ITO film sputtering target material cleaning method

A sputtering target and target technology, which is applied in the field of surface cleaning of ITO thin film sputtering targets, can solve problems such as difficulty in improving the cleanliness of sputtering targets, pollution of dust-free workshops, and increased manufacturing costs. The effect of nodulation on the surface of the material, improvement of product quality, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to more clearly set forth the structural features, technical means and the specific purpose and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings:

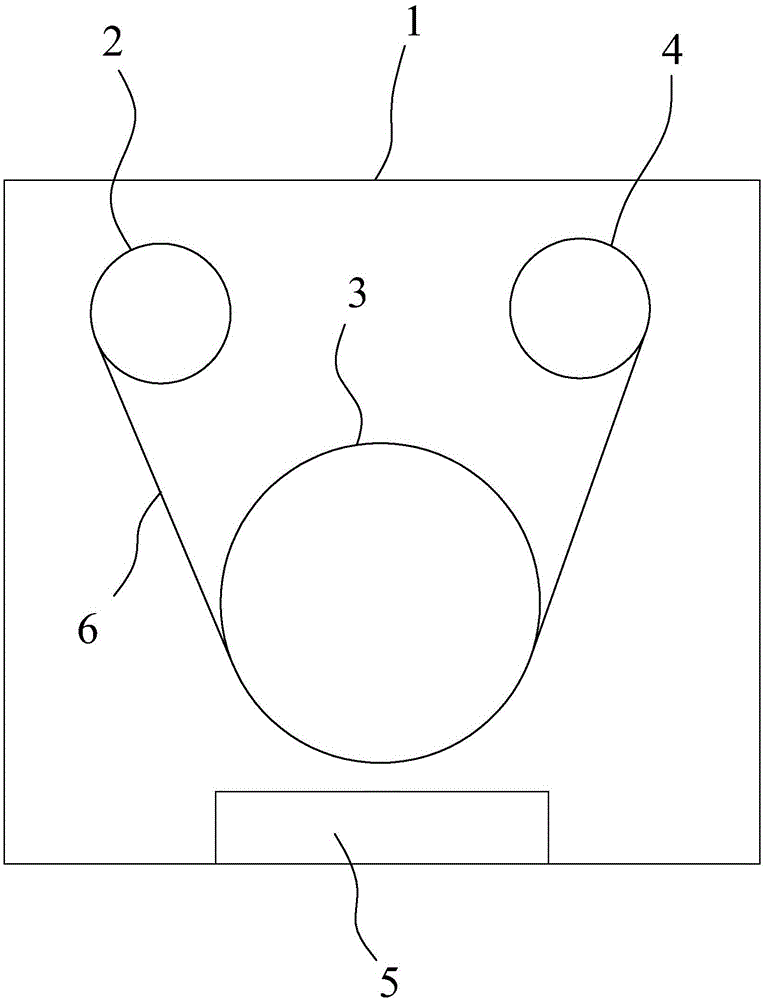

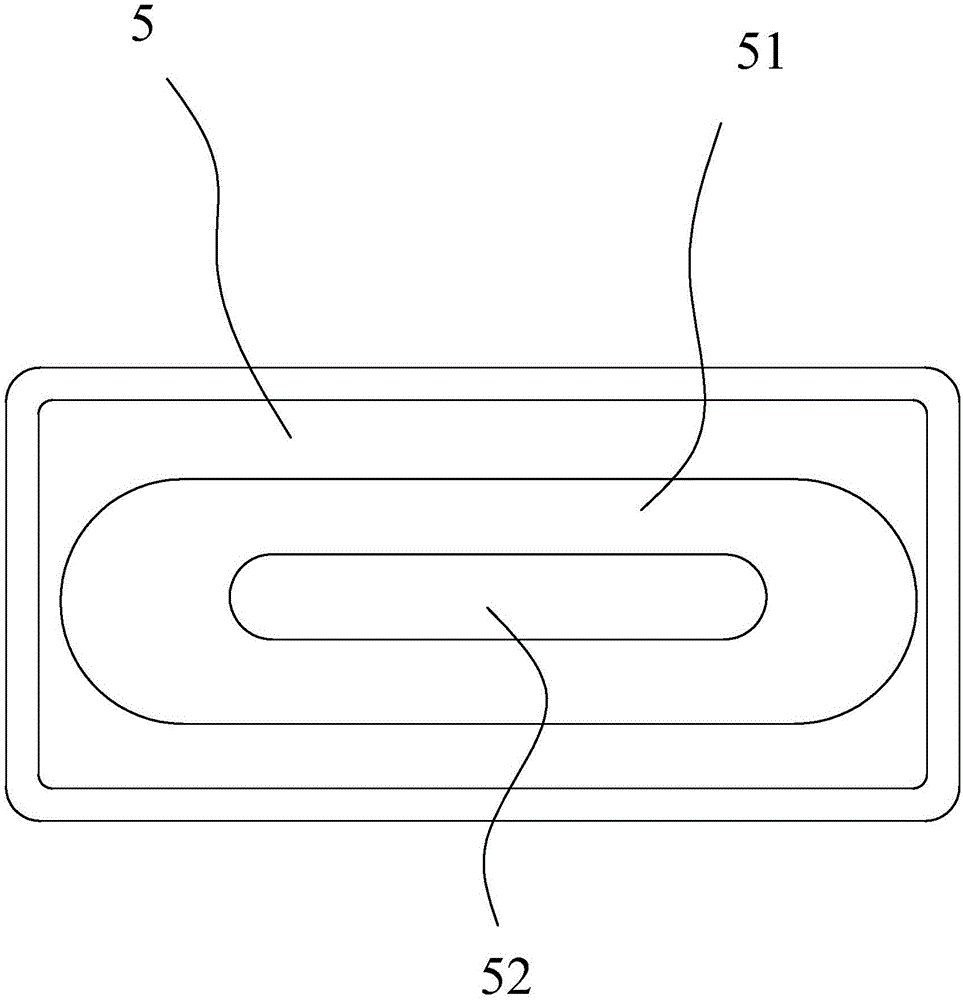

[0027] Such as figure 1 As shown, the device for ITO thin film sputtering production includes a sealed cavity 1, and an unwinding roll 2, a winding roll 4, a coating main roll 3 and a target 5 arranged in the sealed cavity 1, and the unwinding roll 2 and winding roll 3 are respectively located on both sides of the sealed chamber 1, the coating main roll 3 is located below between the unwinding roll 2 and the winding roll 4, and the target 5 is located directly below the coating main roll 3 , the substrate 6 on the unwinding roll 2 bypasses the lower end of the coating main roll 3 and reaches the winding roll 4 . During the film forming process, the impurities on the surface of the target 5 below are continuousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com