Frequency-selective 355nm UV laser in a fiber end-pumped Brewster's angle cavity

A technology for ultraviolet lasers and fiber end faces, applied in lasers, laser components, phonon exciters, etc., can solve the problems of nonlinear crystal conversion efficiency easily affected by temperature changes, poor laser processing effect, and unstable laser power. , to achieve the effect of ensuring single-frequency laser output, improving electro-optic conversion efficiency, improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

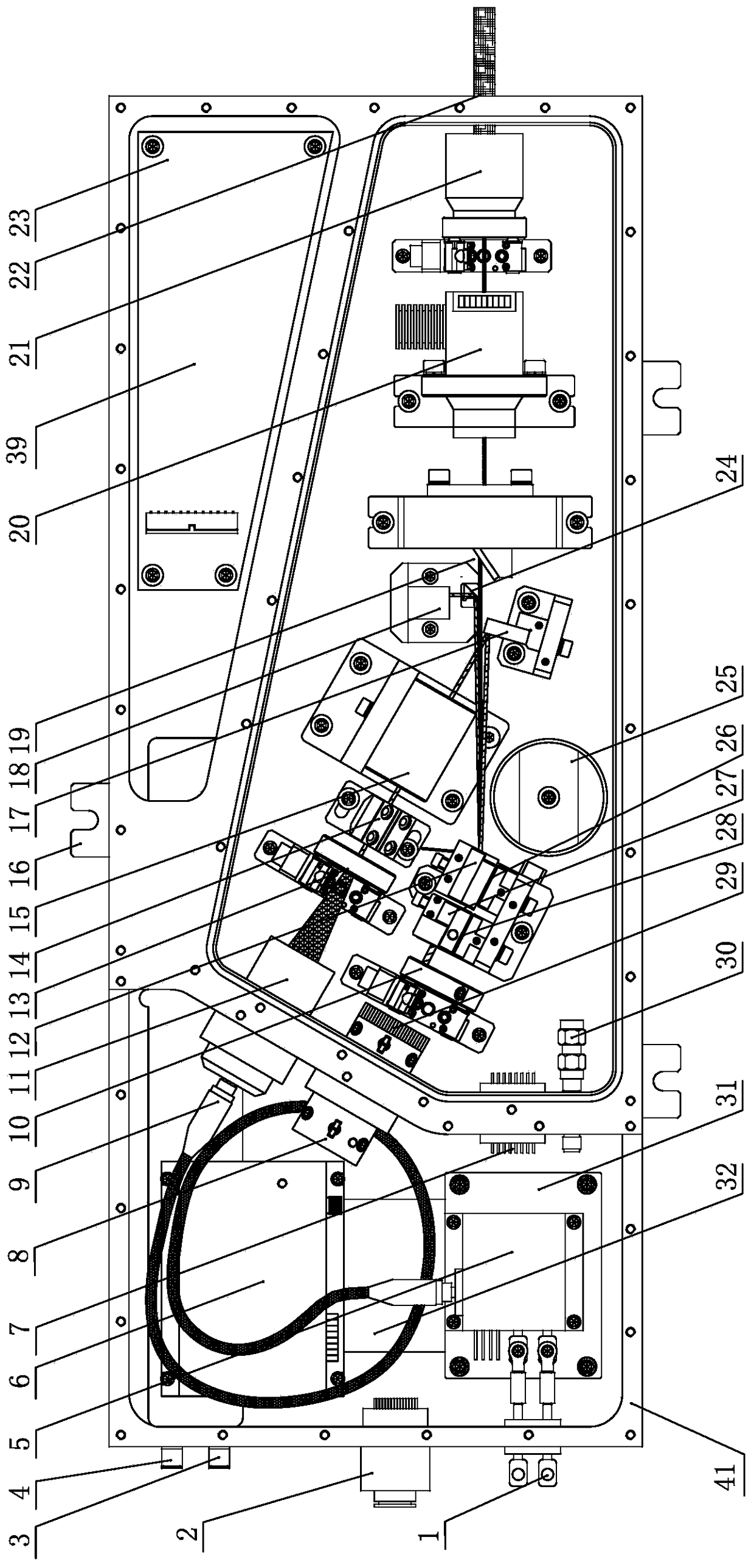

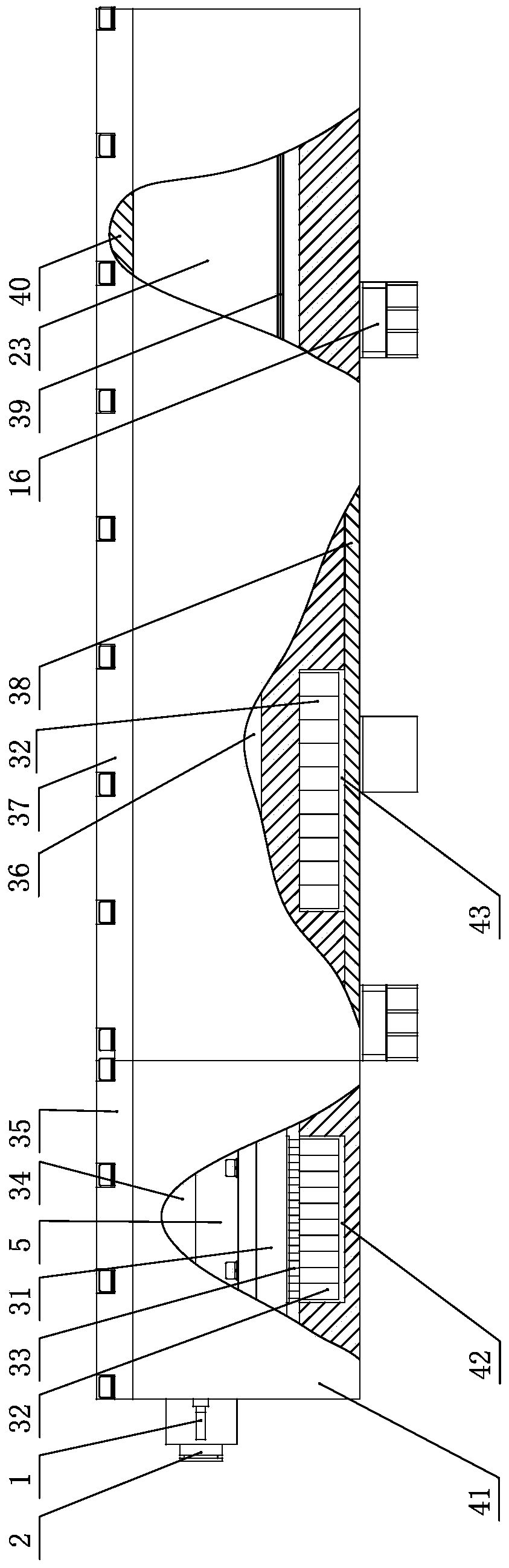

[0026] As shown in the figure: the frequency-selective 355nm ultraviolet laser in the fiber end-pumped Brewster angle cavity in the embodiment is mainly composed of the laser power interface (1) installed in the laser housing (41), the control signal aviation plug ( 2), water inlet (3), water outlet (4), 808nm semiconductor laser (5), Q switch driver (6), electrical transition terminal (7), laser indicator red light generator (8), 808nm output fiber ( 9), rear mirror (10), coupling head (11), triple frequency LBO crystal (12), plano-convex front mirror (13), YVO4 crystal (14), acousto-optic Q switch (15), anti-torque force Anchor (16), turning mirror (17), garbage light recycling station (18), substrate (19), power attenuator (20), beam expander (21), output window mirror (22), turning prism ( 24), desiccant isolation plate (25), triple frequency LBO crystal T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com