Die and method for manufacturing inner and outer pipe workpiece with separation ribs in middle through extrusion method

An extrusion method and intermediate belt technology, applied in the direction of metal extrusion dies, etc., can solve the problems of high working stress, unchangeable, complex die processing, etc., and achieve the effect of high strength and easy demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

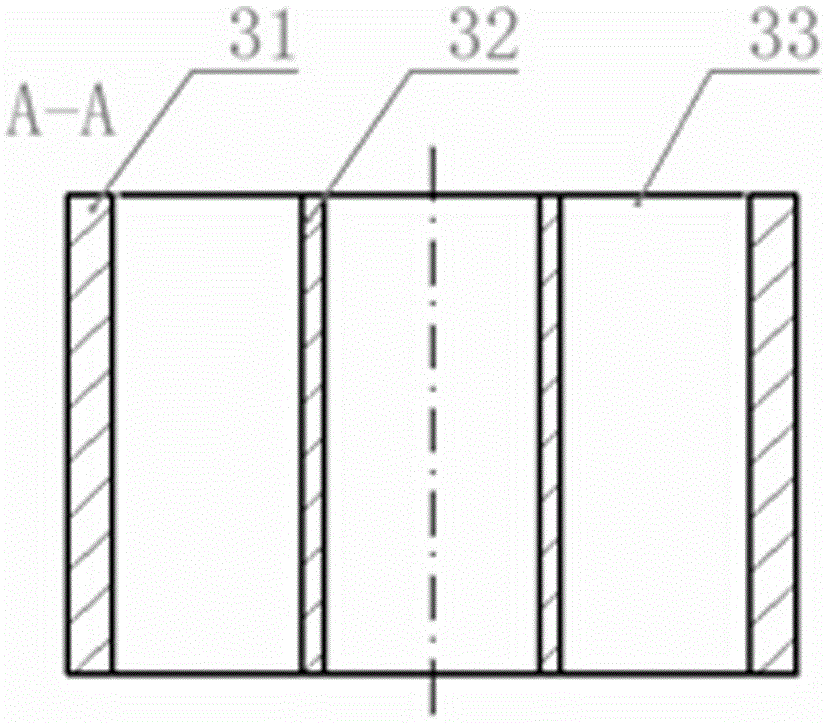

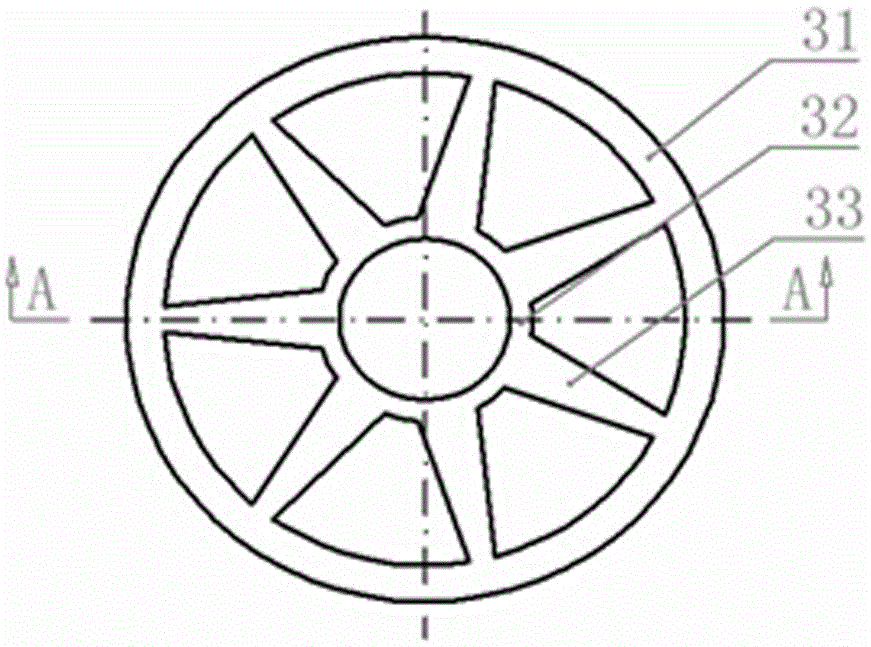

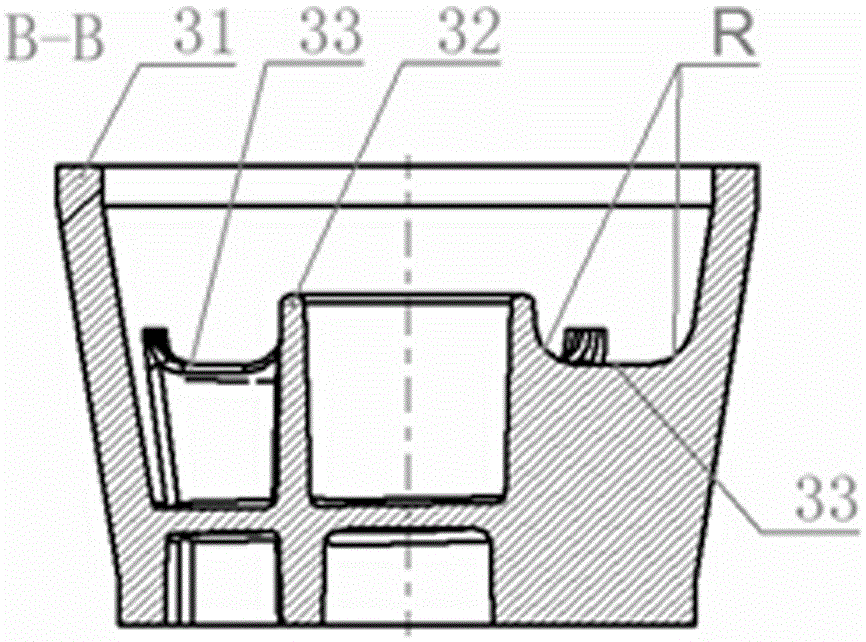

[0055] see Figure 1 to Figure 16 , a kind of die of the present invention adopts extrusion method to manufacture inner and outer double-pipe middle belt partition bar workpiece, it is characterized in that, comprises punch 2 and die 7 that coaxially arrange up and down, the top of punch 2 is fixed on the top of upper template 1 Below, the die 7 is fixed on the top of the lower formwork 11, and the push rod 12 is slidably installed in the through hole in the middle part of the lower formwork 11.

[0056] An inner tube forming groove 23 is provided at the middle of the bottom end of the punch, and several radial rib forming grooves 24 are arranged on the outer periphery of the inner tube forming groove 23. Die head 21, in this inner pipe forming groove 23 is the central punch head 22 corresponding to the bottom of the inner pipe.

[0057] The bottom of described die 7 is provided with die base plate 9, is provided with the concavo-convex structure corresponding with described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com