Preparation method and application of plant source complex preservative

A compound fresh-keeping and extract technology, which is applied in the field of preparation of plant-derived compound preservatives, can solve problems such as toxic and side effects, and achieve stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

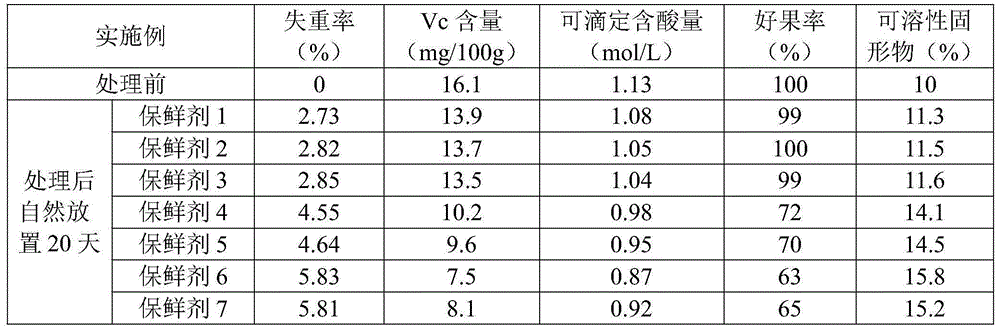

[0061] Embodiment 1: the making of composite antistaling agent

[0062] (1) Add 1.5g sodium alginate to 500mL water to prepare a sodium alginate solution, add 3.8g gelatin, 3.8g carrageenan and 3.8g xanthan gum to the sodium alginate solution and mix to form a sol;

[0063] (2) Add 20g Chrysanthemum chrysanthemum flavonoids extract and 20g Mountain Silver Flower polyphenol extract to 500mL water to make a mixed extract, then add 0.4g radish lysozyme and 0.4g barley lysozyme to continue mixing to form a mixed solution ;

[0064] (3) The above mixed solution was added dropwise to the sol in step (1) at a speed of 0.8 mL / s under the action of mechanical stirring and mixed to obtain the composite preservative 1.

Embodiment 2

[0065] Embodiment 2: the making of composite antistaling agent

[0066] (1) Add 1.5g sodium alginate to 500mL water to prepare a sodium alginate solution, add 3.8g gelatin, 3.8g carrageenan and 3.8g xanthan gum to the sodium alginate solution and mix to form a sol;

[0067] (2) Add 15g of Chrysanthemum chrysanthemum flavonoids extract and 25g of Alba japonica polyphenols extract to 500mL of water to make a mixed extract, then add 0.4g of radish lysozyme and 0.4g of barley lysozyme to continue mixing to form a mixed solution ;

[0068] (3) Add the above-mentioned mixed solution dropwise to the sol in step (1) at a rate of 0.8 mL / s under mechanical stirring, and mix to obtain the composite preservative 2.

Embodiment 3

[0069] Embodiment 3: the making of composite antistaling agent

[0070] (1) Add 1.5g sodium alginate to 500mL water to prepare a sodium alginate solution, add 3.8g gelatin, 3.8g carrageenan and 3.8g xanthan gum to the sodium alginate solution and mix to form a sol;

[0071] (2) Add 25g of Chrysanthemum chrysanthemum flavonoids extract and 15g of Alba japonica polyphenols extract to 500mL water to make a mixed extract, then add 0.4g of radish lysozyme and 0.4g of barley lysozyme to continue mixing to form a mixed solution ;

[0072] (3) The above mixed solution was added dropwise to the sol in step (1) at a speed of 0.8mL / s under the action of mechanical stirring, and mixed to obtain the composite preservative 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com