Efficient aeration equipment

An aeration equipment and high-efficiency technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low oxygenation efficiency, peculiar smell, easy blockage, etc. The effect of rising, accelerating flow, and increasing dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

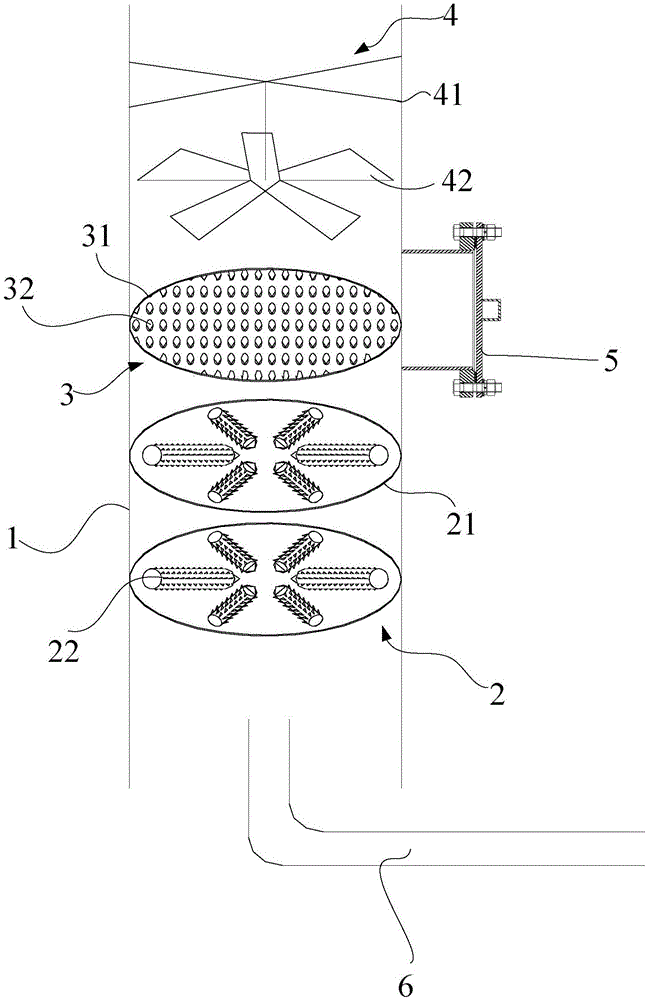

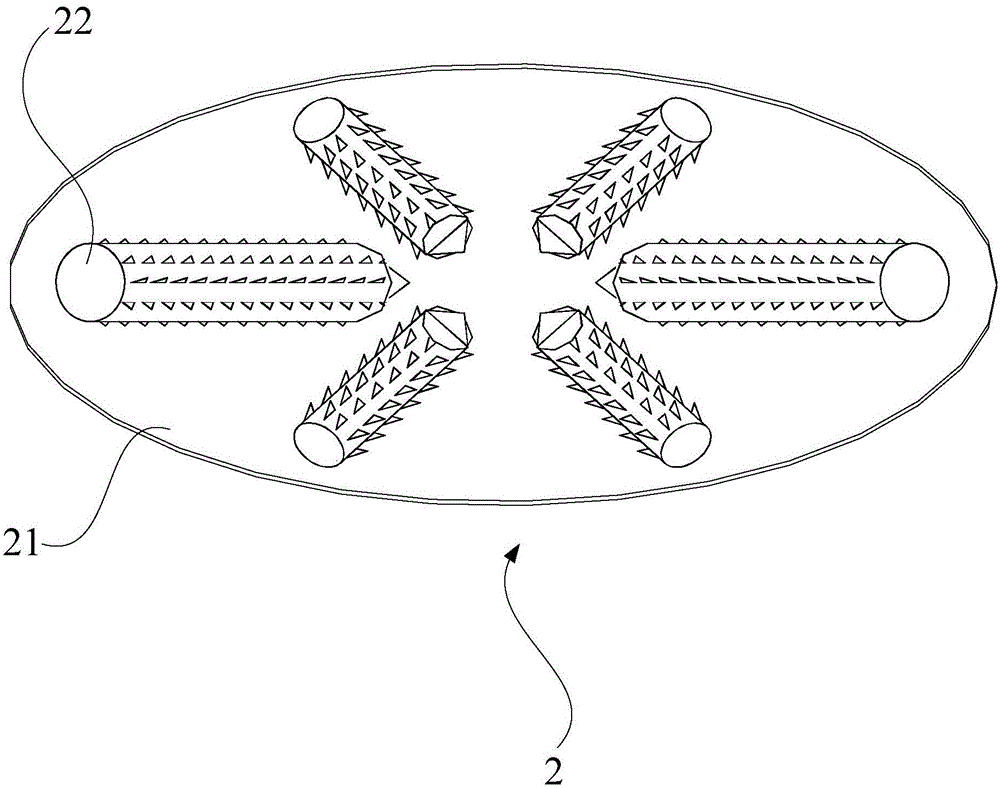

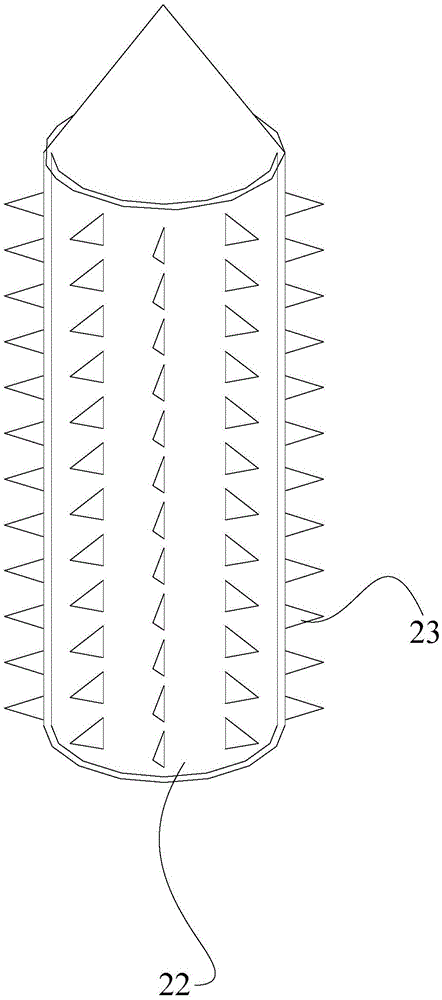

[0027] Example 1, such as figure 1 As shown, this embodiment provides a high-efficiency aeration device, including a cylindrical body 1 (the cylindrical body provided in this embodiment is a cylindrical structure with upper and lower openings, of course other shapes can also be used, but The cylindrical structure has the best effect), in the body 1, a cutting structure 2, a thinning structure 3 and an air diffusion structure 4 are sequentially arranged from bottom to top, wherein, the cutting structure 2 includes movable fixing (in this embodiment, the so-called When movable and fixed, it refers to a detachable fixing method) on the fixed frame 21 on the inner wall of the body 1 and the cutting roller 22 that is movably connected with the fixed frame 21 (the flexible connection expressed here means that the cutting roller can rotate on the fixed frame) , the cutting roller 22 is evenly distributed with cutting sheets 23 (by the setting of the cutting roller, after the gas ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com