Continuous loose fiber dyeing device

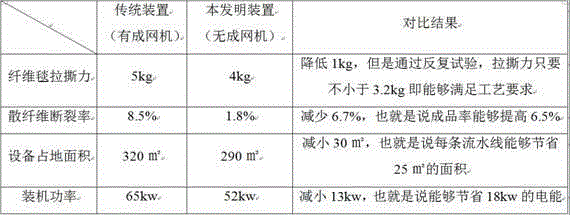

A dyeing device and loose fiber technology, which is applied in spray/jet textile material treatment, textile material carrier treatment, etc., can solve the problems of complex assembly line equipment, large footprint, and large power consumption, so as to improve spinnability and occupy a large area. Effect of reduced land area and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below by means of the accompanying drawings and examples.

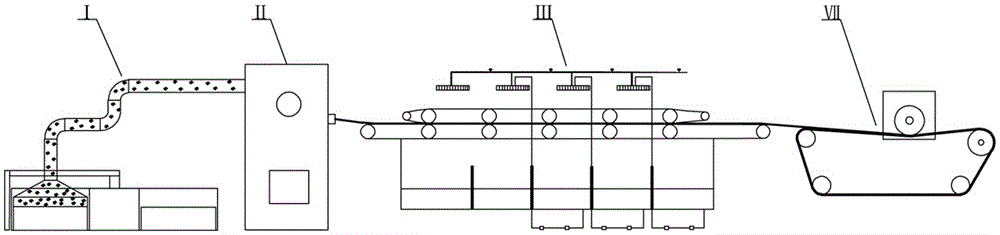

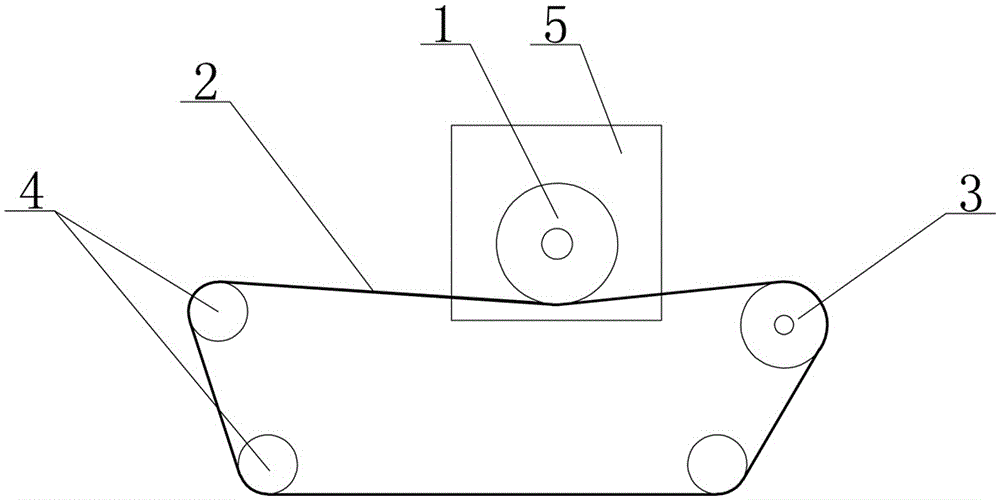

[0015] Such as figure 1 Shown: a continuous bulk fiber dyeing device, which is composed of a cotton catching machine I, a cotton box II, a padding dyeing machine III and a lapping machine VII arranged in sequence.

[0016] Below is the technological process of continuous bulk fiber dyeing device of the present invention processing loose fiber:

[0017] (1) Cotton picking: Grab the loose fibers from piles of loose fibers through the cotton picking machine I, and feed the fluffy loose fibers into the cotton box II.

[0018] (2) Blanket formation: The fluffy loose fibers are pressed into blanket-like loose fibers through the cotton box II, and the blanket-formed loose fibers are transported to the padding dyeing machine III.

[0019] (3) Pad dyeing: through the pad dyeing machine III, the horizontal guide belt is clamped and conveyed, and squeezed and sprayed alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com