Soft start and closed-loop control method of pulse generating circuit

A technology for generating circuits and closed-loop control, applied in electrical components, output power conversion devices, etc., can solve the problems of reducing the dust collection area, limitation, and lack of practicality of the dust collector, and achieve increased stability and anti-interference ability. The effect of avoiding shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

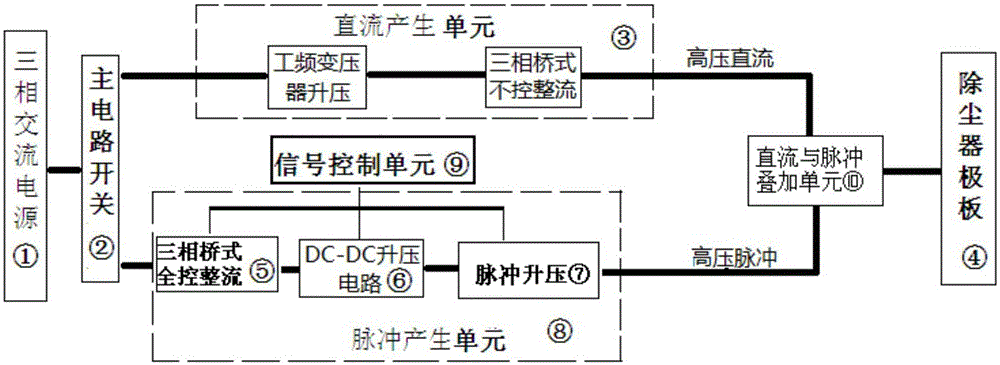

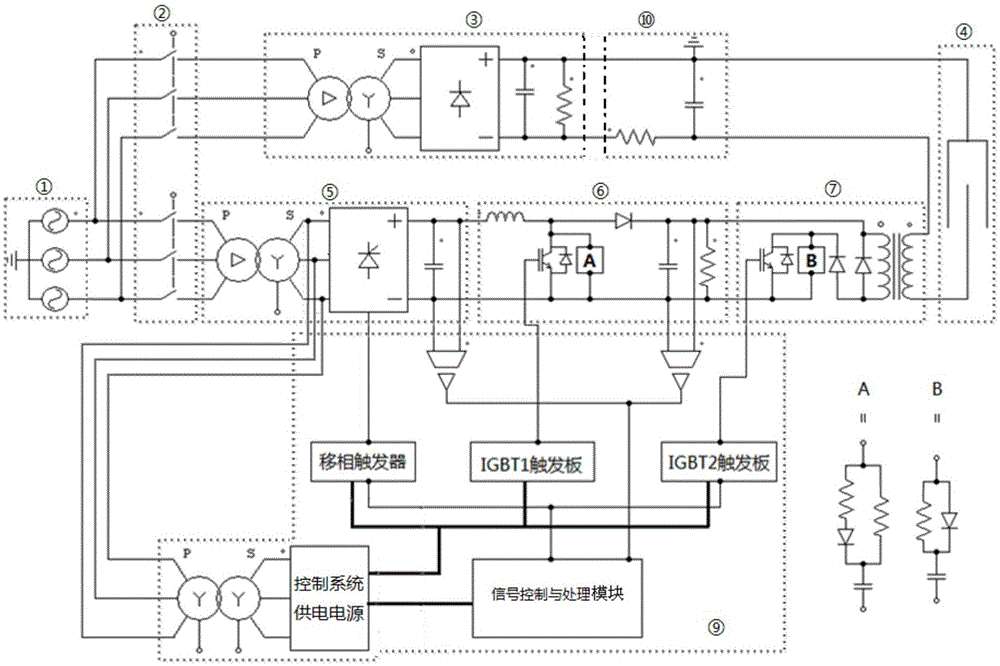

[0021] Such as figure 2 As shown, a DC pulse power supply scheme for electrostatic precipitator, the designed power supply includes a main circuit switch ② connected to the three-phase AC power ①, a DC generating unit ③ connected to the main circuit switch and a pulse generating unit ⑧ , the pulse generation unit is connected to a signal control unit ⑨, the output of the DC generation unit and the pulse generation unit is connected to the dust collector plate ④ through a DC and pulse superposition unit ⑩. Among them, the DC generation unit is composed of a power frequency transformer step-up module and a three-phase bridge uncontrolled rectification module in series; the pulse generation unit is sequentially composed of a three-phase bridge full-control rectification module ⑤, a DC-DC step-up circuit ⑥, a pulse step-up Module ⑦ constitutes. After the three-phase AC power supply is switched by the main circuit, one path is boosted and rectified by the DC generating unit to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com