Heat-resistant austenitic stainless steel sheet

An austenitic, stainless steel plate technology, used in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problem of no stainless steel plates, and achieve the effects of excellent oxidation resistance, excellent workability, and excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

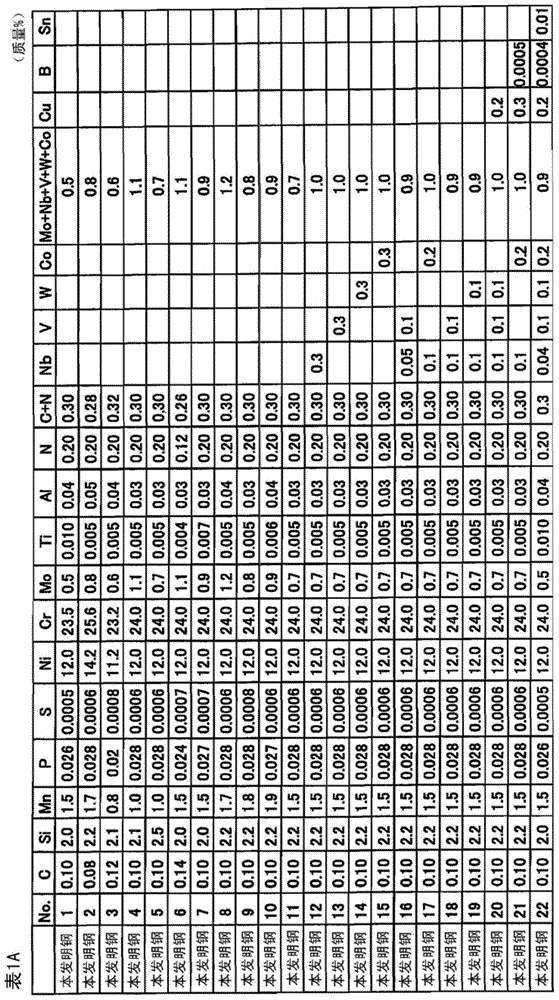

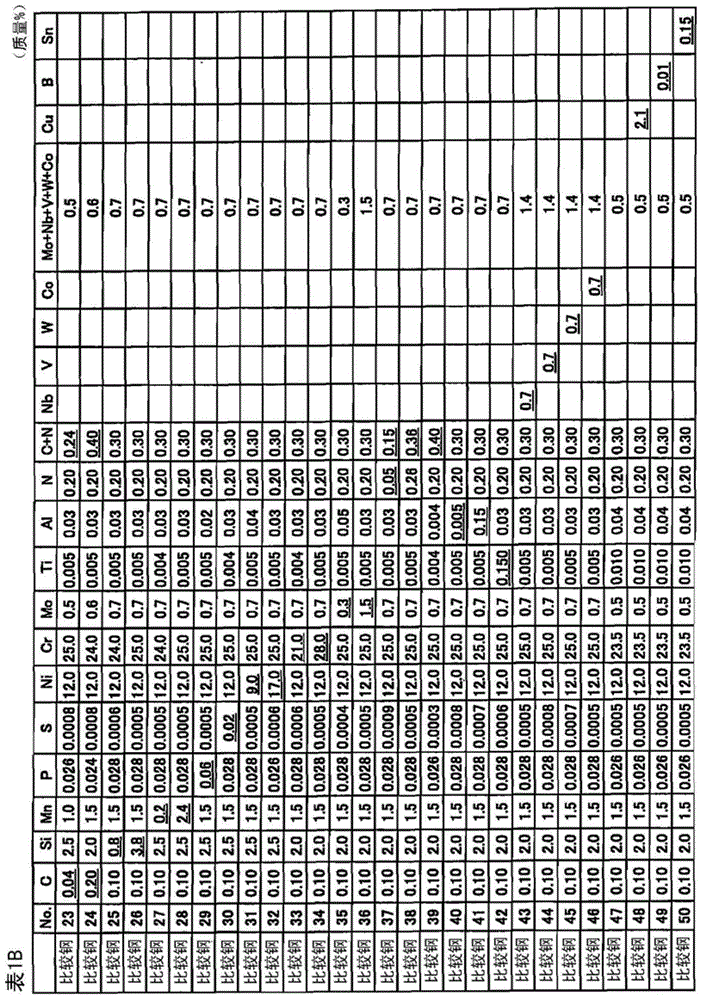

[0066] In this example, first, steel having the composition shown in Table 1A and Table 1B was melted and cast into a slab. After the slab is heated to 1150 to 1250°C, the finishing temperature is set in the range of 850 to 950°C and hot rolled to a thickness of 3 to 5 mm. Then, they were annealed at 1000 to 1200°C, cold rolled to 1.5 mm after pickling, and then annealed and pickled at 1000°C to 1200°C as the test steel. In Table 1A and Table 1B, values that deviate from the scope of the present invention are underlined.

[0067] The cold-rolled and annealed sheets obtained in this way were subjected to tensile tests and intermittent oxidation tests at room temperature and high temperature. Tensile test at room temperature is used to evaluate workability. According to JISZ2201 (corresponding to the international standard: ISO6892, 1984), JIS13B test pieces with the direction parallel to the rolling direction as the length direction are used, according to JISZ2241 (correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com