Desulfurization, denitrification, mercury removal and dust removal integrated flue gas purifier

A desulfurization, denitrification, and purifier technology, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of increased operating costs, inability to desulfurize and denitrify, and high operating costs, and can solve the problem of water carrying and serious blockage of fans, Ensure high efficiency and rationality, improve the effect of purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

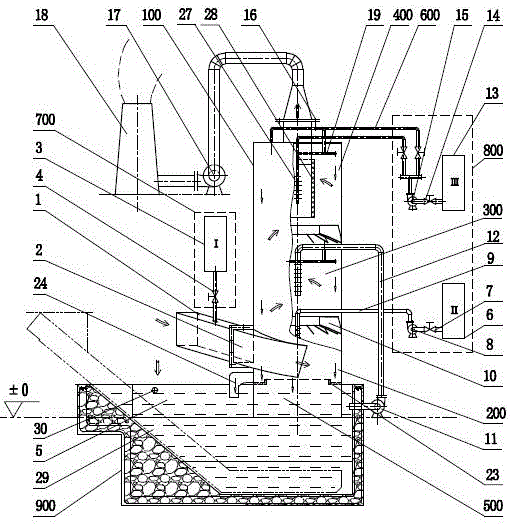

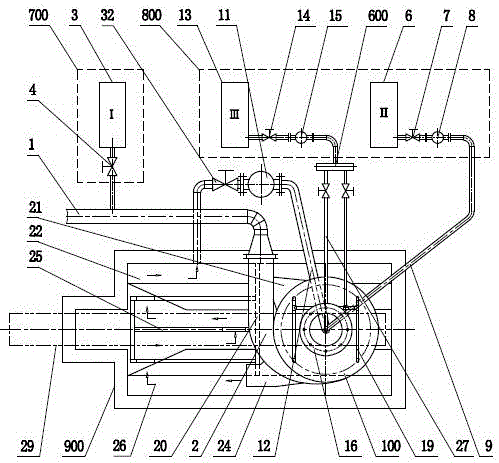

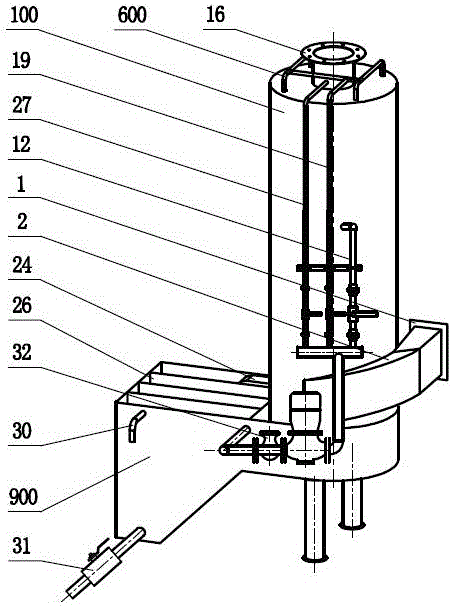

[0027] Such as figure 1 , figure 2 As shown, an integrated flue gas purifier for desulfurization, denitrification, mercury removal and dust removal, the purifier includes an integrated purification tower 100 in the form of a hollow cylinder placed on a base base 900, connected to the lower part of the integrated purification tower 100 and equipped with a flue gas purifier. The swirling smoke duct 2 of the air inlet 1, the dry absorption and purification agent application device 700, and the wet absorption and purification agent application device 800.

[0028] The base base 900 is equipped with an automatic slag remover 29 and a flocculation and sedimentation purification work area 500 filled with alkaline water body 5, as well as an inner sedimentation circulation area 21 and an outer sedimentation circulation area 500 separated by a vertical partition 20. Area 22 ; the base base 900 where the flocculation and sedimentation purification work area 500 is located is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com