Small constant-temperature air-cooling repetition-rate DPL (Diode Pump Laser) without TEC (ThermoElectric Cooler)

A pulsed laser, small technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of TEC temperature control failure, low heating efficiency, laser cavity deformation, etc., to achieve high driving stability, high electro-optical The effect of high efficiency and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

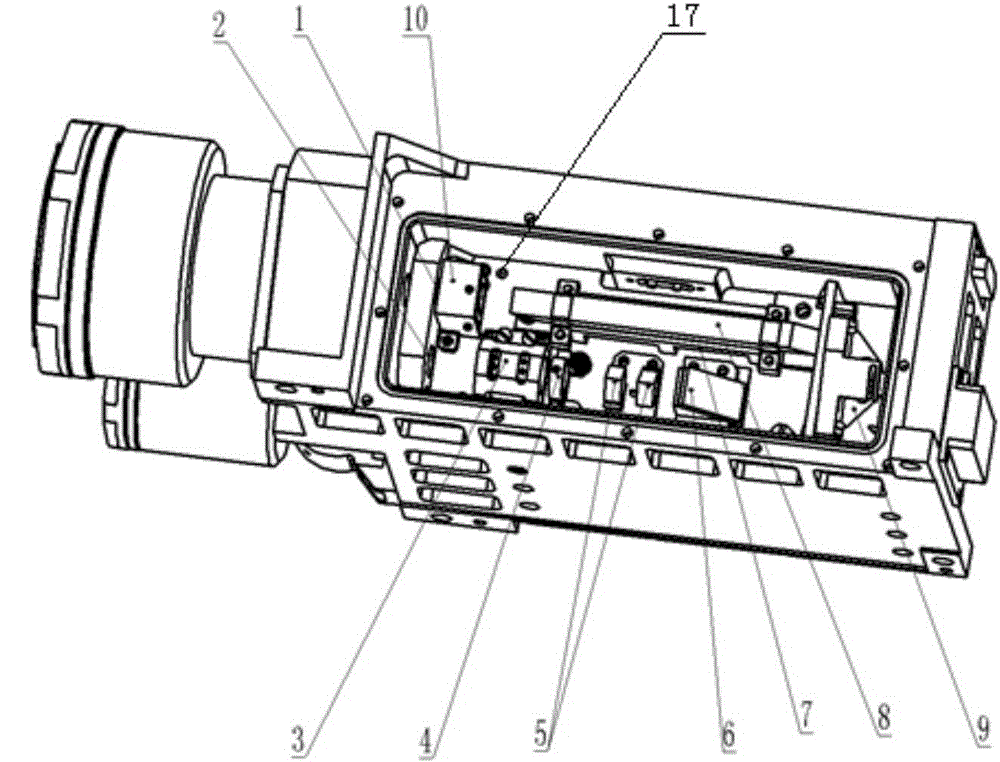

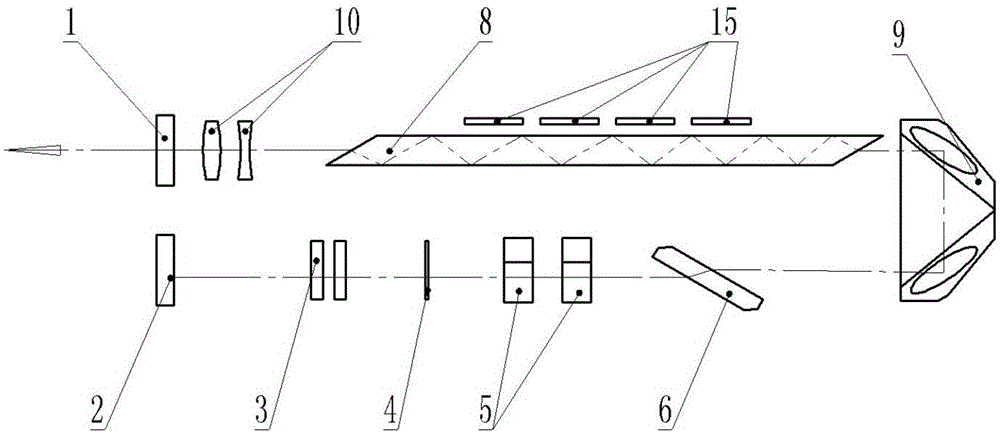

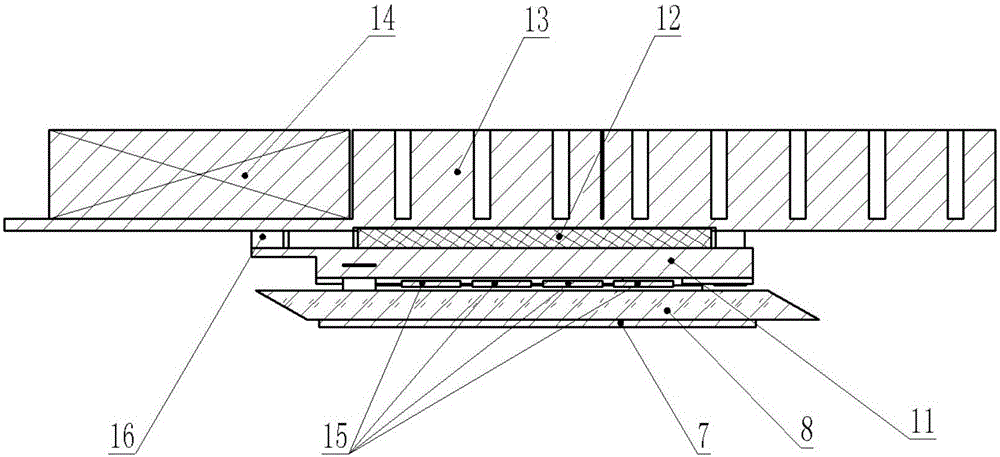

[0021] refer to figure 1 . In the embodiment described below, the non-TEC constant temperature small air-cooled repetitive frequency DPL laser uses a diode laser array pump source 15 with a wide temperature range of +40°C to +70°C installed on the cover plate of the box, and a heat sink 13 , High-efficiency ceramic heating plate 12, small high-speed cooling fan 14 and temperature sensor 16. Also include, the laser working medium 8 installed in the frame body 17 and its heat conduction and heat dissipation crystal seat 7, ceramic heating sheet 12, heat sink 13, high-speed cooling fan 14, laser resonant cavity and its optical elements, all optical elements are placed In a rectangular parallelepiped titanium alloy frame structure 17. The laser working medium 8 can be a strip-shaped medium or a cylindrical medium. The characteristic of its pump part is that the pump structural components composed of wide temperature range high-efficiency diode laser array pump source 15, cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com