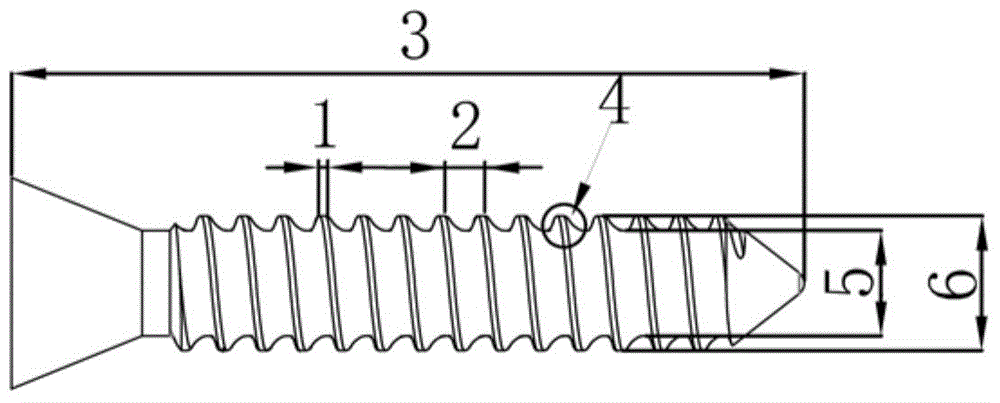

Directionally degradable and absorbable magnesium bone screw and preparation method thereof

A technology of bone screw and magnesium metal, applied in the field of magnesium metal bone screw and its preparation, can solve the problems of poor bonding force, easy falling off, complicated coating technology and process, and achieve the effect of ensuring integrity and maintaining early tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

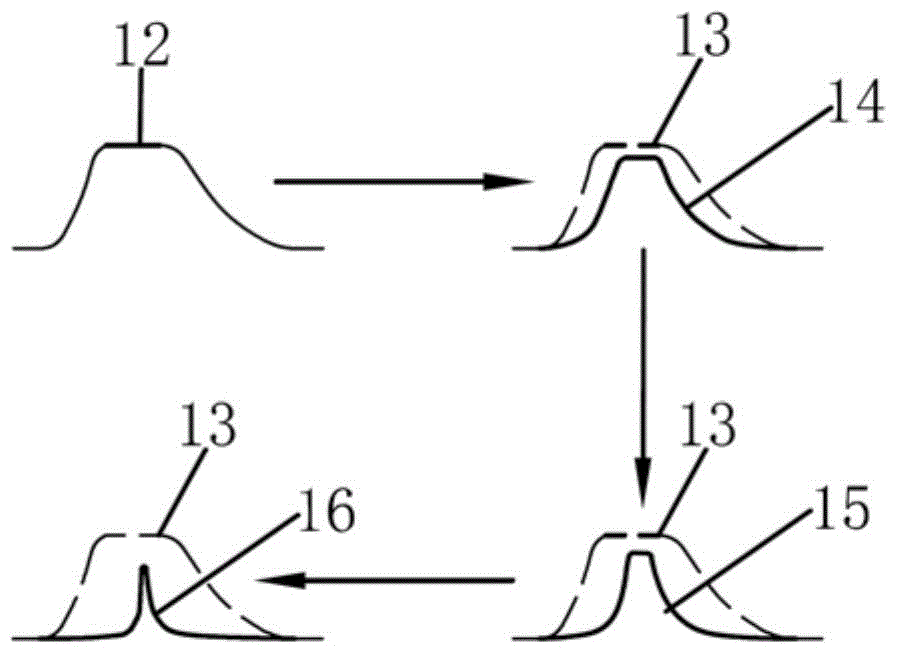

[0042] More than 99.98% pure magnesium ingot is used to extrude into rods at 100°C, the extrusion ratio is 20, the extruded rods are discharged at a speed of 20mm / min, the taper of the discharge port is 180°, and there is no lubrication. XRD analysis was carried out on the extruded rod, and it was found that the (10-11) crystal plane had the strongest diffraction peak in the cross section of the extruded rod, and the (10-11) crystal plane had the strongest diffraction peak on the longitudinal section, as shown in Figure 6 Shown in (a) and (b) parts.

[0043] Afterwards, the above-mentioned pure magnesium hot extruded rod is subjected to further cold extrusion at an extrusion temperature of 80° C., and the cross-sectional area of the rod after extrusion is reduced to 95% of its original value. Further analysis by XRD found that the intensity of the diffraction peaks of the (10-10) and (0002) crystal planes in the cross-section of the bar after cold working was significantly ...

Embodiment 2

[0048] The Mg-5.4Zn alloy is used to extrude into rods at 300° C., the extrusion ratio is 60, and the extrusion speed of the rods is 10 mm / min. According to the XRD analysis of the extruded rod, it is found that the (10-11) crystal plane diffraction peak is the strongest in the cross section of the extruded rod, and the (10-11) crystal plane diffraction peak is also the strongest in the longitudinal section.

[0049] Afterwards, the above-mentioned extruded bar is further cold-rolled at a rolling temperature of 40° C., and the cross-sectional area of the bar is reduced to 50% of the original after rolling. Further analysis by XRD found that the intensity of the diffraction peaks of the (10-10) and (0002) crystal planes in the cross-section of the rolled bar increased, and the intensity was 60% of that of the (10-11) crystal plane, but still lower than that of the (10-10) crystal plane. -11) Plane strength, that is, the (10-11) crystal plane has a dominant orientation on the ...

Embodiment 3

[0054] Mg-0.8Mn-1Zn alloy is used, extruded into rods at 500°C, the extrusion ratio is 100, the extruded rods are discharged at a speed of 5mm / min, the taper of the discharge port is 170°, and there is no lubrication. According to the XRD analysis of the extruded rod, it is found that the (10-11) crystal plane diffraction peak is the strongest in the cross section of the extruded rod, and the (10-11) crystal plane diffraction peak is also the strongest in the longitudinal section.

[0055] Afterwards, the above-mentioned extruded rods are further cold-extruded at a room temperature of 25° C., and the cross-sectional area of the rods is reduced to 40% of the original after extrusion. Further analysis by XRD found that the intensity of the diffraction peaks of the (10-10) and (0002) crystal planes in the cross-section of the rod after cold extrusion increased, and the intensity was 55% of that of the (10-11) crystal plane, but still lower than ( 10-11) plane strength, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com