Multi-friction plate superimposed loading mechanism and a large-value bidirectional friction-loaded electro-hydraulic load simulator using this mechanism

A multi-friction plate and loading mechanism technology, applied in simulators, instruments, general control systems, etc., to achieve high-frequency response and high-dynamic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

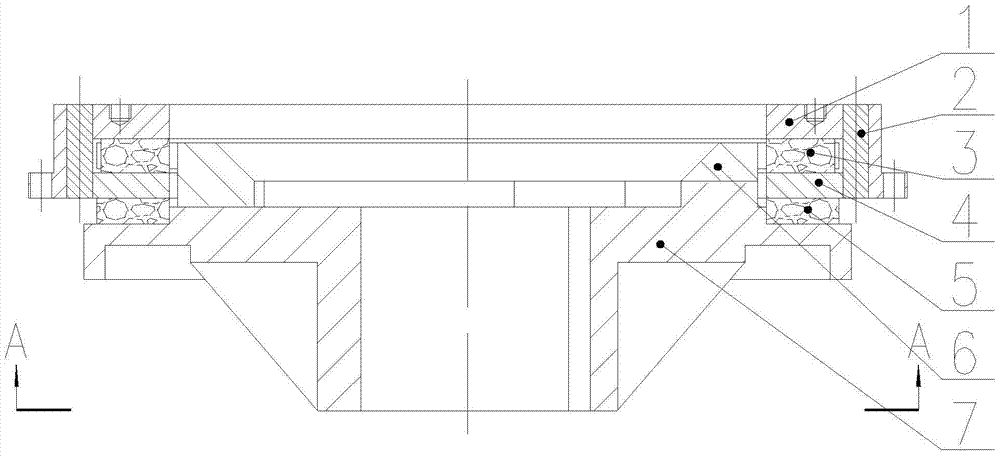

[0026] Specific implementation mode one: the following combination Figure 3 to Figure 7 Describe this embodiment, the multi-friction plate superposition loading mechanism described in this embodiment includes a first constant rotation friction plate 1, six pins 2, a second swing friction plate 3, a second constant rotation friction plate 4, a first swing Friction plate 5, second friction plate support 6 and first friction plate support 7;

[0027] The first friction plate support 7 is fixed on the main shaft 40 through a sliding key 8, and a first swinging friction plate 5 is fixed on the side surface of the first friction plate support 7;

[0028] The first friction plate support 7 is correspondingly and fixedly connected with the second friction plate support 6 through a concave-convex groove, and the second friction plate support 6 and the first friction plate support 7 swing together and transmit torque to the main shaft 40;

[0029] The second swinging friction plate 3 ...

specific Embodiment approach 2

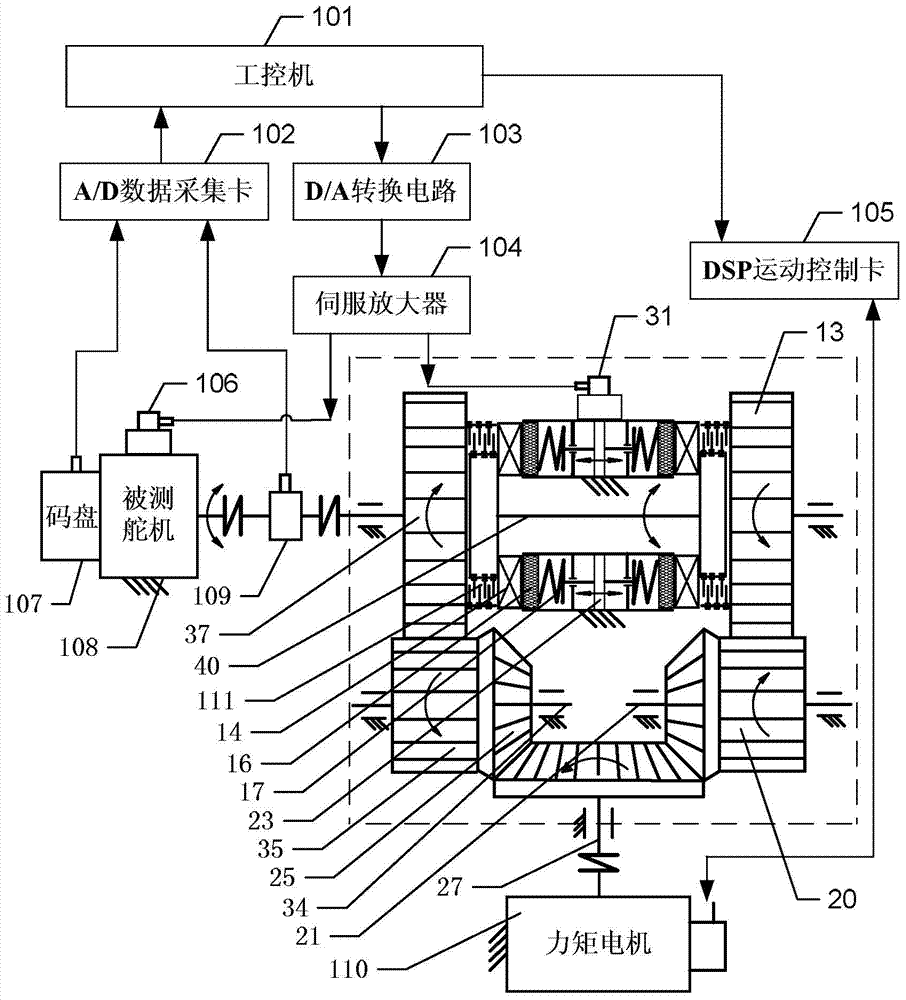

[0034] Specific implementation mode two: the following combination Figure 1 to Figure 9 Describe this embodiment mode, this embodiment mode adopts multi-friction plate superposition loading mechanism described in the present invention to use the large value two-way friction loading type electro-hydraulic load simulator, it comprises industrial computer 101, A / D data acquisition card 102, D / A converter Circuit 103, servo amplifier 104, DSP motion control card 105, large servo valve 106, code disc 107, torque sensor 109, torque motor 110 and load simulation unit;

[0035] The code disc 107 and the large servo valve 106 are arranged on the steering gear 108 under test; the steering gear 108 under test is rigidly connected with the main shaft 40 through a torque sensor 109; The input end is connected, and the signal output end of torque sensor 109 is connected with the second input end of A / D data acquisition card 102, and the output end of A / D data acquisition card 102 is connec...

specific Embodiment approach 3

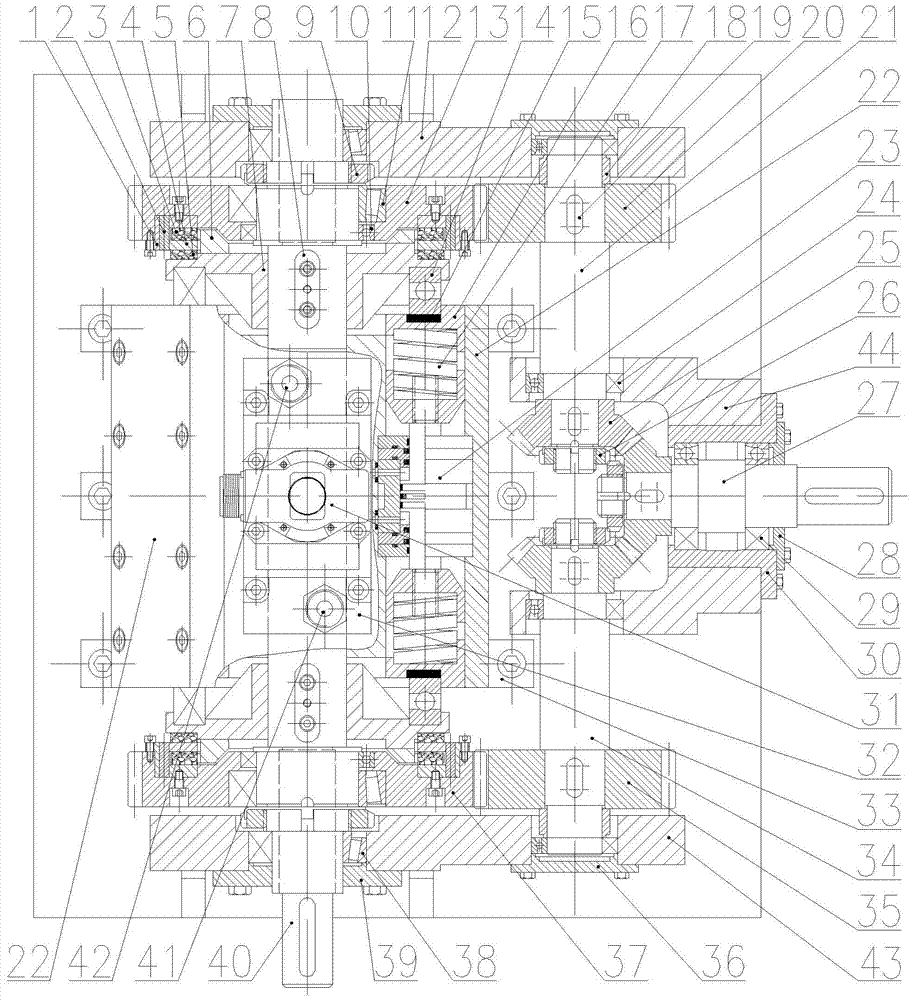

[0050] Embodiment 3: This embodiment is a further limitation of Embodiment 2. The load simulation unit also includes two first round nuts 9, a second round nut 26, two first bearings 10, two second bearings 11, Two third bearings 24, fourth bearings 29, two fifth bearings 38, upper base 12, lower base 43, middle base 44, first large gear 13, second large gear 37, sleeve 18, Key 19, first pinion gear 20, second pinion gear 35, A transmission shaft 27, No. 1 B transmission shaft 21, No. 2 B transmission shaft 34, hydraulic cylinder cover plate 22, three bevel gears 25, first bearing end Cover 28, second bearing end cover 36, two third bearing end covers 39, bearing sleeve 30, valve block 32, hydraulic cylinder support 33, main shaft 40, oil outlet 41 and oil inlet 42; upper base 12. The lower base 43 and the middle base 44 are integrated;

[0051] A bevel gear 25 is connected together with the A transmission shaft 27 through a key, and the No. 1 B transmission shaft 21 is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com