A Beam Target for Ground Test of Ion Thruster

An ion thruster and ground test technology, which is applied in the testing of machines/structural components, instruments, engines, etc., can solve problems such as the influence of thruster working life, reduce temperature, reduce processing difficulty and test cost, and improve The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

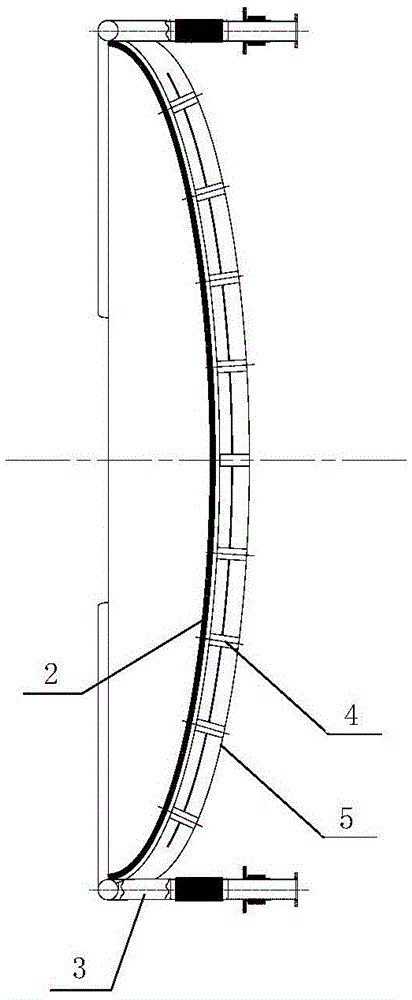

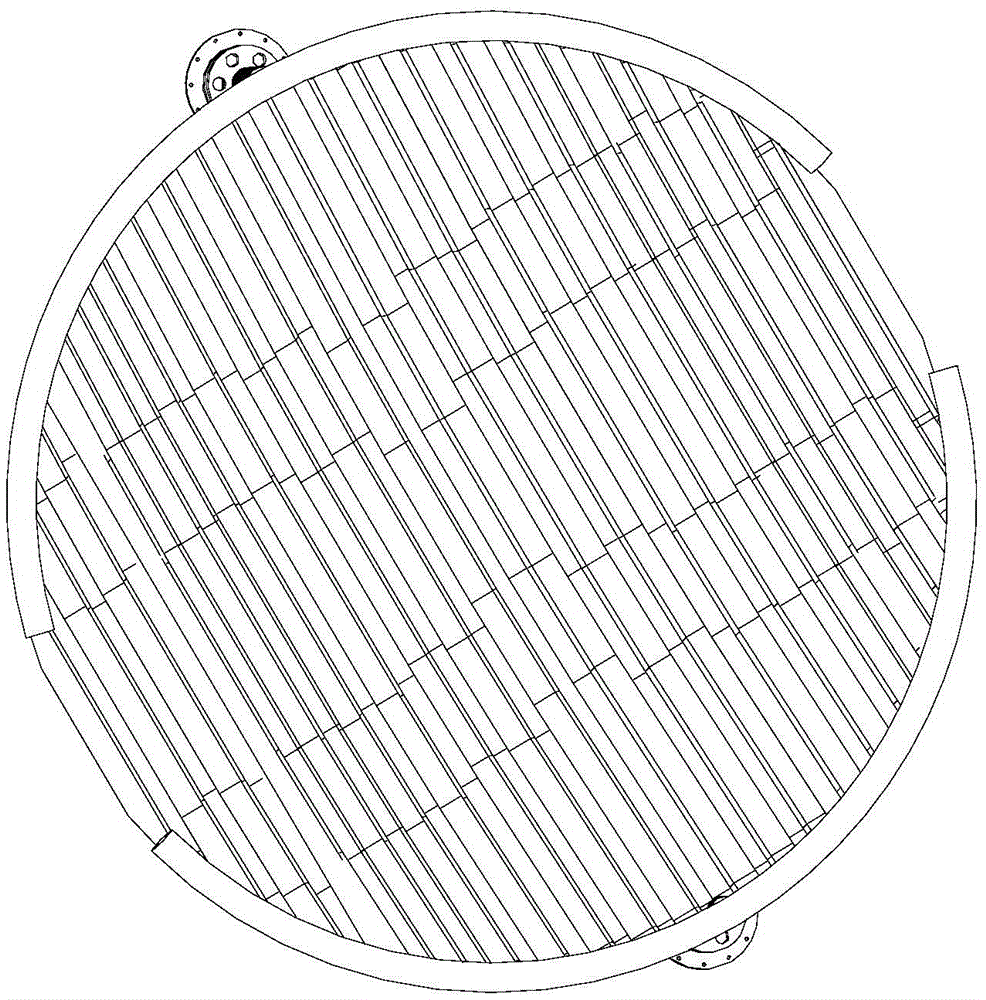

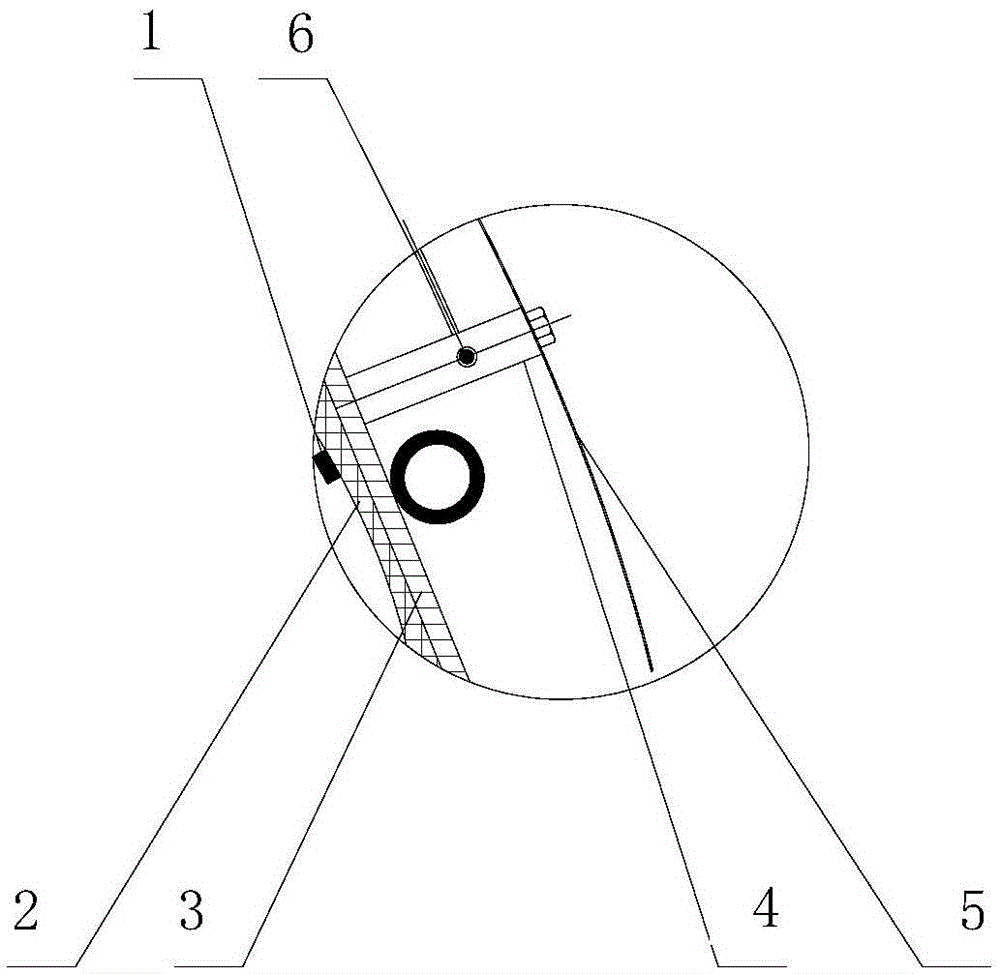

[0016] The invention provides a beam target for the ground test of an ion thruster, comprising a temperature measuring element 1, a high-purity graphite target surface 2, a heat-absorbing target body 3, an insulating support column 4, a reflective screen 5 and a heating body 6, wherein, The endothermic target body 3 is the main frame of the ion thruster ground test beam target, placed on the opposite end of the ion thruster in the ground test cabin; the inner surface of the endothermic target body 3 is an arc surface; high-purity graphite The target surface 2 is spliced by several rectangular high-purity graphite blocks. The thickness of the rectangular high-purity graphite block is 3-5mm, and the surrounding area of the rectangular high-purity graphite block is processed into a wedge shape, and the rectangular high-purity graphite block is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com