A high power polarized laser device

A laser device and high-power technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of inability to achieve high-power polarized laser output, serious thermal effects, and difficulty in specific wavelength output, and achieve high-power Polarized laser output, excellent thermodynamic and mechanical properties, improved electro-optical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

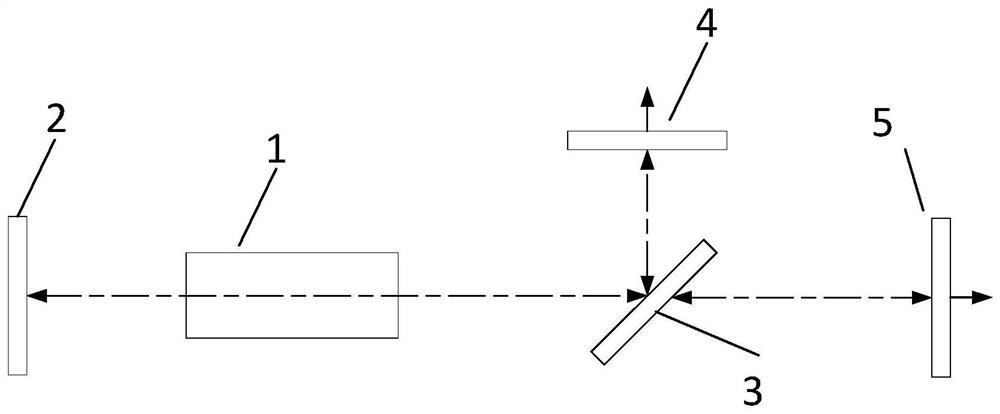

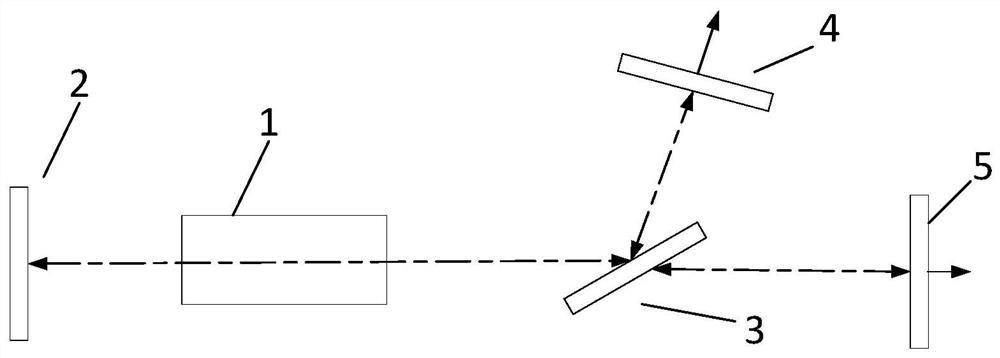

[0028] Based on the above findings, the present invention provides a high-power polarized laser device, including a high-reflection mirror 2, a laser gain module 1, a polarizer 3, an s-light output mirror 4 and a p-light output mirror 5, wherein the high-reflection mirror 2, the laser gain The module 1 and the polarizer 3 are placed on the same optical axis in sequence, the s light output mirror 4 is located on the reflected light path of the polarizer 3 and is perpendicular to the transmission direction of the reflected light, and the p light output mirror 5 is located on the polarizer 3 to transmit. The light path is perpendicular to the transmission direction of the transmitted light. The s-light output mirror 4 reflects part of the s-polarized laser on the reflected light path of the polarizer 3 back to the original path, forms a resonant cavity with the high-reflecting mirror 2, and partially emits to form a polarized laser, and the p-light output mirror 5 will Part of th...

no. 2 example

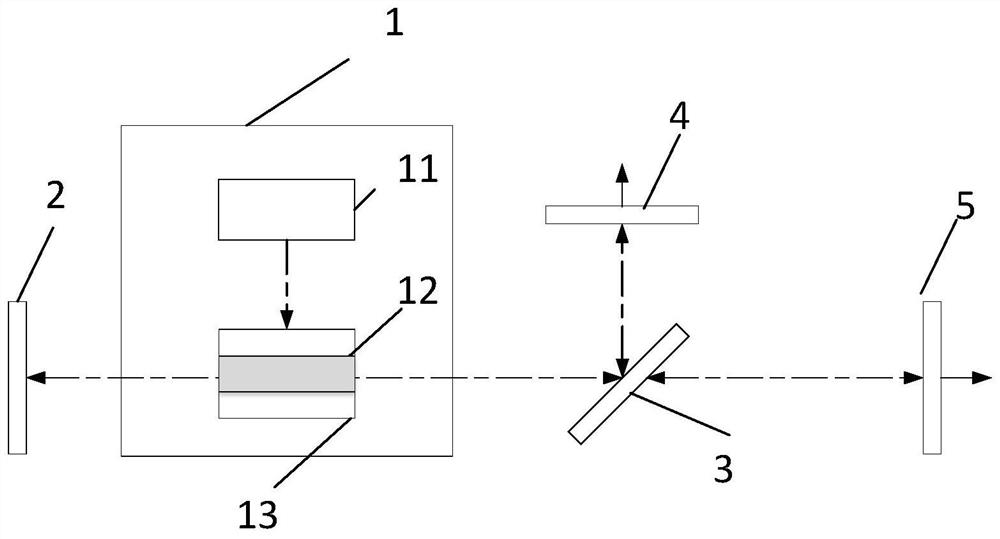

[0034] Another embodiment of the high-power polarized laser device of the present invention is as follows: image 3 As shown, it includes a high-reflection mirror 2, a laser gain module 1, a polarizer 3, an s-light output mirror 4 and a p-light output mirror 5, wherein the high-reflection mirror 2, the polarizer 3, the s-light output mirror 4 and the p-light output mirror The structure of the light output mirror 5 is the same as that of the previous embodiment, and will not be repeated here. The laser gain module 1 further includes a pump source 11 , a laser gain medium 12 and a heat sink 13 , wherein the pump source 11 is a side pump. The side pump source is a laser diode (Laser Diode), which is located on the side of the laser gain medium 12 and is used to pump the laser gain medium 12. In this embodiment, the wavelength of the side pump source is 780 nm. Wavelength, the 780nm waveband refers to the waveband of 780nm to 790nm. Preferably, a laser diode with a wavelength of 7...

no. 3 example

[0038] In order to increase the power of the polarized laser device and reduce the thermal effect, the high-power polarized laser device of the present invention can also be as follows: Figure 5 As shown, the difference from the previous embodiment is that the high-power polarized laser device includes at least two laser gain modules 1, and the laser gain modules 1 are connected in series. For the convenience of description, the embodiment of the present invention uses two laser gain modules. Module 1 is taken as an example for description. The structure of the laser gain module 1 is the same as that of the laser gain module using the side-pump pump source in the previous embodiment. In this implementation, the laser gain module pumps a Tm:YAG crystal through a 785nm pump source, and achieves a mid-range 2μm band. Laser output at a specific wavelength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com