Aflatoxin online detection device and material sorting equipment using the device

An aflatoxin and detection device technology, which is applied in the field of aflatoxin sorting devices, can solve the problems of weak fluorescence signal, weak fluorescence wavelength characteristics, poor recognition rate, etc., achieves wide application prospects and improves online recognition. rate, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

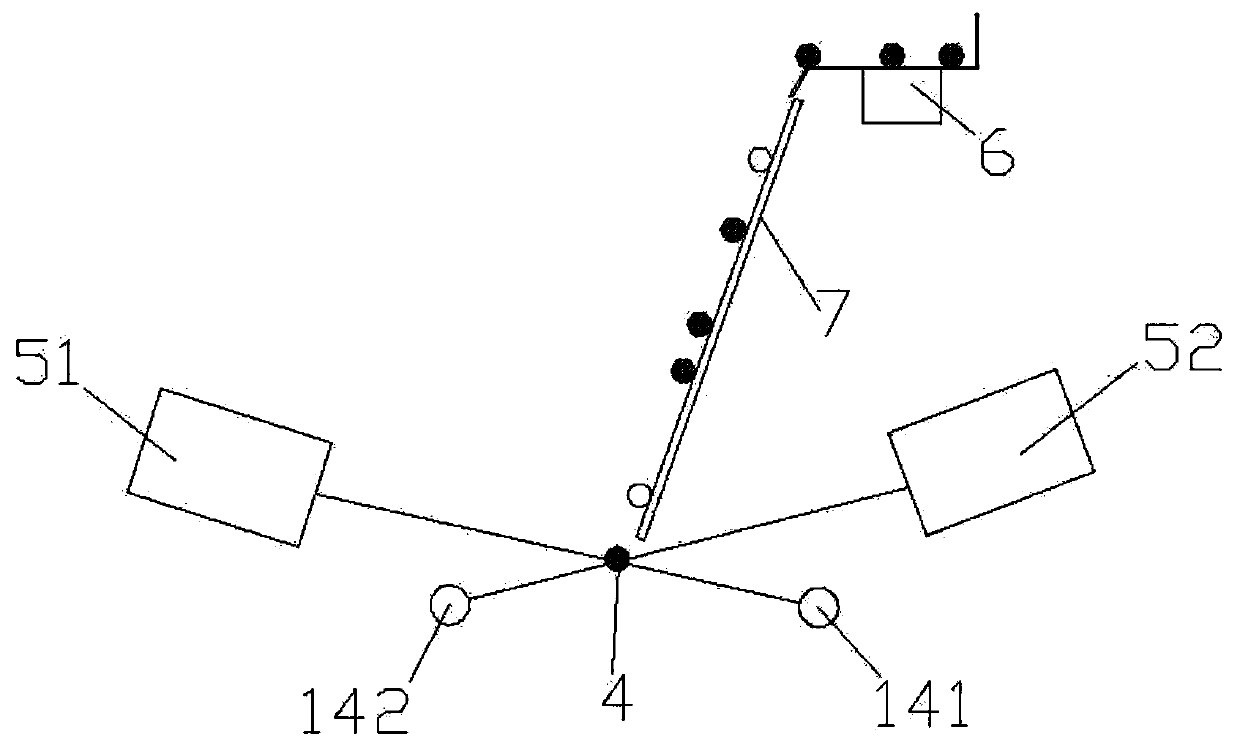

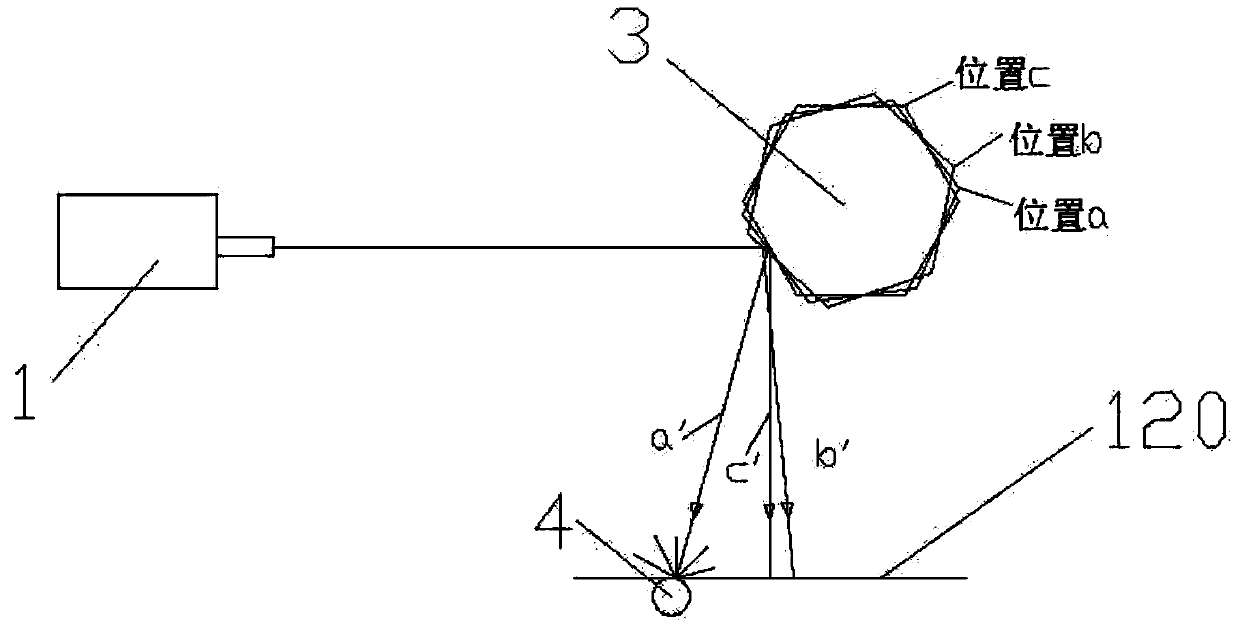

[0031] Please refer to figure 1 , The aflatoxin online detection device of this embodiment includes two light source emitting and signal receiving integrated units 51 and 52 distributed symmetrically or asymmetrically on both sides of the track of the material 4 . The material 4 enters the material conveying unit 7 from the unloading device 6 and is transported to the detection areas of the light emitting and signal receiving integrated units 51 and 52 with the same structure.

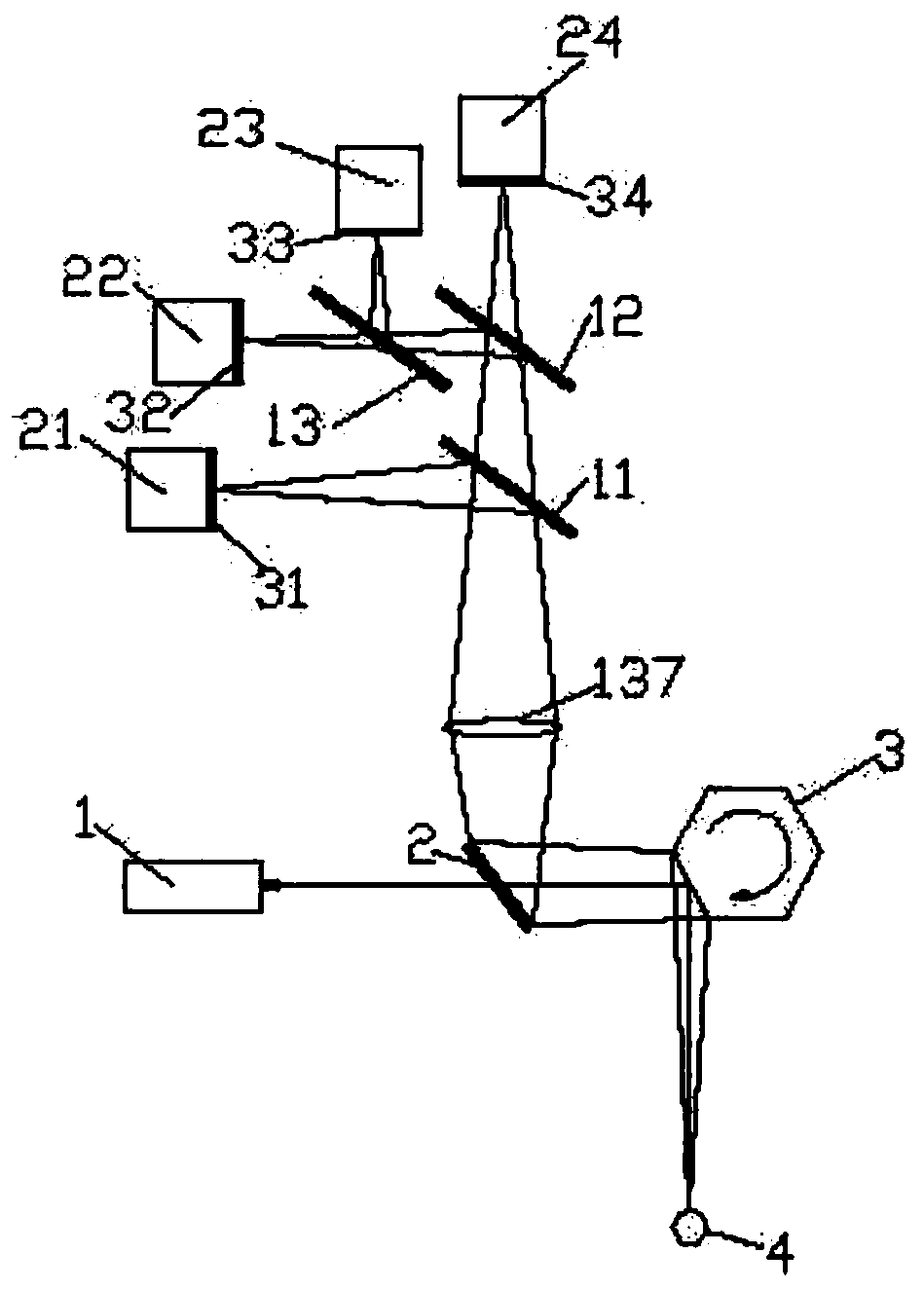

[0032] Please also see figure 2 As shown, each light source emission and signal reception integrated unit includes an ultraviolet light source 1, a hole mirror 2, a rotating mirror 3, an imaging lens 4, spectroscopic filters 11, 12, 13, and single-point photodetectors 21, 22 ,twenty three.

[0033] The ultraviolet light source 1 and single-point photodetectors 21 , 22 , 23 in each group of integrated light source emitting and signal receiving units are arranged oppositely on both sides of the track...

no. 2 example

[0045] This patent application can also design another structure of aflatoxin online detection device according to the structural principle diagram of another embodiment. The method is to use a spectroscopic filter to perform light splitting first, and install multiple imaging lenses and corresponding multiple single-point photodetectors.

[0046] see Figure 4 In this embodiment, the light source emitting and signal receiving integrated unit on the side of the material 4 includes an illumination system 71 , spectroscopic filters 14 , 15 , imaging lenses 131 , 132 , 133 , and single-point photodetectors 81 , 82 , 83 . The light emitting and signal receiving integrated unit structure on the other side of the material 4 includes an illumination system 72 , spectroscopic filters 16 , 17 , imaging lenses 134 , 135 , 136 , and single-point photodetectors 84 , 85 , 86 .

[0047] Usually, fluorescence characteristic filters 91-96 need to be added between the imaging lenses 131-136 a...

no. 3 example

[0053] This patent application can also be according to the structural schematic diagram of another embodiment ( Figure 7 ) designed another structure of aflatoxin on-line detection device, the difference between its signal receiving mode and the second embodiment is that there is no spectroscopic filter, and multiple imaging lenses plus corresponding multiple single-point photodetectors are directly used way to achieve.

[0054] see Figure 7 In this embodiment, the integrated unit for light source emission and signal reception on the side of the material 4 includes an illumination system 71 , imaging lenses 131 , 132 , 133 , and single-point photodetectors 81 , 82 , 83 . The light emitting and signal receiving integrated unit structure on the other side of the material 4 includes an illumination system 72 , imaging lenses 134 , 135 , 136 , and single-point photodetectors 84 , 85 , 86 .

[0055] Usually, fluorescence characteristic filters 91-96 need to be added between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com