Integrated two-stage reverse osmosis device

A reverse osmosis device, an integrated technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of impractical implementation, difficulty in balancing flow and pressure, and increased investment costs, etc. problem, to achieve the effect of improved reliability, high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

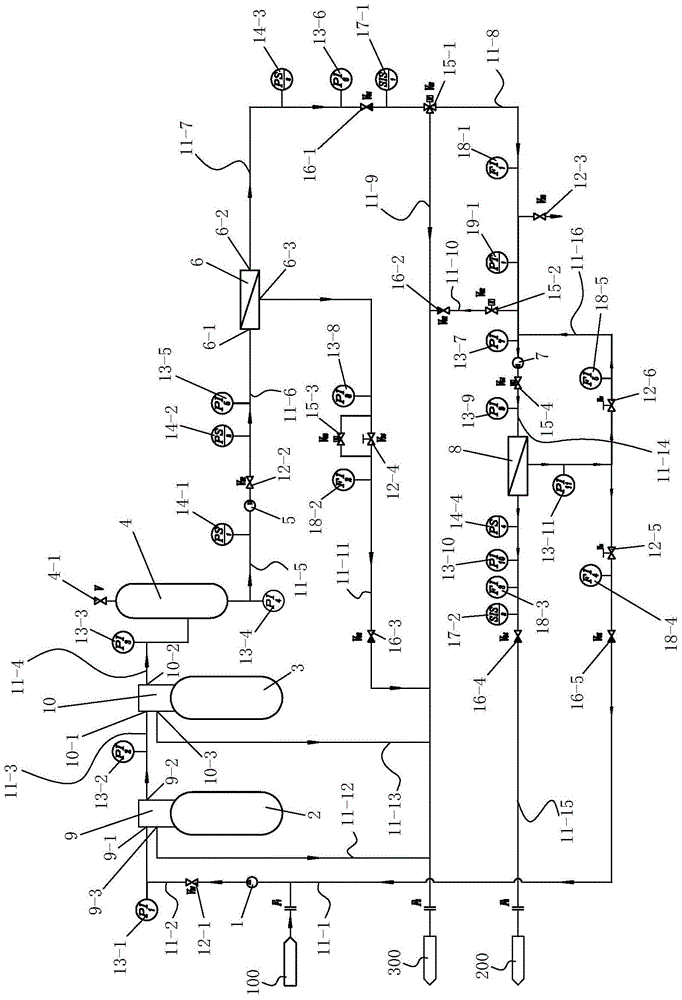

[0038] See figure 1 , the integrated two-stage reverse osmosis device of the present invention includes a first booster pump 1, a multimedia filter 2, an activated carbon filter 3, a security filter 4, a first high-pressure pump 5, a first reverse osmosis membrane stack 6, a first Two high-pressure pumps 7 , a second reverse osmosis membrane stack 8 , a first multi-way valve 9 and a second multi-way valve 10 .

[0039] The water inlet of the first booster pump 1 communicates with the raw water inlet 100 through the first pipeline 11-1. The first multi-way valve 9 is arranged on the multimedia filter 2 . The water outlet of the first booster pump 1 communicates with the first interface 9-1 of the first multi-way valve 9 through the second pipeline 11-2. The second pipeline 11-2 is provided with a first manual valve 12-1 and a first pressure gauge 13-1 in sequence. The second port 9-2 of the first multi-way valve 9 communicates with the first port 10-1 of the second multi-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com