A method for preparing nanoscale noble metal-shell magnetic core composite particles by self-assembly

A technology of composite particles and precious metals, which is used in the preparation of microspheres, the magnetic properties of inorganic materials, and the preparation of microcapsules, can solve the problems of unfavorable research on the formation mechanism of composite microspheres, difficult to achieve process controllability and reference to the preparation method of composite particles, etc. The effect of good biocompatibility and chemical stability, good magnetic responsiveness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

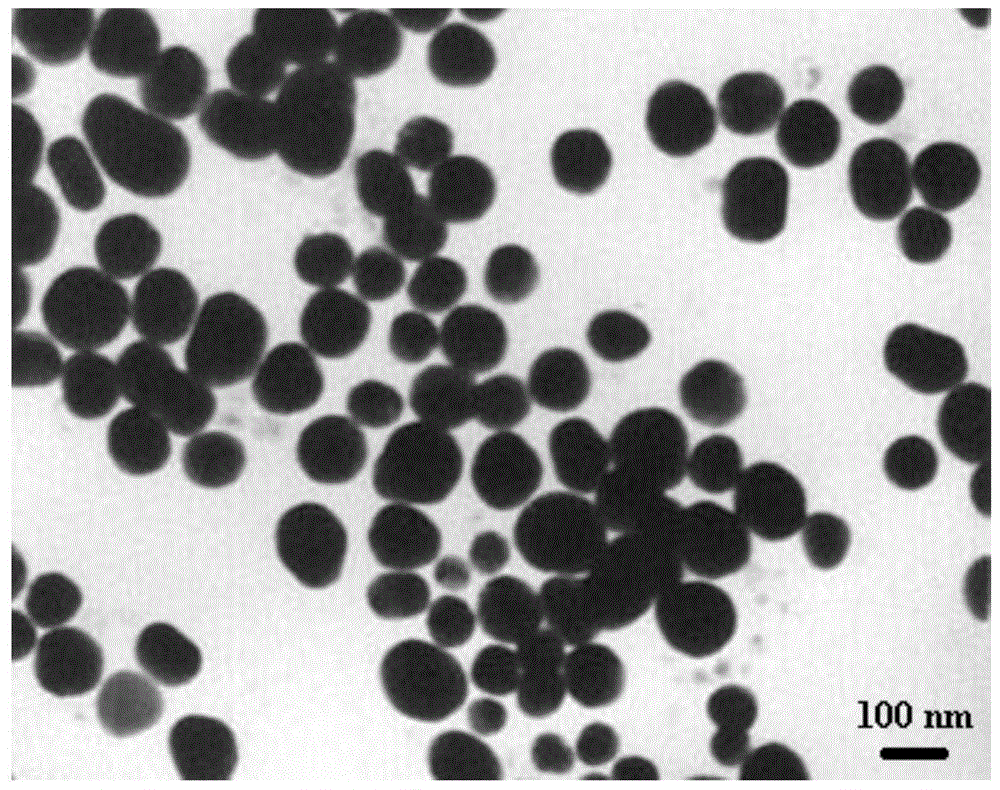

[0036] (1) Fe 3 o 4 Preparation of Nanoparticle Solution:

[0037](a) Add ferrous chloride, 1.5g ferric chloride and sodium oleate into a mixed solvent of ethanol and ethylene glycol in a mass ratio of 2:3:3, stir at room temperature for 1 hour and then add 1mol / L ammonia water Adjust the pH value to 9-10, then transfer the mixed solution to a stainless steel high-pressure reactor, react at 160-190°C for 18 hours, and then centrifuge for 30 minutes to obtain nano-Fe dispersed in the oil phase 3 o 4 , and then washed repeatedly with ethanol and cyclohexane with a volume ratio of 1:1, and then resuspended in cyclohexane to obtain the oil phase nano-Fe 3 o 4 solution;

[0038] (b) Nano-Fe in the oil phase 3 o 4 Add NaClO solution to the solution, and then use 1mol / L NaOH solution to adjust the pH value to 10-11. After stirring, sonicate for 20 minutes to obtain a reaction solution. According to the reaction solution: RuCl 3 The volume ratio is 1:1, add RuCl to the reactio...

Embodiment 2

[0052] (1) Fe 3 o 4 Preparation of Nanoparticle Solution:

[0053] (a) Add ferrous chloride, 1.5g ferric chloride and sodium oleate into the mixed solvent of ethanol and ethylene glycol in a mass ratio of 2:3:3, stir at room temperature for 0.5-1 hour, then add 1mol / L ammonia water to adjust the pH value to 9-10, then transfer the mixed solution to a stainless steel autoclave, react at 160-190°C for 18 hours, and then centrifuge for 30 minutes to obtain nano-Fe dispersed in the oil phase 3 o 4 , and then washed repeatedly with ethanol and cyclohexane with a volume ratio of 1:1, and then resuspended in cyclohexane to obtain the oil phase nano-Fe 3 o 4 solution;

[0054] (b) Nano-Fe in the oil phase 3 o 4 Add NaClO solution to the solution, and then use 1mol / L NaOH solution to adjust the pH value to 10-11. After stirring, sonicate for 20 minutes to obtain a reaction solution. According to the reaction solution: RuCl 3 The volume ratio is 1:1, add RuCl to the reaction so...

Embodiment 3

[0064] A method for preparing nanoscale noble metal-shell magnetic core composite particles by self-assembly, comprising the following steps:

[0065] (1) Fe 3 o 4 Preparation of nanoparticles:

[0066] (a) Add ferrous chloride, ferric chloride and sodium oleate to the mixed solvent of ethanol and ethylene glycol, mix well, use 1mol / L ammonia water to adjust the pH value to 9, and then react at 180°C for 15 Hours, centrifuged to obtain nano-Fe dispersed in the oil phase 3 o 4 , and after washing with a mixture of ethanol and cyclohexane, Fe 3 o 4 Nanoparticles, resuspended in cyclohexane to obtain nano-Fe in oil phase 3 o 4 solution; wherein, the mass ratio of ferrous chloride, ferric chloride, and sodium oleate is 2:3:3.5; the volume ratio of ethanol and ethylene glycol in the mixed solvent of ethanol and ethylene glycol is 1:10; ethanol and The volume ratio of ethanol and cyclohexane in the mixture of cyclohexane is 1:1.

[0067] (b) to the oil phase nano-Fe 3 o 4...

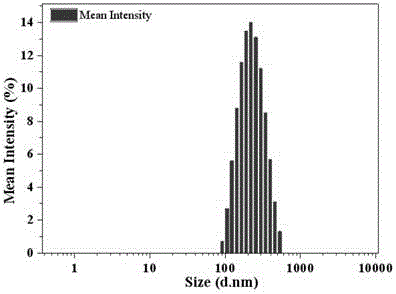

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com