Saline-alkali paddy salt-leaching and salt-removing method

A technology for paddy field and salt washing, which is applied to the field of salt washing and salt discharge in saline-alkali paddy fields, can solve the problems of long preparation time for field cultivation, large fresh water consumption, and many times of salt washing, and achieves reduction of fresh water consumption, fast salt washing, Good effect of washing salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

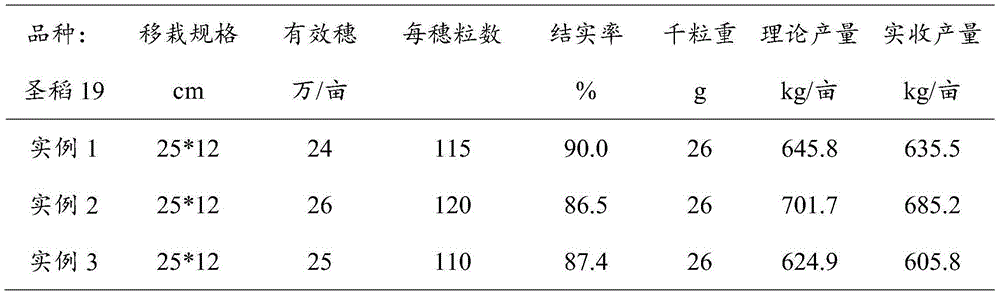

Embodiment 1

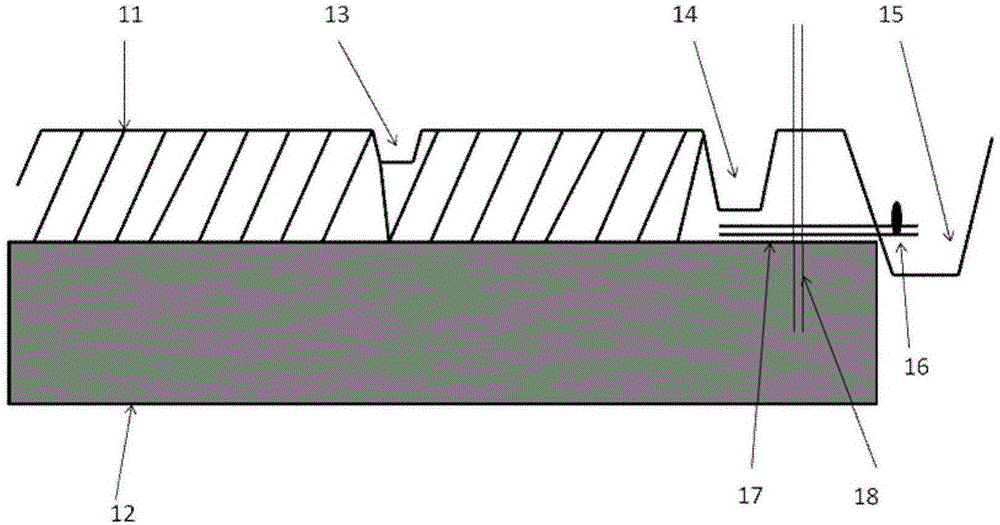

[0018] During the process of finishing the saline-alkali land into rice fields, buried salt drainage pipes are embedded every 5m at the bottom of the saline-alkali land cultivation layer for salt drainage. Valves are arranged on the salt drainage pipes, and the outlet of the salt drainage pipes communicates with the drainage ditch. Groundwater level measuring pipes are installed every 10m in the field ridges to monitor the groundwater level.

[0019] Deep plowing was carried out 10 days before transplanting rice. After deep plowing, pour fresh water into it to make the fresh water 2cm higher than the field surface, and then carry out rotary tillage to increase the contact surface between soil and fresh water, so that fresh water can fully contact with soil particles, increase the speed of salt washing and reduce the consumption of fresh water. Drain the fresh water after soaking the field for 1 day, and continue to pour in fresh water to make the fresh water 2cm higher than th...

Embodiment 2

[0023] During the process of finishing the saline-alkali land into rice fields, buried salt drainage pipes are embedded every 5m at the bottom of the saline-alkali land cultivation layer for salt drainage. Valves are arranged on the salt drainage pipes, and the outlet of the salt drainage pipes communicates with the drainage ditch. Groundwater level measuring pipes are installed every 10m in the field ridges to monitor the groundwater level.

[0024] Deep plowing was carried out 7 days before transplanting rice. After deep plowing, pour fresh water into it to make the fresh water 2cm higher than the field surface, and then carry out rotary tillage to increase the contact surface between soil and fresh water, so that fresh water can fully contact with soil particles, increase the speed of salt washing and reduce the consumption of fresh water. Drain the fresh water after soaking the field for 1 day, and continue to pour in fresh water to make the fresh water 2cm higher than the...

Embodiment 3

[0028] During the process of finishing the saline-alkali land into rice fields, buried salt drainage pipes are embedded every 5m at the bottom of the saline-alkali land cultivation layer for salt drainage. Valves are arranged on the salt drainage pipes, and the outlet of the salt drainage pipes communicates with the drainage ditch. Groundwater level measuring pipes are installed every 10m in the field ridges to monitor the groundwater level.

[0029] Deep plowing was carried out 5 days before transplanting rice. After deep plowing, pour fresh water into it to make the fresh water 4cm higher than the field surface, and then carry out rotary tillage to increase the contact surface between soil and fresh water, so that fresh water can fully contact with soil particles, increase the speed of salt washing and reduce the amount of fresh water. After 2 days of soaking in the field, drain fresh water, continue to pour in fresh water to make the fresh water 4cm higher than the field su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com