3D printing achieving method, printing system and jet flow control method under microgravity environment

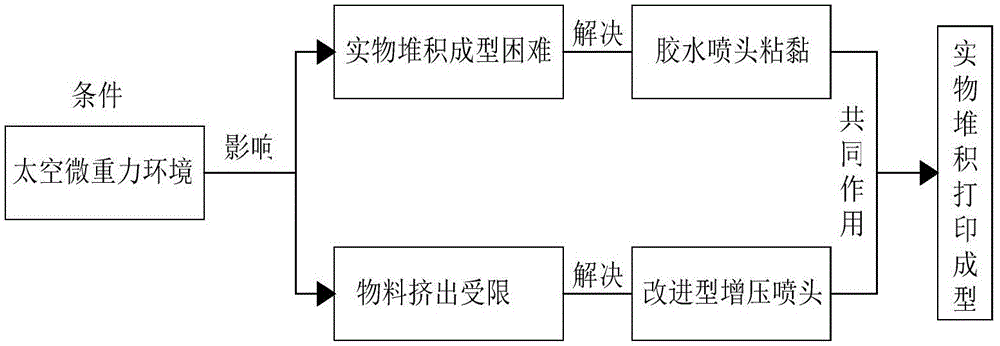

A printing system and 3D printing technology, applied in the printing system, spinneret flow control, and 3D printing implementation to reduce budget, enhance reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

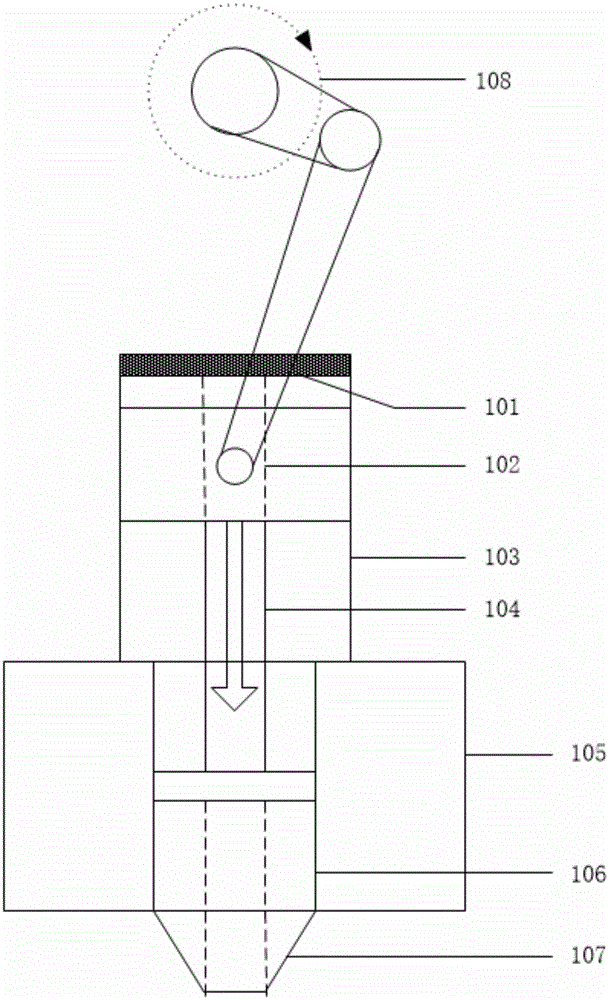

[0031] Such as figure 1 As shown, it is the front view of the 3D printing piston pressurized nozzle of the present invention; it includes a delivery pipeline shrinkage 101, a delivery pipeline inner channel 102, a delivery pipeline 103, a piston 104, a heating mechanism 105, and a delivery tube Road 106, extrusion outlet 107, mechanical drive 108. Among them, the working principle of the piston booster pump is similar to that of a pressure booster, which applies a very low pressure to the large-diameter driving piston 104 , and generates a high pressure when the pressure acts on a small-area passive piston 104 . The material enters through the passage 102 in the feeding pipeline, as shown by the dotted line in the figure; the connecting rod of the piston 104 is hollow, and runs through the passage 102 in the feeding pipeline in the middle (that is, the passage in the feeding pipeline runs through the hollow connecting rod Inside), the filamentous material is driven by an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com