High-efficiency direct drive type pumping unit with single movable pulley and single fixed pulley

A direct drive pumping unit technology, which is applied in the fields of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of transmission system impact, hidden danger of equipment safety, and impact on life, and achieve the need to reduce the torque of the motor , workover and maintenance are convenient, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

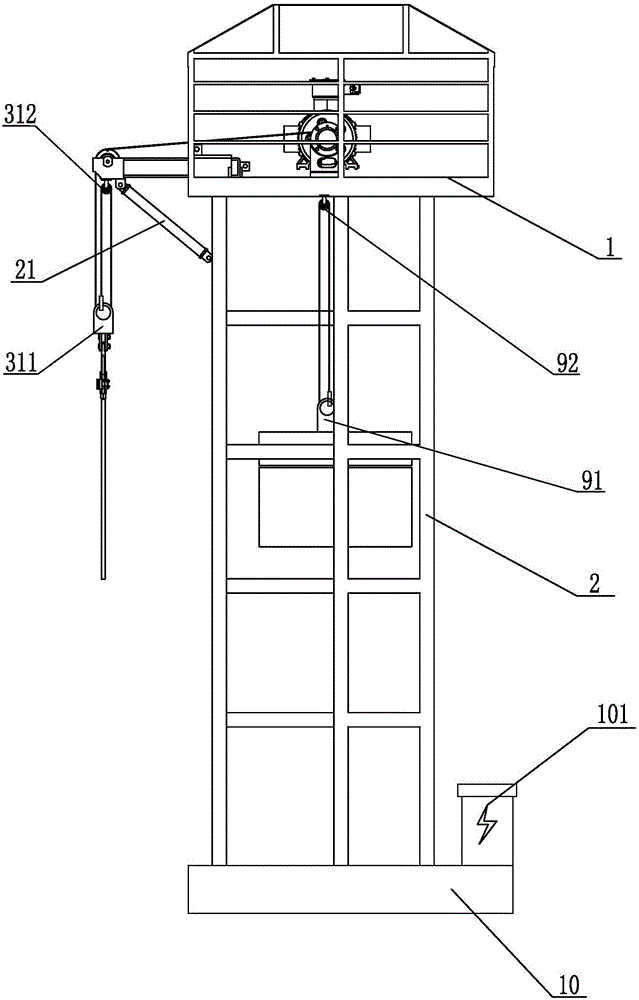

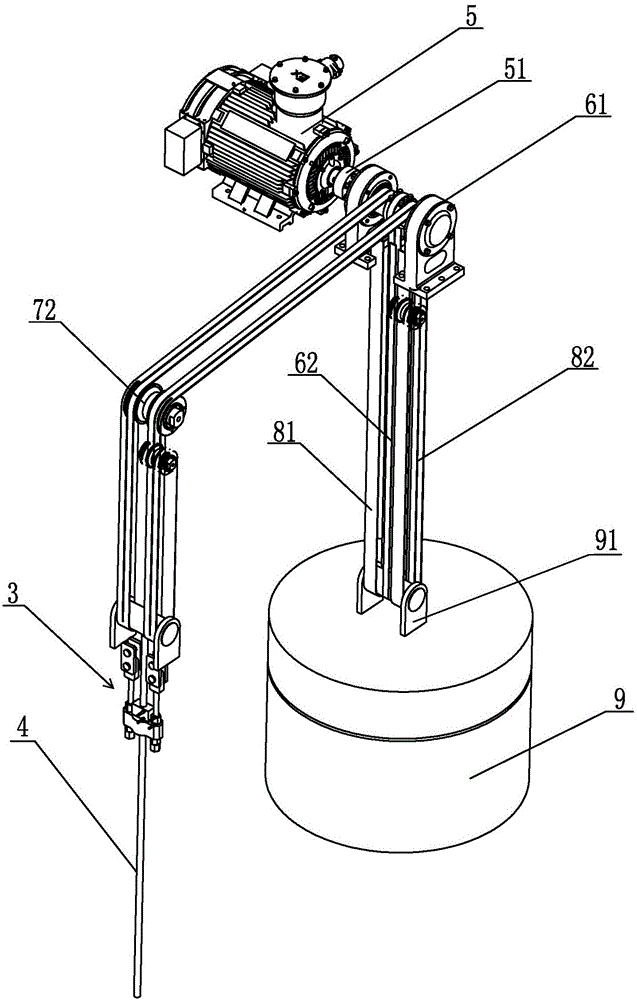

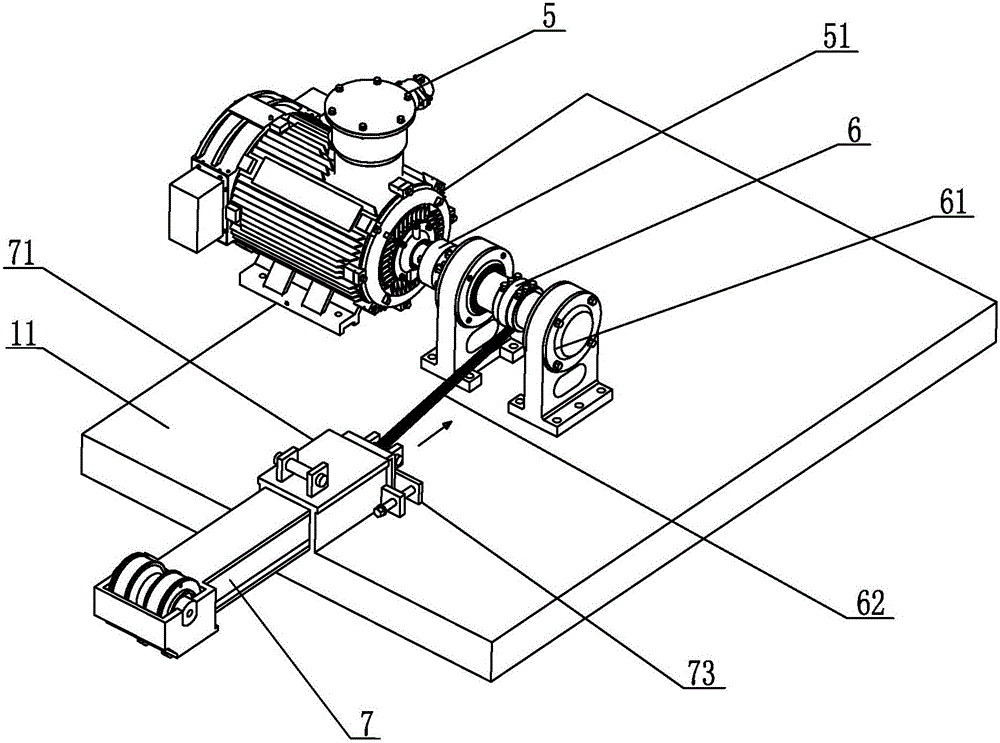

[0022] like Figure 1-Figure 9 The shown high-efficiency direct-drive pumping unit with single-acting pulley and single-fixed pulley includes a tower 2 fixed on a cement foundation 10, and a platform welding frame 1 is fixed on the top of the tower 2, and the platform is The upper platform 11 of the welding frame 1 is provided with a motor 5, a driving wheel 6, a guide seat 71 and a guide arm 7. The driving wheel 6 is fixed in the middle of the upper platform 11 through the driving wheel bracket 61, and the middle of the driving wheel 6 is rolled A first steel belt 62 is wound around, the motor 5 is fixed on one side of the driving wheel 6 and is connected with the driving wheel 6 through the coupling 51 , the guide seat 71 is fixed on one end of the upper platform 11 , and the guide seat 71 The upper end face of the guide arm 7 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com