A tilting quadrotor aircraft

A technology for tilting quadrotors and aircrafts, which is applied to aircrafts, rotorcraft, and aircraft parts, etc. It can solve the problems of quadrotors’ performance changes and increased resistance, and achieve the effects of simple structure, reduced resistance, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

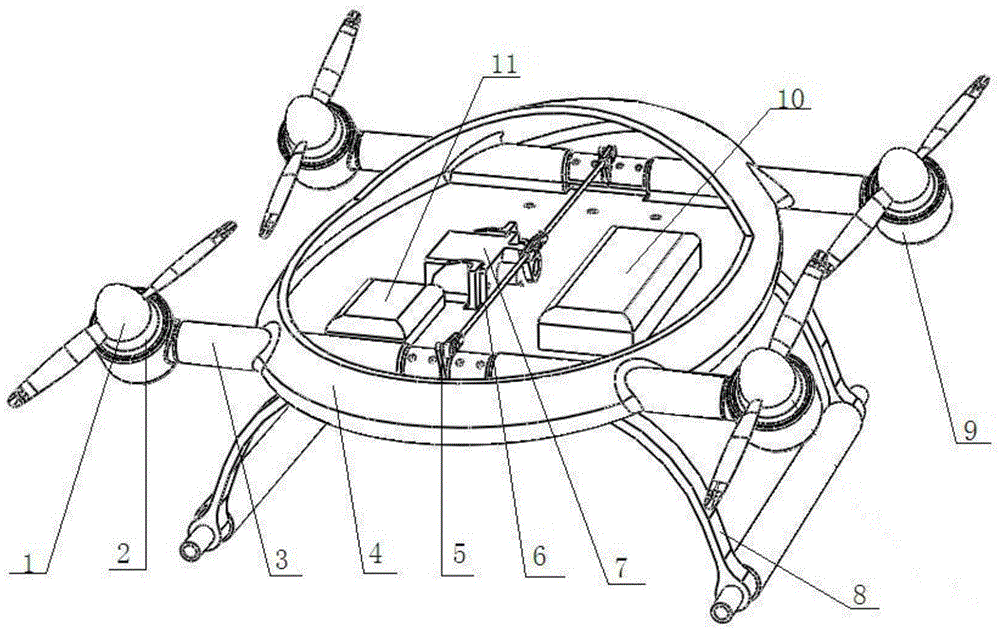

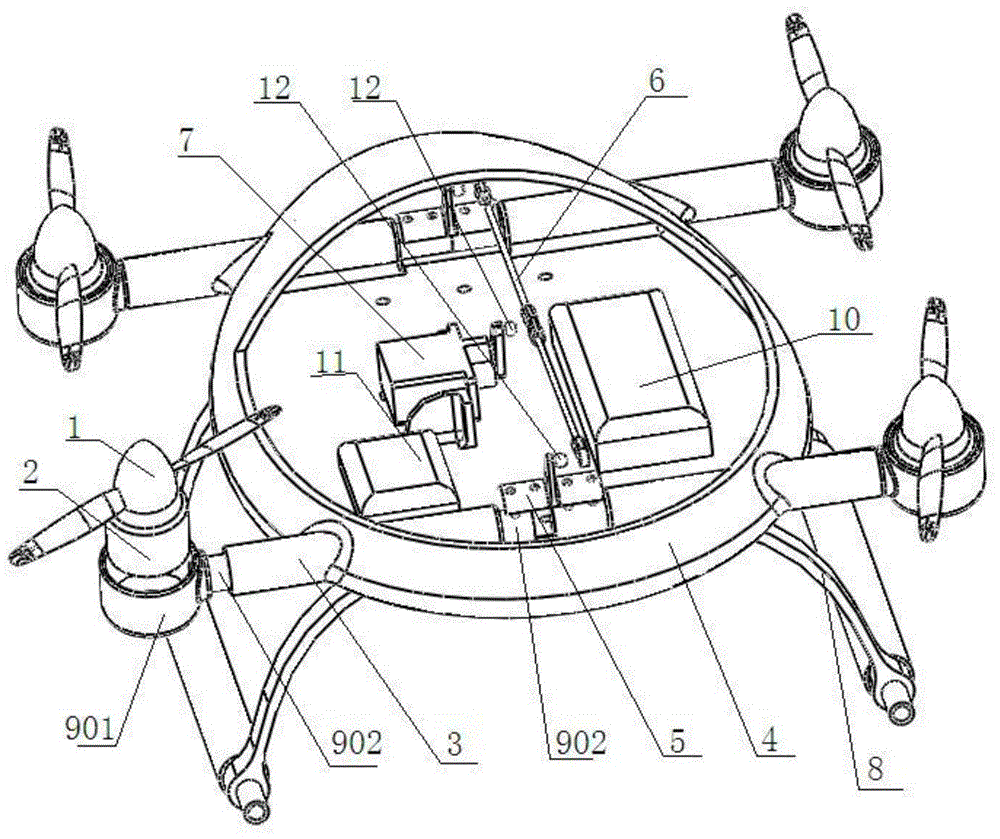

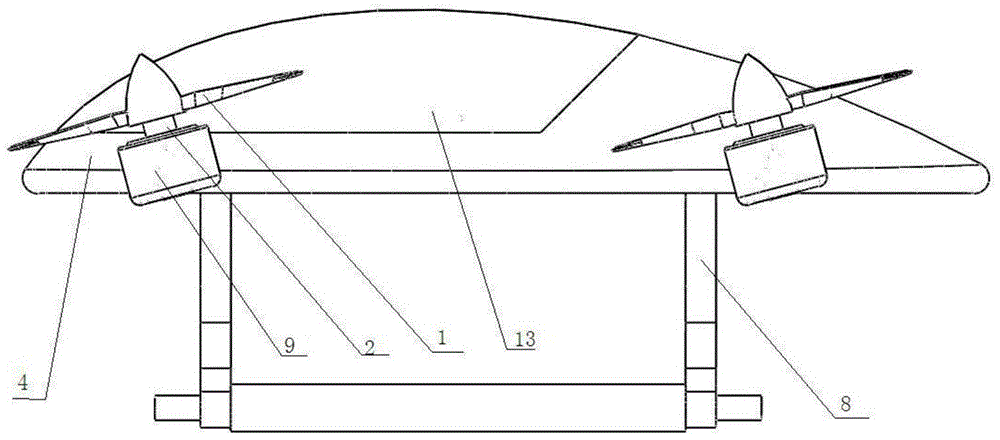

[0029] The invention provides a tilting quadrotor aircraft, such as Figure 1 ~ Figure 3 As shown, it includes a flying rotor 1, a brushless DC motor 2, a fixed pipe 3, a fuselage 4, a tilting rocker arm 5, a connecting rod 6, a tilting servo 7, a landing gear 8, a rotor arm 9, a power supply unit 10, Flight control system 11, ball head 12, cockpit cover 13. The tilting rocker arm 5, connecting rod 6, and tilting steering gear 7 form a tilting servo unit, and the flight rotor 1 and brushless DC motor 2 form a power unit.

[0030] The fuselage 4, landing gear 8, and rotor arm 9 are all made of carbon fiber materials, and the fuselage 4 left front, right front, right rear, and left rear positions are provided with fixed pipes 3 for installing and fixing the rotor arm 9; The tubes 3 are bonded on the fuselage 4, the two fixed tubes 3 at the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com