A transmission for an electric vehicle

A technology of electric vehicles and transmissions, applied in electric vehicles, electric components, electromechanical transmissions, etc., can solve the problems of high price, poor speed regulation performance of AC induction motors, and unsatisfactory performance, and achieve good speed regulation, compact structure, and good performance. The effect of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

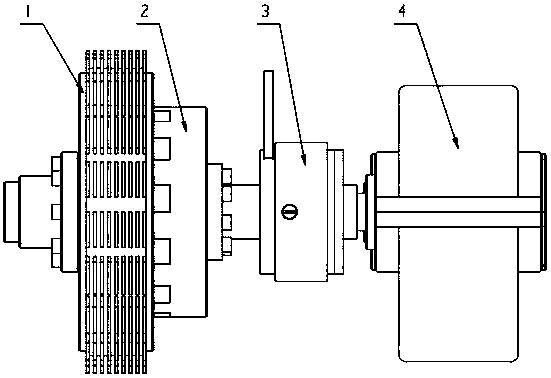

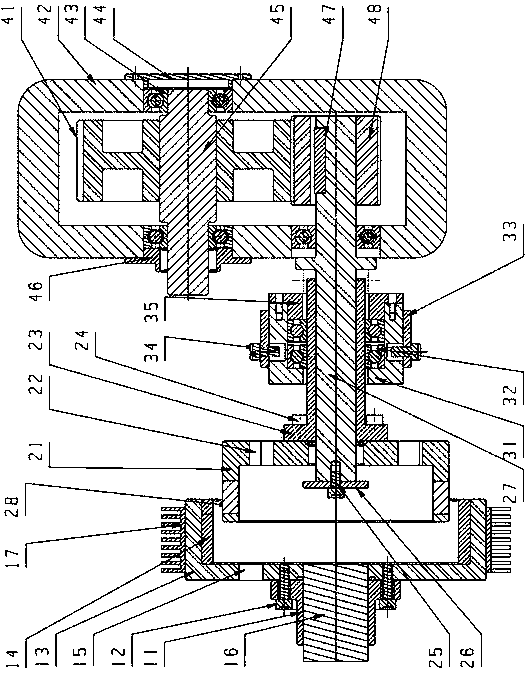

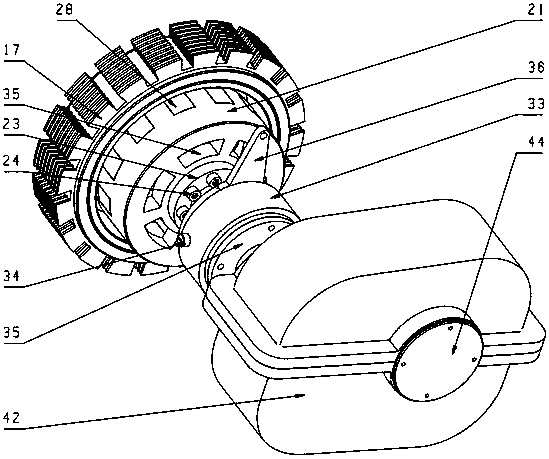

[0016] The structure diagram of the present invention is as figure 1 , 2 , 3, the electric vehicle transmission of the present invention includes a permanent magnet speed regulating part and a reduction box 4, and the permanent magnet speed regulating part includes a cylindrical conductor rotor 1, a cylindrical permanent magnet rotor 2 and a speed regulating mechanism 3 three Part, the main body of the cylindrical conductor rotor 1 includes a conductor drum 13, an inner conductor 14 and an active flange 11, wherein the conductor drum 13 is connected to the input shaft 16 through the active flange 11, and the active flange 11 is set on the input shaft 16, and the active flange 11 is connected to the conductor drum 13, the inner wall of the conductor drum 13 is provided with a layer of inner conductor 14, the main body of the cylindrical permanent magnet rotor 2 includes a permanent magnet drum 21, a permanent magnet 28 And the driven flange 23, wherein one end of the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com