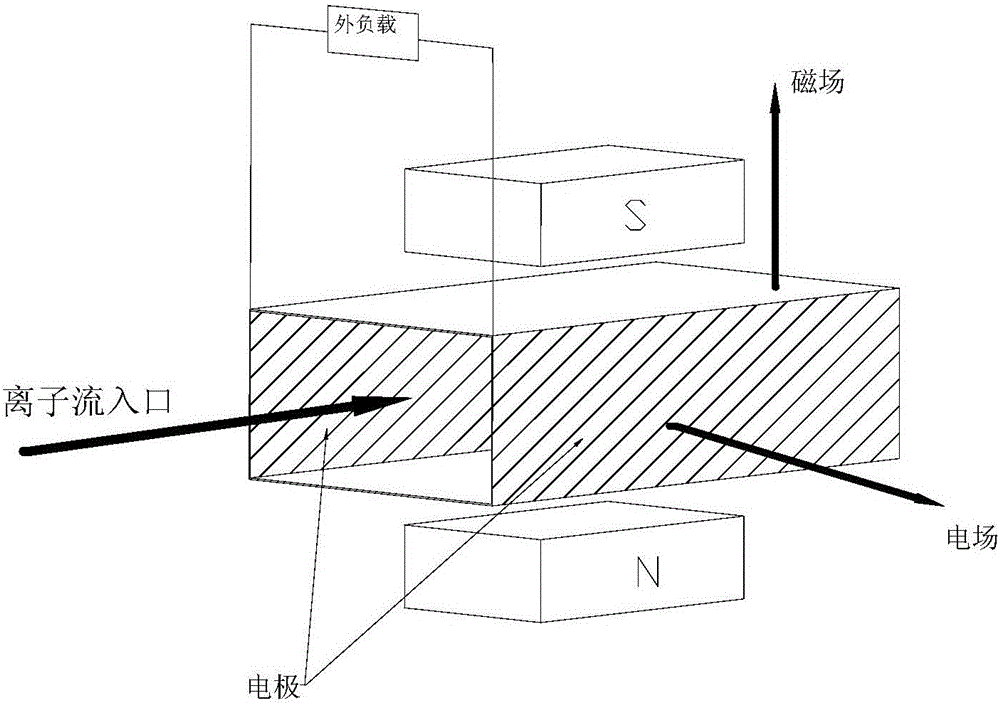

Magnetohydrodynamic power generation system capable of directly converting heat energy into electric energy

A magnetic fluid power generation and thermal energy conversion technology, which is applied in the direction of electrical components, electromechanical devices, and joint combustion mitigation, can solve the problems of inability to achieve pollution-free power generation, increase system manufacturing costs, and inconsistent development goals, and achieve material and safety performance The effect of low requirements, no need for preparation work, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

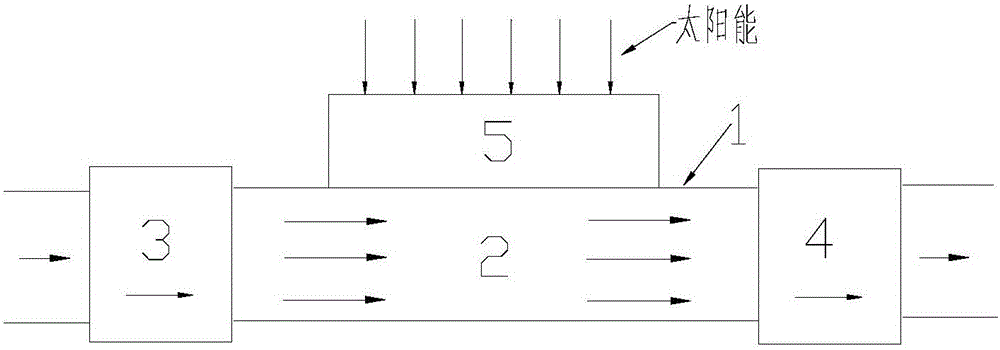

[0025] see figure 2 and Figure 4 , the present invention is a magnetic fluid power generation system that directly converts thermal energy into electrical energy, including an annular closed channel 1, and the channel 1 is provided with a first one-way valve 3 and a second one-way valve 4 arranged in the same direction, the channel 1 is filled with magnetic fluid 2, the one-way valve is used to control the flow direction of the magnetic fluid 2, and a solar panel 5 for heating the magnetic fluid 2 by means of solar energy is arranged between the two one-way valves;

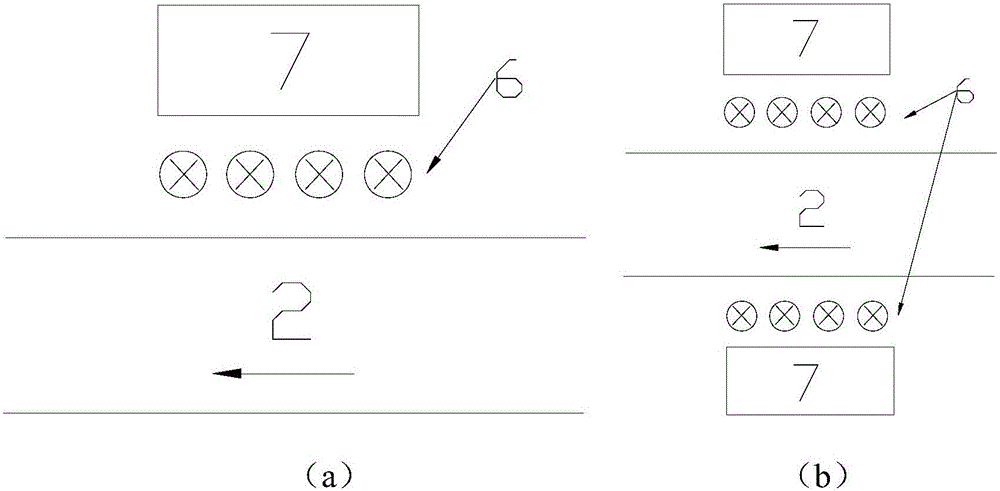

[0026] It also includes a magnet 7 arranged parallel to the channel 1. A group of wires 6 perpendicular to the magnetic field are arranged in the gap between the magnet 7 and the channel 1. Both ends of the wire 6 are connected to a power storage device or connected to a power grid. When work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com