Automatic panel trimming and plastering machine for full concrete faced rockfill dam concrete panel construction line

A face rockfill dam and face plate technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of construction period, quality, safety, slow sliding form shifting speed, and many safety hazards, etc., and achieve the improvement of rockfill dam face Concrete construction progress, reduction of construction safety accidents, and reduction of construction safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing:

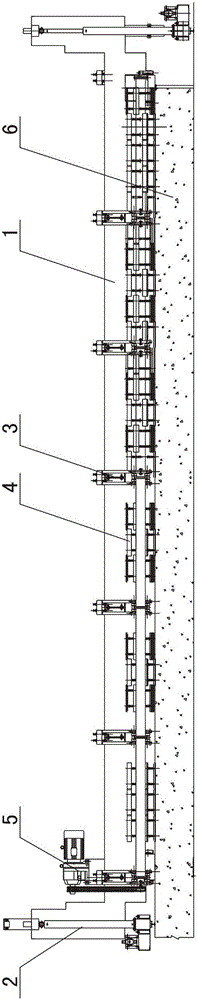

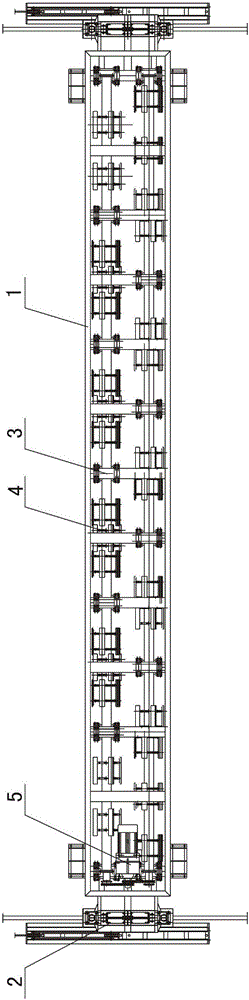

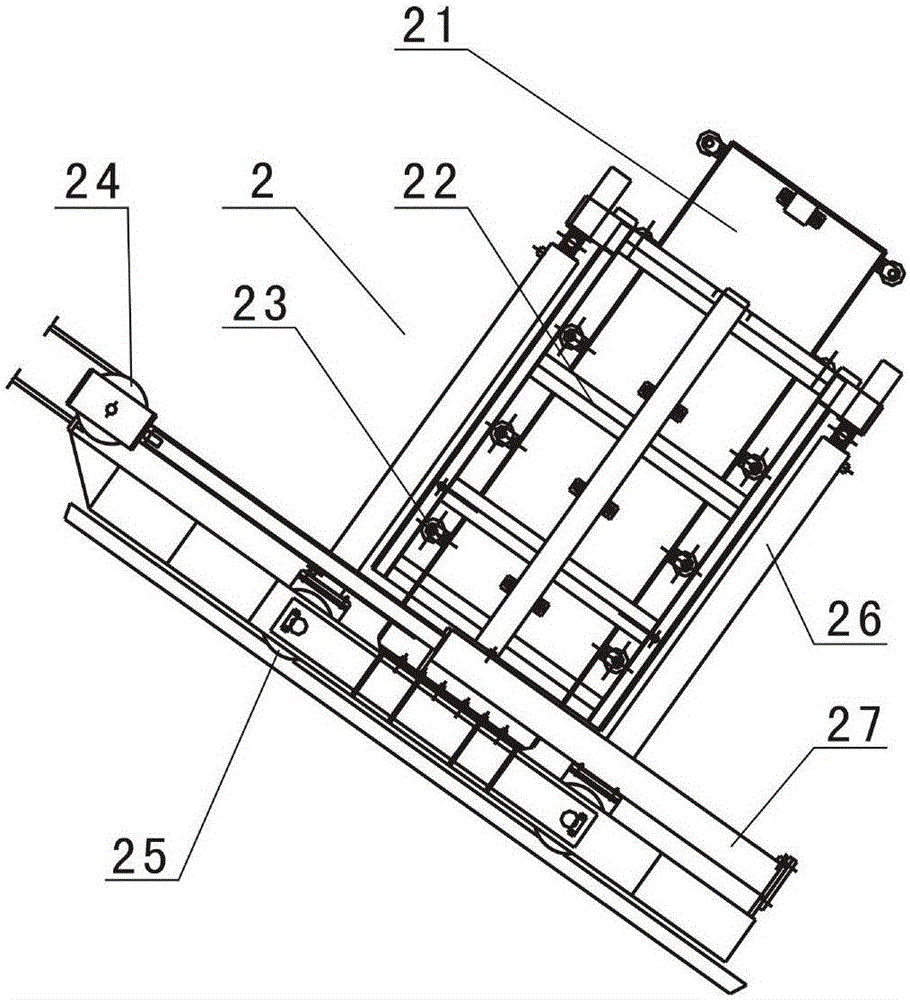

[0052] like figure 1 , figure 2 , Figure 15-Figure 19 As shown, the face panel rockfill dam concrete panel construction full-line section automatic panel repairing machine of the present invention includes the main frame 1 of the truss steel structure, the main frame driving device 2, the repairing hanger 3, the repairing device 4 and the repairing drive Device 5, the main frame 1 is installed on the main frame driving device 2 and can move back and forth and up and down, the two main frame driving devices 2 are respectively installed on the two ends of the main frame 1, and multiple repair hangers 3 are installed on the main frame 1, the wiper device 4 includes a wiper shaft 41 and a wiper blade 42, and the front and rear (with the travel direction of the wiper machine as the front) two sets of wiper shafts 41 are installed on the wiper hanger 3 respectively Driven an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com