Flexible lamp strip and machining method thereof

A technology of flexible light strips and flexible materials, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of limiting the light-emitting angle and light-emitting uniformity of lamps, increasing the cost of gold wires, and complicated processes, so as to increase the bonding Strength and thermal conductivity, saving gold wire cost, uniform luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

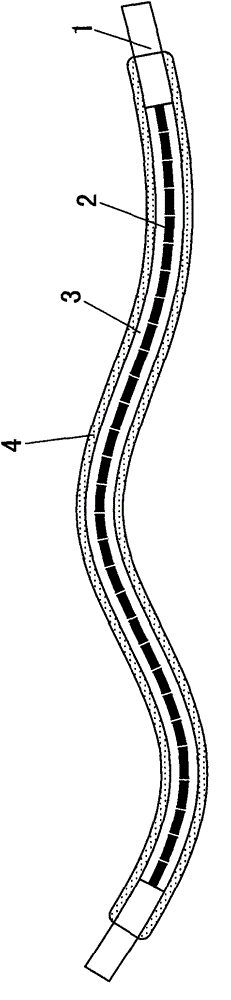

[0019] Such as figure 1 As shown, the flexible light bar of the present invention includes a strip bracket 1 made of flexible materials such as plastic or silicone and a plurality of inverted LED light-emitting chips 2, and the LED light-emitting chips 2 are blue light chips or red light chips or green light chips Or purple chip. The outer surface of the bracket 1 is electroplated or sintered with a metal layer 3 by means of electroplating or sintering. The support 1 is also provided with positive and negative electrode conductive connection points (not shown in the figure), and the positive and negative electrodes of a plurality of LED light-emitting chips 2 are bonded together with the positive and negative electrode conductive connection points through silver paste, and heated by high temperature. The silver paste is cured by baking. A series circuit of at least one LED light-emitting chip 2 or a parallel circuit of at least two LED light-emitting chips 2 or a series-para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com