Laser fluorescence inspection method for recognizing sequence of crossed writing and seal stamp

A fluorescence inspection and laser technology, which is applied in the field of laser fluorescence inspection, can solve the problems of misjudgment, damage to inspection materials, and failure to apply, etc., and achieve the effect of simple method and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Choose laser equipment

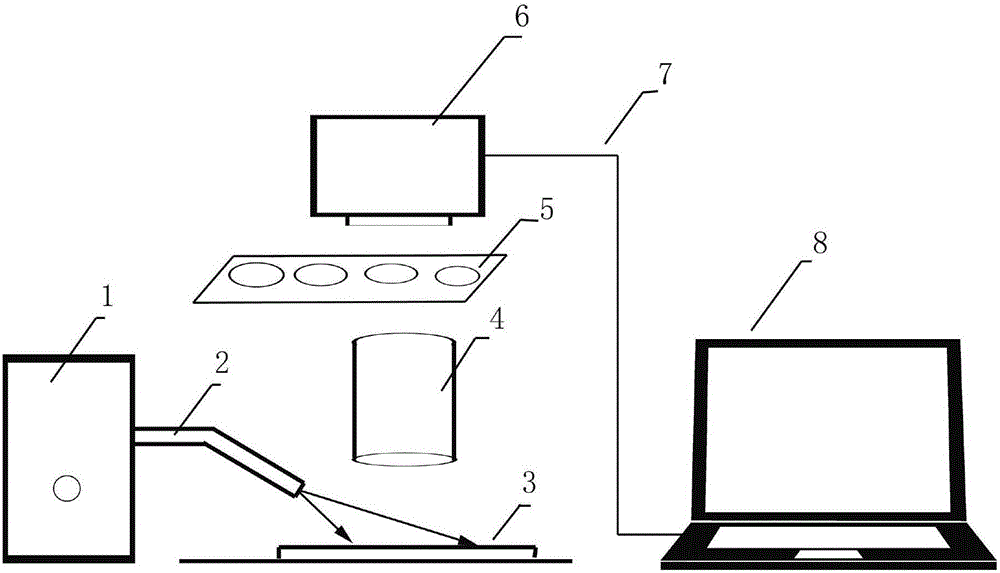

[0025] see figure 1 , The laser visible beam color wavelength from short to long is: blue-violet (405nm), blue (445nm, 460nm, 473nm), green (532nm), yellow (589nm) and red (635nm, 650nm). Since most printing inks have the strongest fluorescence excited by blue excitation light with a wavelength of 445nm-473nm, and commonly used writing colorants have no fluorescence in this band, so a blue diode laser or pump laser with a wavelength of 445nm or 473nm is selected 1 is used as a light source, and the laser beam is expanded by a beam expander or an optical fiber beam expander 2. One of the purposes is to expand the observation area, and the other is to reduce the illumination temperature: it does not cause damage to the paper or ink coloring material of the inspection material 3. Under the premise of destruction, the temperature of the general inspection material paper should not exceed 70°C when it is irradiated to obtain the maximum light int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com