A bridge expansion joint structure

A technology for expansion joints and bridges, used in bridges, bridge parts, bridge construction, etc., can solve problems such as dislocation or limitation of deformation and displacement of expansion joints, damage of expansion joints, and health effects of expansion joints, achieving convenient, fast, and good construction. Strength, the effect of avoiding the phenomenon of bridge jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

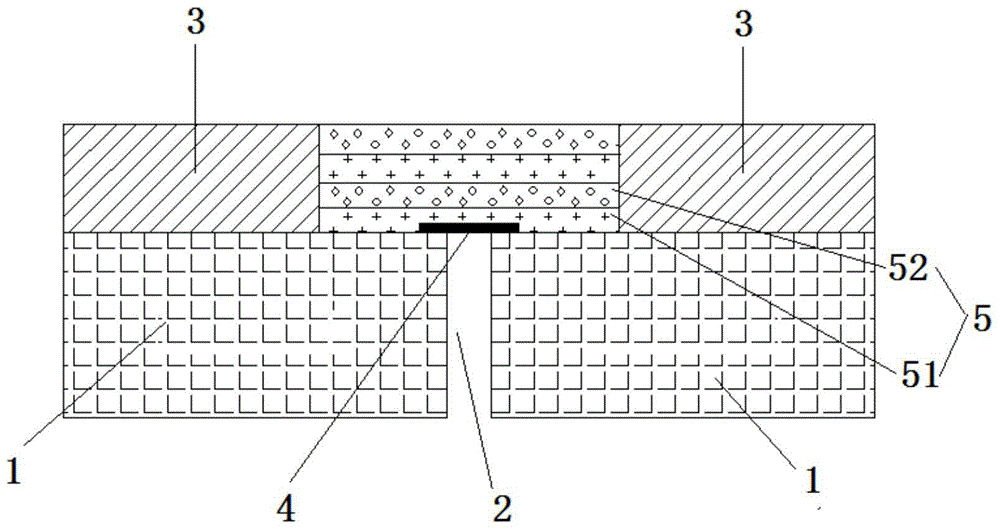

[0039] Referring to the accompanying drawings, a bridge expansion joint structure includes an expansion joint 2 and a sealing structure arranged on the expansion joint, the gap between two adjacent beam plates 1 forms the expansion joint 2, and each beam A bridge deck pavement 3 is laid on the slabs 1, and the bridge deck pavement 3 is shorter than the beam slab 1 to leave an installation gap,

[0040] The sealing structure includes a seam-spanning plate 4 and a sealing layer 5;

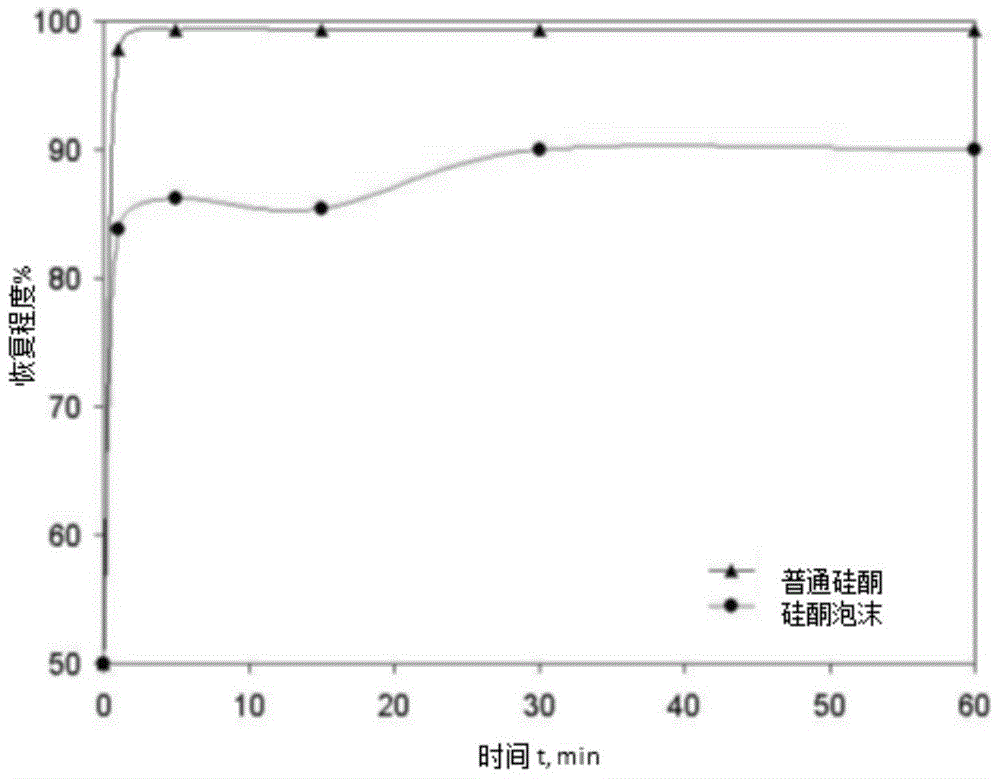

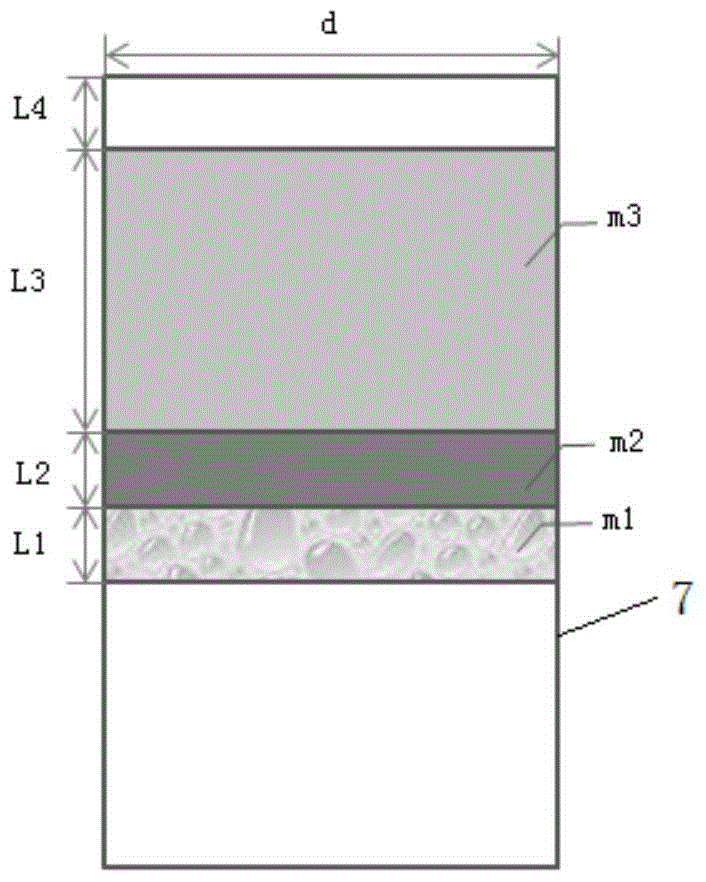

[0041] The seam-span board 4 is laid on the expansion joint 2 and completely covers the expansion joint 2; the adjacent girder slabs 1 and the deck pavement layers 3 respectively laid are enclosed on the seam-span board 4 A sealing groove is formed, and the sealing groove is alternately filled with the sealant layer 51 formed by the silicone foam sealant and the graded crushed stone layer 52, and the sealant layer 51 is close to the cross-span The board 4, the upper surface of the sealing layer 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com