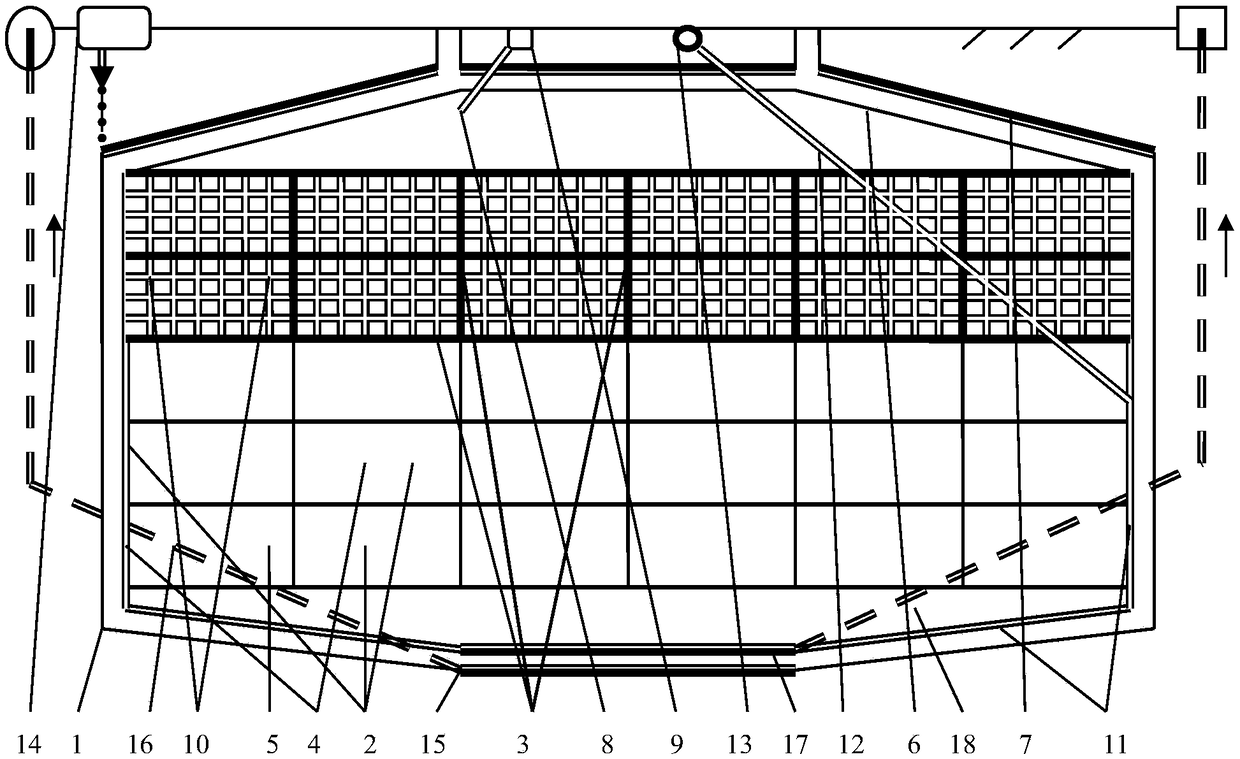

Needle-barrel bonded plastic film connection interface siding underground granary

A technology for connecting interfaces and plastic films, applied in protection devices, underwater structures, infrastructure engineering, etc., can solve problems such as water seepage and humidity of walls, and achieve the effect of suppressing cold storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0064] The granary in Example 3 is circular, but the underground granary of the present invention is not limited to a structure with a circular cross section.

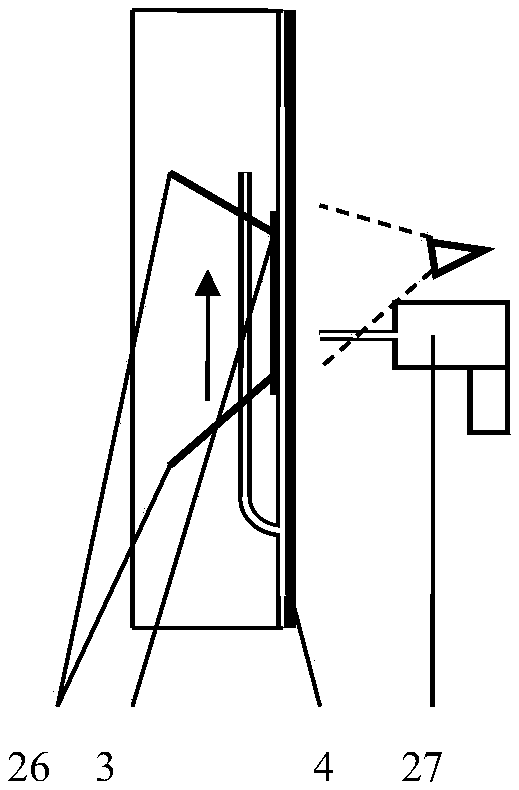

[0065] Figure 5 and 6 A fourth embodiment of the present invention is collectively given.

[0066] Figure 5 and 6 In the process, some soil is dug out below the bottom of the silo 39 in advance, and the outer ring rotary cutting tool 50 is able to enter the installation position. Install strut 51 and annular guide rail 52 and install outer ring rotary cutting tool 50 on the installation interface provided in advance at the bottom of cylindrical warehouse 39, including an outer ring rotary cutting tool screw mandrel composed of fixed plate 53, movable plate 54 and screw mandrel 55 The adjustment mechanism, the outer ring rotary cutting tool screw adjustment mechanism is connected with the ring guide rail 52 through a rotating pair mechanism. By adjusting the relative positions of the fixed plate 53 and the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com