Spun yarn and woven or knitted fabric

A fiber and flat technology, applied in the field of woven fabrics, can solve the problems of insufficient water absorption and soft hand feeling, insufficient impermeability, etc., and achieve the effect of excellent water absorption and high impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

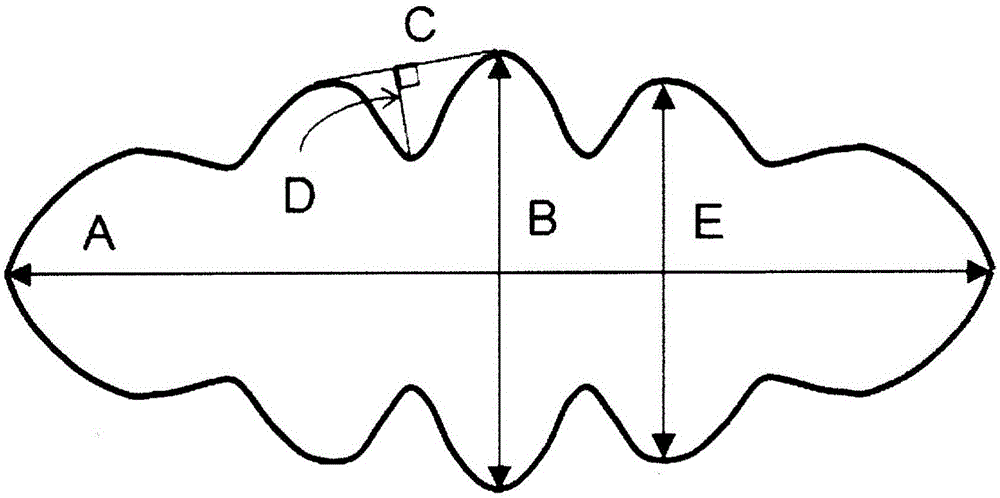

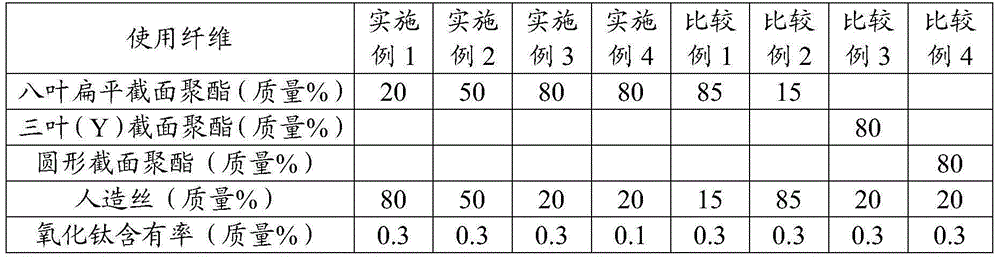

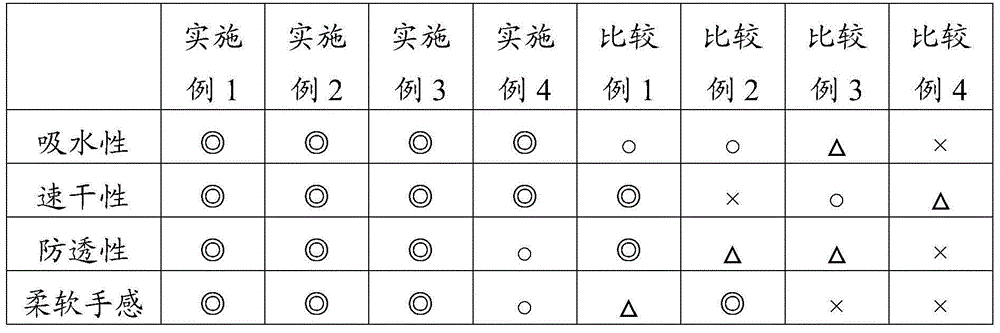

[0093] A flat multi-lobed cross-section polyester system with a single fiber fineness of 1.7 dtex, a titanium oxide content of 0.3% by mass, a flatness of 2.1, a degree of irregularity of 2.7, a protrusion ratio of 0.8, and a cross-sectional shape of 8 protrusions Fiber (fiber length 51mm) 20% by mass and rayon fiber (fiber length 51mm) with a single fiber fineness of 1.7dtex 80% by mass were blended to obtain a spun yarn with an English cotton count of 40s with a twist coefficient K = 3.5 . This spun yarn was used for warp and weft, and a flat fabric having a warp density of 110 threads / 2.54 cm and a weft density of 76 threads / 2.54 cm was obtained using an air-jet loom. Table 1 shows the fiber configuration of the spun yarn, and Table 2 shows the evaluation results.

Embodiment 2

[0095] A flat multi-lobed cross-section polyester system with a single fiber fineness of 1.7 dtex, a titanium oxide content of 0.3% by mass, a flatness of 2.1, a degree of irregularity of 2.7, a protrusion ratio of 0.8, and a cross-sectional shape of 8 protrusions 50% by mass of fiber (fiber length: 51 mm) and 50% by mass of rayon fiber (fiber length: 51 mm) having a single fiber fineness of 1.7 dtex were blended to obtain a spun yarn with an English cotton count of 40 s with a twist coefficient K = 3.5 . This spun yarn was used for warp and weft, and a flat fabric having a warp density of 110 threads / 2.54 cm and a weft density of 76 threads / 2.54 cm was obtained using an air-jet loom. Table 1 shows the fiber configuration of the spun yarn, and Table 2 shows the evaluation results.

Embodiment 3

[0097] A flat multi-lobed cross-section polyester system with a single fiber fineness of 1.7 dtex, a titanium oxide content of 0.3% by mass, a flatness of 2.1, a degree of irregularity of 2.7, a protrusion ratio of 0.8, and a cross-sectional shape of 8 protrusions Fiber (fiber length 51mm) 80% by mass and rayon fiber (fiber length 51mm) with a single fiber fineness of 1.7dtex 20% by mass were blended to obtain a spun yarn with an English cotton count of 40s at a twist coefficient K = 3.5 . This spun yarn was used for warp and weft, and a flat fabric having a warp density of 110 threads / 2.54 cm and a weft density of 76 threads / 2.54 cm was obtained using an air-jet loom. Table 1 shows the fiber configuration of the spun yarn, and Table 2 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irregularity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com