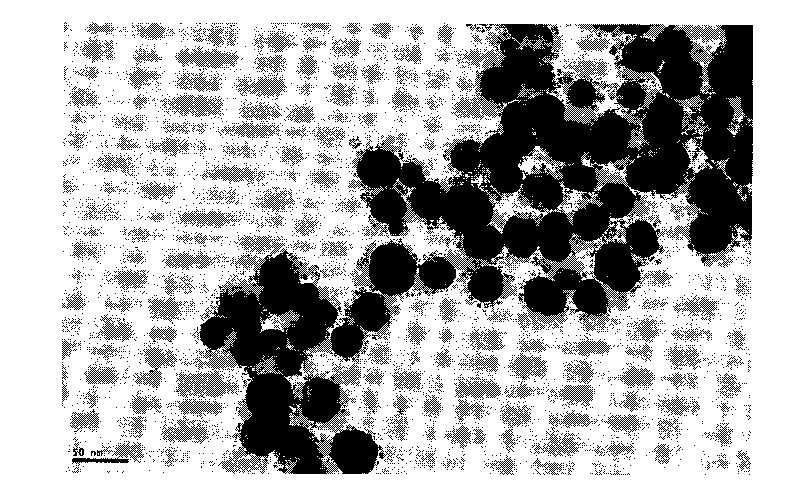

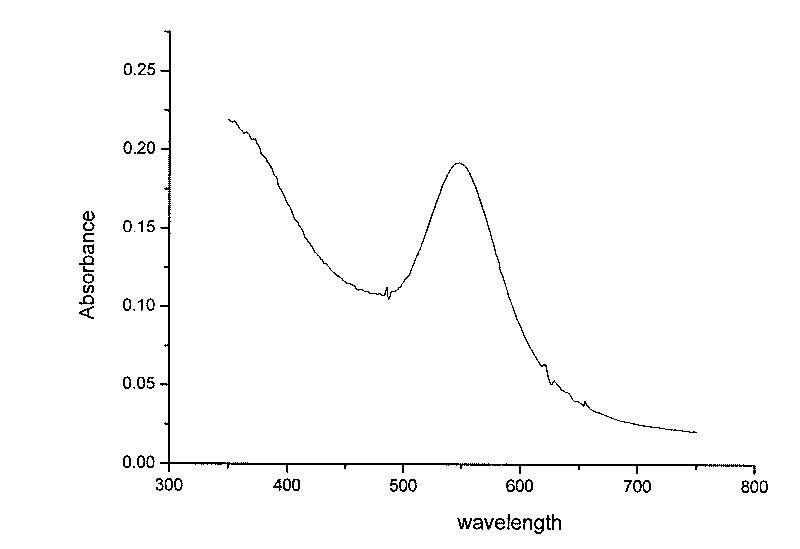

Composite particles whose nano magnetic iron oxide particles are assembled on surfaces of gold particles and method for preparing same

A nano-magnetic iron oxide, composite particle technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, inorganic material magnetism, etc., can solve the problems that have not been seen yet, and achieve the improvement of immobilization type and capacity, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Synthesis of oil-soluble Fe by hydrothermal method 3 o 4

[0026] Weigh 1.5gFeCl 3 ·6H 2 O, 1.0g FeCl 2 4H 2 0, 1.0g sodium oleate, mix it into the liner of 50ml hydrothermal synthesis kettle and put into stirring magnet, add 25ml ultrapure water, 3ml ethylene glycol, 3ml ethanol, the oleic acid of 2ml, hydrothermal The liner of the synthesis kettle was placed on a magnetic stirrer and stirred for 10 minutes to dissolve each component. Add 8ml of ammonia water into the hydrothermal synthesis kettle and stir for 20 minutes, take out the stirring magnet, put the liner into the hydrothermal synthesis kettle, and tighten the hydrothermal synthesis kettle. Put the hydrothermal synthesis kettle into an electric blast drying oven, and react for 10 hours at 170°C. Cool the reacted hydrothermal synthesis kettle to room temperature, take out the liner of the hydrothermal synthesis kettle, pour the sample into a beaker, add absolute ethanol, magnetically separate, pour t...

Embodiment 2

[0032] 1. Synthesis of oil-soluble Fe by hydrothermal method 3 o 4

[0033] Weigh 2.0gFeCl 3 ·6H 2 O, 1.0g FeCl 2 4H 2 O, 1.6g sodium oleate is mixed and poured into the liner of 100ml hydrothermal synthesis kettle and put into stirring magnet, add the oleic acid of 30ml ultrapure water, 10ml ethylene glycol, 10ml ethanol, 10ml, hydrothermal synthesis The liner of the kettle was placed on a magnetic stirrer and stirred for 10 minutes to dissolve the components. Add 10ml of ammonia water into the hydrothermal synthesis kettle and stir for 20 minutes, take out the stirring magnet, put the liner into the hydrothermal synthesis kettle, and tighten the hydrothermal synthesis kettle. Put the hydrothermal synthesis kettle into an electric blast drying oven, and react for 15 hours at 170°C. Cool the reacted hydrothermal synthesis kettle to room temperature, take out the liner of the hydrothermal synthesis kettle, pour the sample into a 200ml beaker, add absolute ethanol, magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com