Truck side guard rail mounting size measurement system and method based on machine vision technology

A technology of installation size and machine vision, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of affecting the measurement results, low measurement efficiency, environmental errors, etc., and achieve the effect of accurate detection data and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

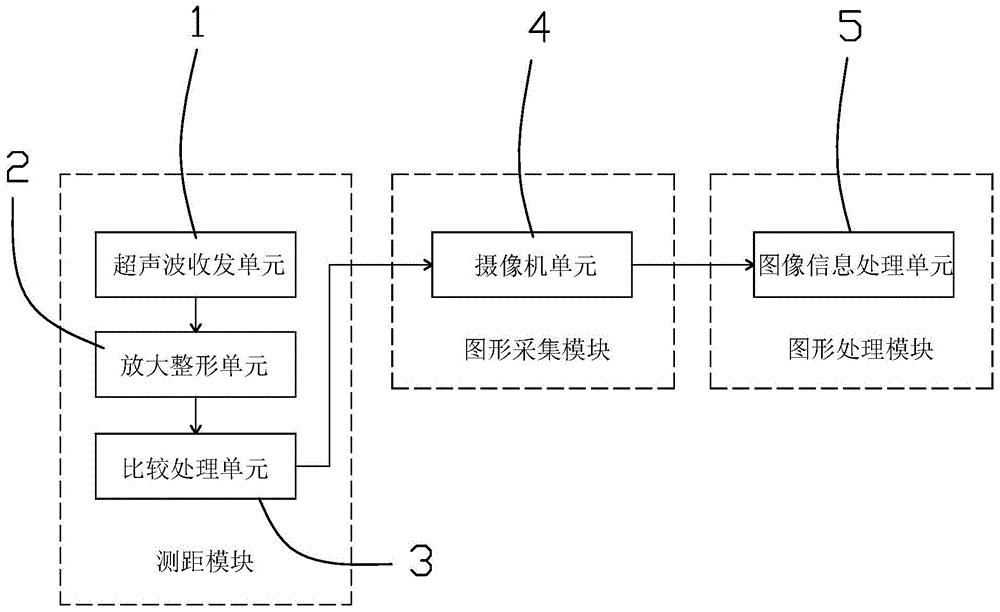

[0055] In this embodiment, a system for measuring the installation size of the truck side guardrail based on machine vision technology, such as figure 1 As shown, it includes a ranging module, a graphics acquisition module and a graphics processing module. The distance module includes an ultrasonic transceiver unit 1 , an amplification and shaping unit 2 and a comparison processing unit 3 connected in sequence. The graphic acquisition module includes a camera unit 4, the graphic processing module includes an image information processing unit 5, the comparison processing unit is connected to the camera unit, and the camera unit is connected to the image information processing unit.

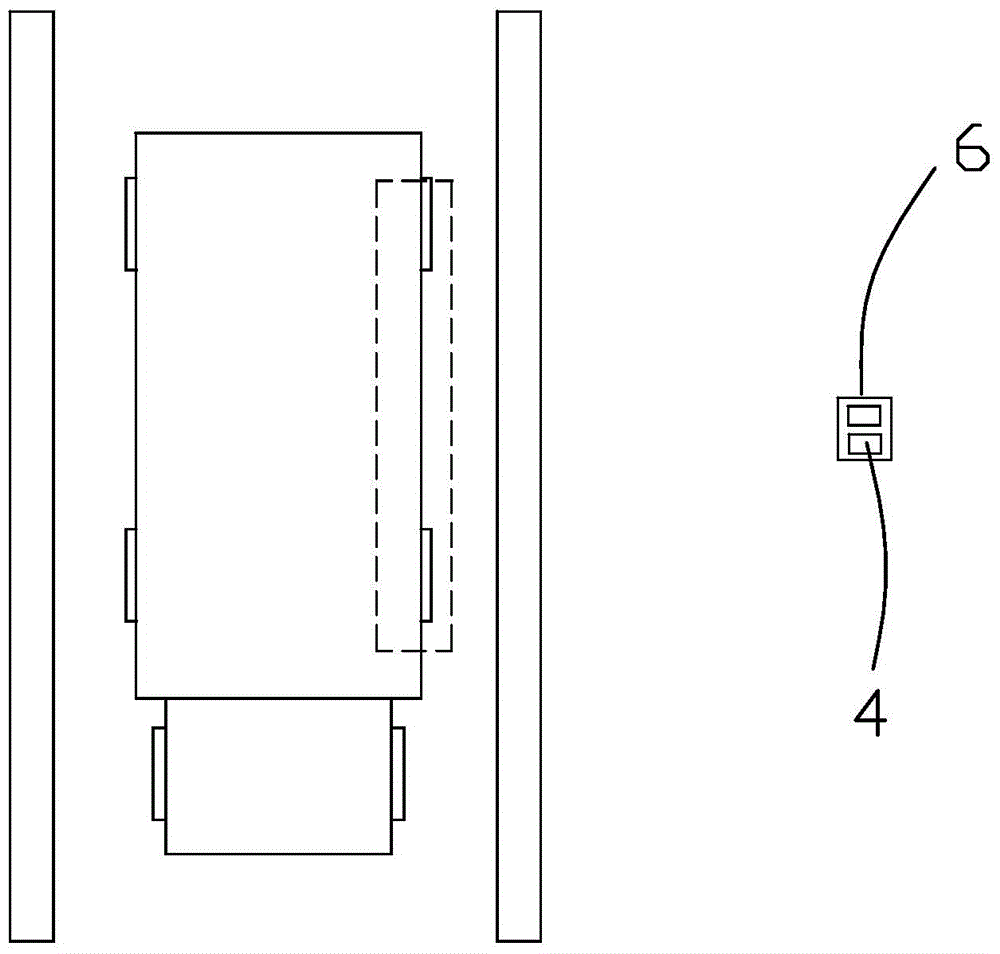

[0056] In this embodiment, the system is applied to various road toll stations. Its installation structure is as figure 2 As shown, the system is installed at the channel of the vehicle toll station, and the detection area is set in the channel of the vehicle, as shown in the dotted line in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com