Anaerobic membrane bioreactor

An anaerobic membrane biology and reactor technology, which is applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of increasing treatment cost, affecting treatment effect, and running mud, etc., and achieves high treatment load, enhanced treatment efficiency, and high load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

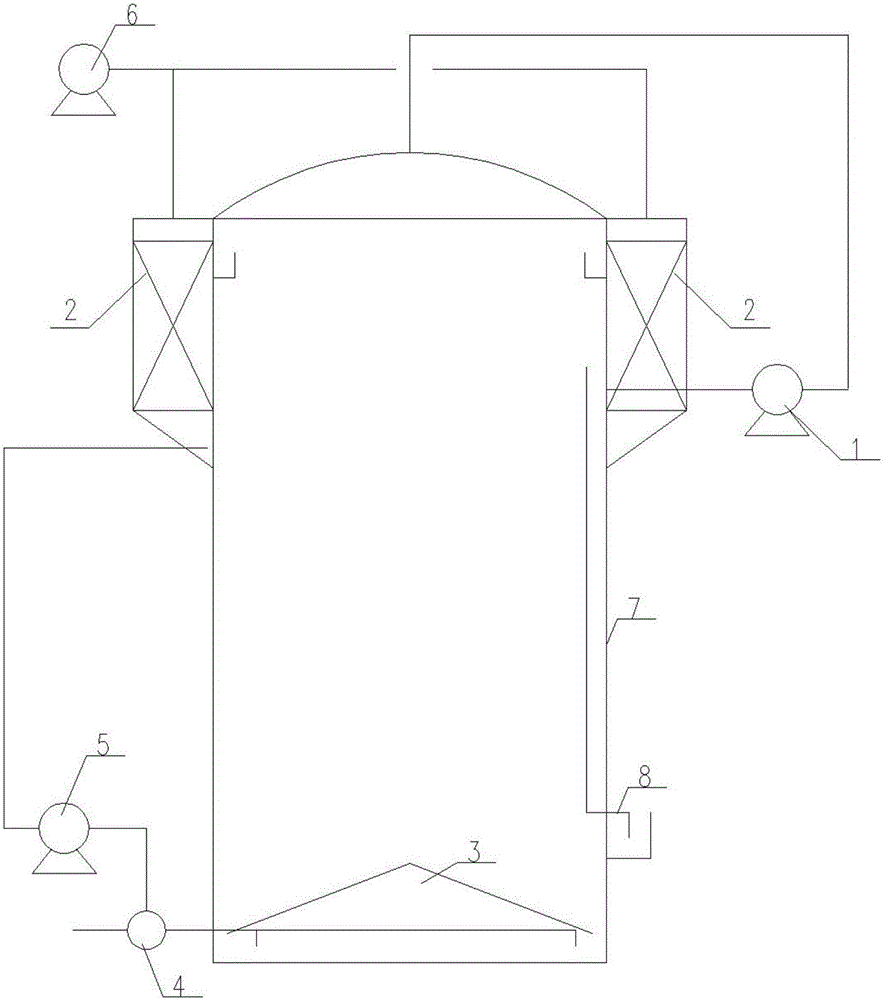

[0032] Such as figure 1 As shown, the anaerobic membrane bioreactor consists of a tank body 7, a swirl water distributor, a sampling device 8, an anaerobic membrane module 2, an anaerobic membrane module 3, a biogas booster pump 1, a circulation pump 5, an outlet pump 6 and Composition of 4 water packs. The upper opening of the tank body 7 communicates with the anaerobic membrane module 2, and the tank body 7 is connected to the sampling device 8 through several sampling pipes, and the sampling pipes are set at different heights of the tank body 7 to regularly monitor the amount of sludge in the tank body and the amount of sludge Traits provide guidance for the operation of the tank.

[0033] The anaerobic membrane module is composed of high-strength anti-pollution anaerobic hollow fiber membranes. The anaerobic hollow fiber membranes do not need to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com