Thin film flocked-type high-elastic flame-retarding warm-keeping sheet material and preparation method thereof

A flake material, flocking technology, applied in the textile field, to achieve the effect of reducing the amount of use, smoothing the surface and improving warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] (3) Preparation of mixed powder: uniformly mix hot melt powder and flame retardant powder to prepare hot melt powder and flame retardant powder mixed powder 6, 6 , ;

[0039] (4) Sprinkle powder: Sprinkle the mixed powder 6 of hot-melt powder and flame-retardant powder in the upper fiber net 1, and the lower fiber net 1 , Sprinkle the mixed powder of hot melt powder and flame retardant powder inside 6 , ;

[0040] (5) Drying: Mix powders 6 and 6 sprinkled with hot-melt powder and flame-retardant powder respectively. , The upper fiber web 1, the lower fiber web 1 , to dry;

[0041] (6) Hot-press lamination: coat the upper flocking film substrate 3 and the upper hot-melt film 2 on the upper fiber web 1, and make the upper hot-melt film 2 on the upper flocking film substrate 3 and the upper fiber web. Between the nets 1, the upper hot-melt film 2 is melted by hot pressing, and the upper flocking film substrate 3 is consolidated on the upper fiber web 1; the lower floc...

Embodiment 1

[0050] Strip-shaped film flocking type mechanically-laid high-elastic flame-retardant and warm-keeping sheet material and its preparation method:

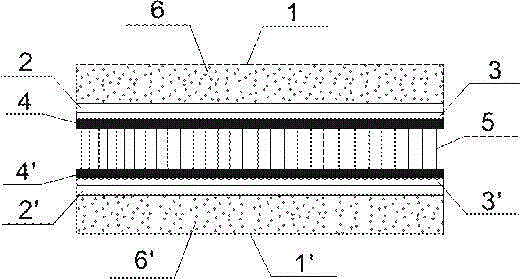

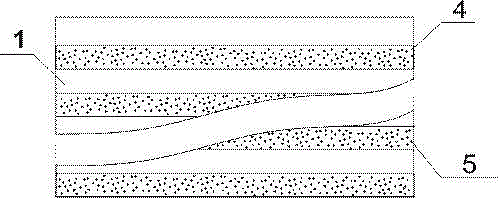

[0051] see figure 1 , figure 2 , film-flocked high-elastic flame-retardant thermal sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, fluff 5, lower adhesive film 4 ', the lower flocking film substrate 3', the lower hot-melt film 2', the lower fiber web 1 , , Mixed powder of hot melt powder and flame retardant powder 6, 6 , . The upper fiber web 1 and the lower fiber web 1' are three-dimensional crimped hollow polyester fibers with a fineness of 3D and a length of 51mm and low-melting fibers with a fineness of 3D and a length of 51mm and a melting point of 110°C. %: 20% is opened and mixed, and the fiber web prepared by mechanical carding of short fibers. A mixed powder 6 of hot-melt powder and flame-retardant powder is sprinkled inside the upper fiber w...

Embodiment 2

[0067] Lattice-shaped film flocking type mechanically-laid high-elastic flame-retardant and warm-keeping sheet material and its preparation method:

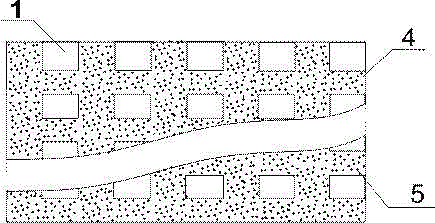

[0068] see figure 1 , image 3 , film-flocked high-elastic flame-retardant thermal sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, fluff 5, lower adhesive film 4 ', the lower flocking film substrate 3', the lower hot-melt film 2', the lower fiber web 1 , , Mixed powder of hot melt powder and flame retardant powder 6, 6 , . The upper fiber web 1 and the lower fiber web 1' are three-dimensional crimped hollow polyester fibers with a fineness of 3D and a length of 51mm and low-melting fibers with a fineness of 3D and a length of 51mm and a melting point of 110°C. %: 20% is opened and mixed, and the fiber web prepared by mechanical carding of short fibers. A mixed powder 6 of hot-melt powder and flame-retardant powder is sprinkled inside the upper fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com